Rogers RO4500 series microwave circuit PCB material is a high cost-effective PCB antenna-grade material of Rogers Company.

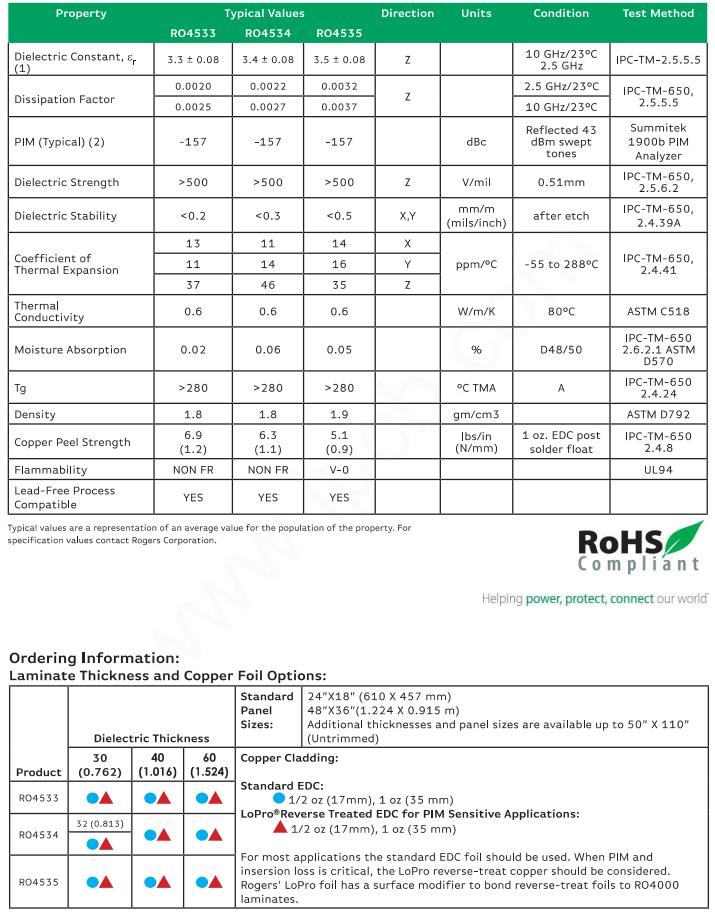

RO4500 series include RO4533, RO4534, and RO4535. This ceramic-filled, glass-fiber-reinforced hydrocarbon-based material group provides controlled dielectric constants, low loss performance, and excellent passive intermodulation response for mobile infrastructure microstrip antenna applications.

Like RO4350B and RO4003C high-frequency PCB materials, RO4500 materials are fully compatible with traditional FR-4 and high-temperature lead-free welding processes. These PCB materials do not require special treatment of traditional PTFE PCB materials to prepare electroplated holes. This range of products is an affordable alternative to more traditional PTFE antenna technology, allowing PCB designers to optimize the price and performance of Teflon PCB antennas. In addition, RO4533 and RO4534 are halogen-free materials to meet the strictest "green" standards. RO4535 uses RoHS-compliant flame retardant technology and is suitable for applications requiring UL94 V-0 certification.

The resin system of the RO4500 dielectric material is designed to provide the required performance for the ideal antenna performance. The thermal expansion coefficients (CTEs) in the X and Y directions are similar to those of copper. Good CTE matching reduces the stress of the printed circuit board antenna. Typical glass transition temperatures of RO4500 materials exceed 280 C (536 F), resulting in lower z-axis CTE and excellent pore permeability reliability. These characteristics, together with a size stability value of less than 0.05%, make RO4500 PCB the best candidate for printed circuit antenna applications. The RO4500 material also provides higher thermal conductivity than the equivalent PTFE/braided glass material, allowing the design of antennas with higher power handling capabilities.

In addition to these excellent thermomechanical properties, the RO4500 PCB material also reflects the electrical characteristics required by the PCB antenna designer. The dielectric constant (Dk) of the material is between 3.3 and 3.5 (+0.08), and the tangent of the loss angle (Df) measured at 2.5 GHz is 0.0020 to 0.0037. These values allow the PCB antenna designer to achieve considerable gain while minimizing signal loss. The material provided has low PIM performance and uses two 43 dBm sweep tones at 1900MHz, which is better than -155 dBC.

RO4533, RO4534, RO4535

RO4533, RO4534, and RO4535 Application:

Locomotive, Rail Transit, Power, Renewable Energy, Body and Chassis, Lighting, Equipment and Inverter Power, Defense Industrial Equipment, Car, Car Communications, Car Entertainment, Car Networking, Industrial Automation, Industrial Server, Indoor Lighting, Smart Home, Industrial Equipment Control, Mobile Phone Related, Electric Vehicle Power System, Communication Equipment, Internet of Things, Storage, Safety System, Cellular Infrastructure Base Station Antenna, WiMAX Antenna Network,

The intermodulation value (PIM) of microwave high-frequency PCB RO4533 is -157Bc, RO4725JXR is -166Bc and RO4730JXR is -164dBc.

At present, Rogers high-frequency circuit board materials have very rich products corresponding to different levels of application market and application requirements. The main feature of its products is high reliability and consistency. It is mainly divided into 92ML series, RO4725 hydrocarbon ceramics/RO4730 hydrocarbon ceramics series, RO4533 hydrocarbon ceramics/RO4535 series, AD300C/255C/250C series, etc. 92ML is mainly used in electronic applications requiring heat management. AD300C, AD255C, and AD250C are selected for mid-high and high-end diverse antennas, RO4725 and RO4730 are recommended for mid-high and low-end antenna markets, and RO4533 and RO4535 are recommended for mid-high and low-end markets.

RO4533 Hydrocarbon Ceramics/RO4535 Series

The RO4533/35 series is fully compatible with conventional FR-4 and high-temperature lead-free soldering processes. These microwave high-frequency PCBs do not require special pre-treatment as traditional PTFE materials do when preparing for plating through holes. Its main advantage is 1. LoPro copper foil brings excellent passive intermodulation (PIM) 2. Increase mechanical hardness relative to PTFE material. 3. Z-axis thermal expansion coefficient: 35, 37, 46ppm/C.