Reflow soldering,as one of the three core processes of SMT (Surface Mount Technology), is known in the industry as the ‘black box’ because of the hidden nature of its operation.Compared with the two visual processes of solder paste printing and component placement, the invisibility of reflow soldering makes it possible for industry experts to surmise the soldering process only on the basis of the soldering results after the oven and to optimise the parameters to achieve the desired results.

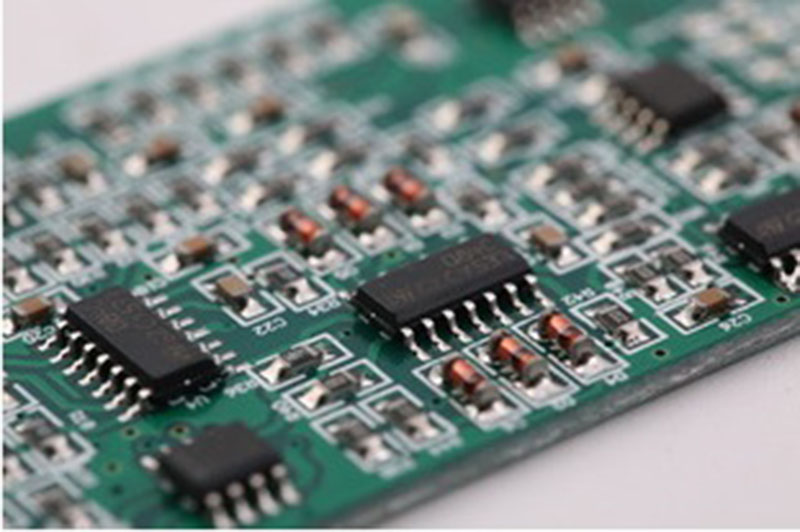

The working principle of conventional reflow soldering is based on the fact that the PCB (Printed Circuit Board) enters the reflow oven together with the printed solder paste and the mounted components, and is driven slowly into the oven chamber on rails.The upper and lower parts of the chamber can be heated, the early heating method is mainly infrared radiation, but now more use of hot air blowing into the chamber on the PCB, solder paste and components for heating.

Reflow soldering process is mainly divided into single-sided mounting and double-sided mounting two kinds.The process of single-sided mounting includes pre-application of solder paste, placement (either manually or automatically by machine), reflow soldering, and inspection and electrical testing.For double-sided mounting, it is necessary to complete the above process on the A-side, and then on the B-side for pre-applied solder paste, placement and reflow soldering, and finally for inspection and electrical testing.

The reflow process is a key soldering technology that connects the pins of electronic components to the PCB pads by melting the solder paste.In the manufacturing process of electronic products, the reflow soldering process is widely used, and its soldering quality has a direct impact on the performance and service life of the product.Therefore, strict control of the reflow soldering process is to ensure the quality of electronic products is a key link.

Temperature setting and measurement temperature profile is one of the core parameters of reflow soldering process.

The setting of the temperature profile should be adjusted according to the characteristics of the solder paste and the material of the PCB board.Typically, the temperature profile includes four parts: preheating zone, even heat zone, reflow zone and cooling zone.Preheating zone is used to preheat the PCB board and solder paste to a certain temperature, in order to eliminate internal stress and moisture; equalisation zone is used to maintain the temperature stability of the PCB board and solder paste; reflow zone is the key area of melting and curing solder paste, which requires precise control of temperature and time; cooling zone is used to quickly cool the solder joints to improve the mechanical strength and electrical properties of the solder joints.

Temperature profile setting and measurement of specific practices are as follows:

1.Trial production stage of new products, process engineers need to be based on product characteristics (PCB Gerber / parts temperature specifications) and its paste characteristics (manufacturers to provide the recommended temperature profile) to create a temperature measurement board and select the point, while setting up the parameters of the soldering furnace, and measure the appropriate temperature profile, the standardisation of the parameters of the soldering furnace and its development of a good curve control standards, in order to do the mass production of products as the standard process parameters;

2.Product mass production stage, the technician should be based on product production data in the conditions set production, and is responsible for measuring Profile, by the engineers in accordance with the temperature control standards to confirm the temperature profile and welding quality, if the test results do not match, then confirm the test point whether to stick firmly (not floating), and re-testing, if necessary, by the engineers to confirm the adjustments.

3.If there are conditions, you can consider the introduction of real-time temperature monitoring control: in the welding process, real-time monitoring of temperature changes in the furnace.This requires the use of high-precision temperature sensors and data acquisition systems to achieve.Through real-time monitoring of temperature changes in the furnace, you can find and correct temperature deviations and abnormalities, to ensure the stability and reliability of welding quality.

4.Temperature Measurement Cycle: Every time we change the line and every shift (continuous production of the same Model shall not exceed 12 hours), we need to measure the Profile, and if there is any doubt about the quality, we should test and confirm, and notify the relevant supervisor.

5.Requirements before measurement: Before temperature measurement, we should check the temperature measurement wire, if it is broken, we should replace it with a new one to ensure the accuracy of the measurement data.

Soldering furnace (Reflow) control points:

1.The upper limit of oxygen concentration control of the machine ≦1000ppm (Note: Customers have special control in accordance with the SOP definition), and recorded in the ‘Reflow Furnace Panel Temperature Inspection Record Sheet’ every 2 hours.

2.When changing the line for mass production, we will set up the conditions according to the production conditions of each machine type, and confirm and record it according to the item ‘Reflow line change check list’.

3.In order to effectively control the Flow process,the production unit registers the temperature in the ‘Reflow Oven Panel Temperature Check List’ every 2 hours after the wire change.

4.Temperature testers are sent to the calibration room for regular calibration,and during the monthly maintenance of the Reflow, the standard fixtures are confirmed and recorded in the CPK control sheet.

5.The temperature measuring board should be updated regularly (every 3 months) and when the measured temperature difference exceeds ±5℃.Or use more than 50 times and the measured temperature difference exceeds ± 5 ℃ need to be updated.

6.Reflow temperature zone actual value and set value control within ±5℃.If this specification is exceeded, it is necessary to stop feeding the board and then notify the process engineer to make adjustments.

Reflow soldering as a key link in the SMT process, process control and quality management for the performance and life of electronic products has a critical impact.Through scientific and reasonable setting of the temperature curve, the implementation of real-time temperature monitoring and strengthen the control of the reflow oven and other measures, we can effectively improve the reflow soldering quality, so as to ensure the stability and reliability of electronic products.