Place the image produced by an imaging system to appear in an object in the field of view, and use it as a reference point or measurement.

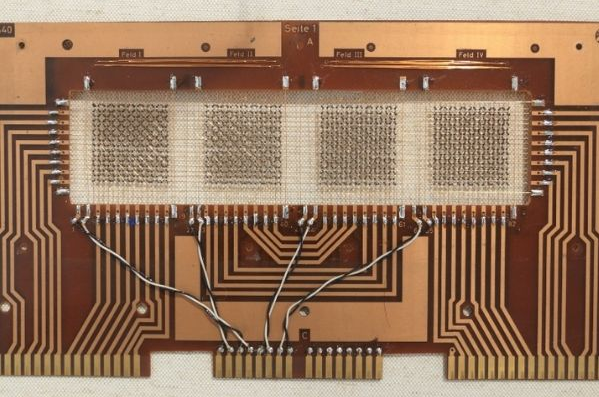

In other words, the benchmark helps the machine to identify an object in its space, PCB and PCBA circuit board assembly. This means that our screen printer, placement machine, AOI machine can recognize the PCB board and PCBA board when performing tasks.

We encourage customers to use 3 benchmarks. If you can’t use 3 benchmarks, 2 benchmarks are generally sufficient, but 3 benchmarks are the best, each serves a purpose.

The first benchmark of PCB factory smt technology helps the machine to identify the X and Y coordinates of the PCB in its space.

The second benchmark helps the machine identify what positioning PCB is and how it is clamped with the tilted PCB. If the PCB is rotated or even 1/10 degree, this will completely destroy the components. If it is not a benchmark, the machine can measure the angle, and the board rotates the machine to the nearest one. 1/ The position of the first Baidu is compensated accordingly.

Third and finally, the third reference point helps the machine to compensate for any shrinkage or expansion of the PCB. Yes, I believe it or not the PCB is different. The PCBA is very small in a long enough distance, which is for larger PCBs. It is very important because they have experienced a greater amount of stretching and/or shrinking. This is particularly true for double-sided SMT components. On the first side of the reflow oven, the board may elongate, shrink, bow, or bend, regardless of What do you want to call it, there is a third benchmark that can help compensate for this effect.

The planning of the PCB circuit board mainly comes from the layout planning, which requires the layout of internal electronic components, metal connections, through holes and external connections, PCB circuit board electromagnetic protection, heat dissipation, crosstalk and other factors, excellent Circuit planning can save production costs and achieve outstanding circuit functions and heat dissipation. Why PCB circuit boards have always been favored by everyone.

1. High reliability: We will go through a series of inspections, tests and aging tests to ensure that the PCB circuit boards work reliably for a long time.

2. High-density: For decades, high-density printed circuit boards have been able to develop along with the improvement of integrated circuit integration and the advancement of mounting technology.

3. Producibility: The chip factory adopts modern management, which can be standardized, planned (quantified), automated, etc., to ensure the consistency of product quality.

4. Testability: A relatively complete test method, test specifications, various test equipment and instruments have been established to detect and appraise the eligibility and service life of PCB circuit board products for PCB proofing.

5. Plannability: The requirements for various functions (electrical, physical, chemical, mechanical, etc.) of PCB circuit boards and PCBA circuit boards can be standardized and standardized to complete the printed circuit board planning, which is short in time and high in efficiency.