How to cut printed circuit board is one of the crucial steps in the PCB manufacturing process. This process requires a combination of precise techniques, appropriate tools, and careful consideration of the PCB’s characteristics. Cutting a PCB is a delicate operation that affects the quality of the final product. The goal is to ensure that the cutting process does not compromise the integrity of the circuit or lead to any issues that could affect its performance later.

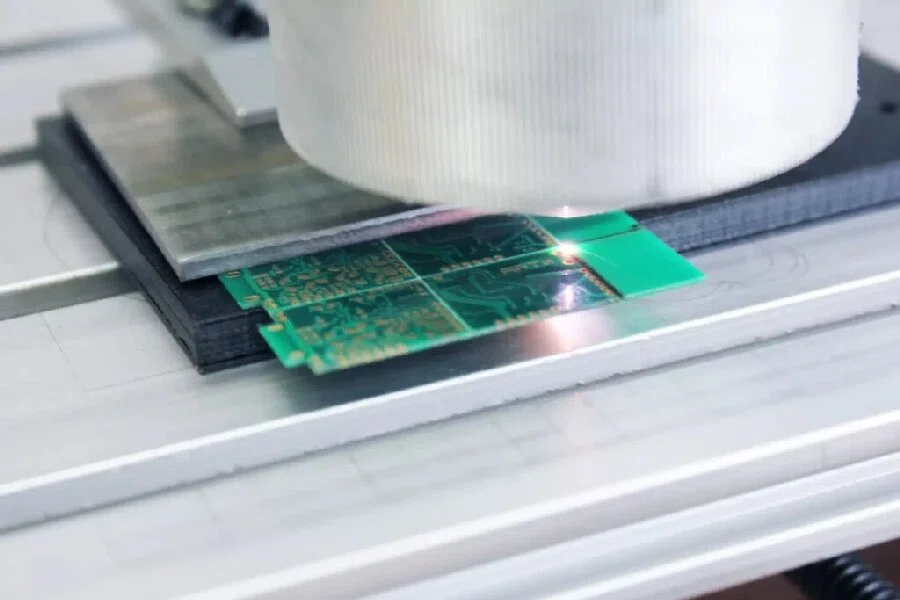

The first step is selecting the appropriate tools for the job. The tools you choose depend largely on the scale of production and the complexity of the PCB. For small-scale or prototype runs, manual tools such as utility knives or scissors may be sufficient. However, for more precise or larger production runs, mechanical or automated tools are recommended.Laser cutting machines are a popular choice for cutting PCBs in high-precision environments. Laser cutting offers exceptional accuracy and is capable of cutting intricate and detailed designs without physical contact, which reduces the risk of damage. For medium-scale production, CNC routers are often used. These are automated machines that use rotating cutting tools to precisely remove excess material from a PCB, ensuring that edges are smooth and clean. CNC routers are highly versatile, able to handle complex geometries and produce consistent results over long production runs.

How to cut printed circuit board

How to cut printed circuit board also involves understanding the material and layers used in PCB manufacturing. PCBs are generally made of rigid materials like FR4, but there are flexible and rigid-flex variants that require different cutting techniques. Rigid PCBs are more straightforward to cut using traditional methods like laser cutting or CNC routing.

Additionally, some PCBs may have multiple layers, including copper traces and solder masks. Cutting through multiple layers requires precise alignment and control to ensure that the cuts do not damage any internal circuitry. If there are components mounted on the board, they must also be taken into account during the cutting process to avoid causing damage to the components.

When considering how to cut printed circuit board, the accuracy of the cut is paramount. Any deviation from the intended cut can result in the failure of the circuit board or its components. Therefore, measuring the dimensions of the PCB and ensuring that the cutting equipment is properly calibrated is crucial to avoid any errors.Before cutting, it’s essential to review the PCB design layout thoroughly. The design will outline the exact dimensions and shapes required for the final board. For large-scale or complex designs, it’s often beneficial to test cut a sample PCB before beginning the full production run. This helps to ensure that the cutting tool is properly set up and can produce the desired result consistently.

When determining how to cut printed circuit board, one of the most important considerations is planning the cutting path. For boards with multiple layers, it’s essential to avoid cutting through sensitive areas like traces or vias. If the cutting path is planned incorrectly, it may damage the internal layers or compromise the functionality of the board.For multi-layer boards, it’s also important to consider the direction in which the layers are stacked. Cutting along the correct axis will ensure that the cuts are precise and avoid cutting into the layers unnecessarily. In some cases, it may be necessary to use a multi-pass cutting technique, where the PCB is cut in stages to prevent excessive heat buildup or material warping.For PCBs with sensitive components, care must be taken to avoid cutting near the components themselves. Depending on the design, components can be damaged by cutting tools if they are too close to the cutting edge. In these cases, careful planning is essential to avoid damaging both the board and its components.There are several post-cutting steps that need to be considered. First, the edges of the PCB should be inspected for any roughness or burrs that could affect the overall quality of the board.To remove burrs and smooth out the edges, manufacturers often use a deburring tool or polishing machine. These tools help to ensure that the edges are smooth and free from any imperfections that could interfere with the assembly process or cause issues during later stages of PCB production.

In conclusion, how to cut printed circuit board is a critical process in the PCB manufacturing journey. Whether you're working with a simple single-layer PCB or a complex multi-layer design, cutting requires precision, care, and the right tools. By understanding the different methods and tools available, such as manual cutting, laser cutting, and CNC routing, you can ensure that the cutting process goes smoothly and that your PCB is ready for the next steps in production.