The CRT TV PCB board has always played a crucial role in electronic product design, particularly in the television sector during the late 20th century. Although LED and LCD screens have taken over the market today, CRT TVs still retain their charm, and the PCB board design within them is worth exploring. As the core component for circuit connection, the PCB board in CRT TVs not only ensures stable image display but also maintains the efficient operation of the circuitry. This article will explore the design, manufacturing, and application value of CRT TV printed circuit boards in modern electronics.

CRT TV PCB board is one of the most important components in traditional television sets. It is responsible for transmitting electronic signals to the display, forming images. The design of the PCB directly affects image quality and the durability of the device. In the early CRT TVs, PCB boards were designed with a single layer, with simple yet effective circuitry that catered to the technological demands of the time. As time progressed, PCB technology advanced, and multilayer PCBs gradually became mainstream. However, CRT TV printed circuit boards still maintain their unique design requirements, ensuring circuit stability and high performance.CRT TV printed circuit board manufacturing has evolved significantly over the past few decades. Early CRT TV sets relied on manual soldering and simple circuit designs, while modern production processes depend more on automated machinery and precise design tools. With technological advances, PCB materials and structures have become more refined and complex. Particularly in terms of temperature management and current distribution, modern PCB board improvements have significantly enhanced the efficiency and longevity of CRT TVs.

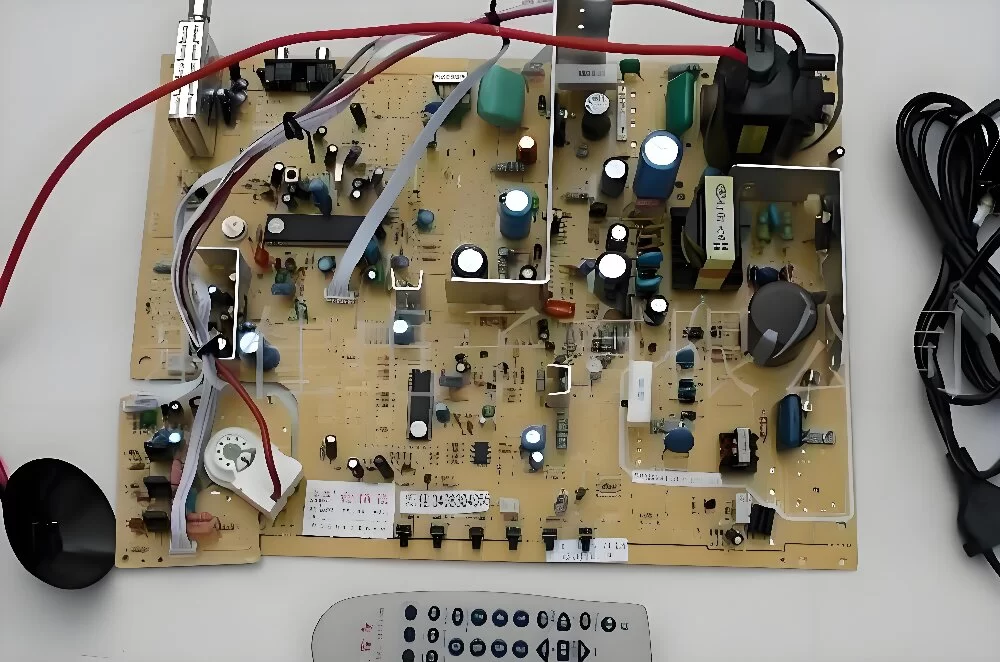

CRT TV PCB board

CRT TV PCB board typically feature a single or double-sided copper foil layer design. Although it may seem simpler compared to modern multilayer PCBs, this structure can still meet the high-voltage operating requirements of CRT televisions. To ensure the stability of long-term operation, additional anti-static and moisture-resistant treatments are applied to the PCB board. These designs not only extend the lifespan of the PCB but also improve the image quality of the television, ensuring consistent performance in various environments.CRT TV printed circuit board material selection is critical. Traditional PCBs often used FR-4 material, known for its excellent heat resistance and electrical insulation properties, ensuring circuit safety in high-temperature working conditions. In addition to material considerations, engineers must also ensure signal stability and interference resistance. To prevent external signal interference from affecting CRT TV images, the circuit layout on the PCB board must be precise down to the micron level, ensuring every circuit node functions effectively.

CRT TV PCB board design also requires careful attention to heat dissipation. Since CRT TVs generate significant heat during operation,the PCB must be designed with adequate ventilation and thermal management to prevent overheating and ensure the long-term stability of the system. Modern CRT TV designs incorporate better thermal materials and heat sinks to improve the overall performance of the TV and extend the lifespan of its components.As CRT technology has matured, the focus on durability and longevity of CRT TV printed circuit boards has increased. Engineers have been refining circuit designs to ensure that the boards can handle prolonged operation without degradation. One key area of focus is the power supply circuits, where precision in voltage control and efficient energy management is critical to prevent malfunction and prolong the lifespan of the TV.In the context of environmental protection and sustainable electronics, the design of CRT TV printed circuit boards also contributes to minimizing electronic waste. By utilizing durable materials and improving circuit efficiency, manufacturers can reduce the number of discarded TV sets and prolong their usable life. This focus on sustainability is important in today’s electronics industry, as it aligns with global efforts to reduce waste and develop greener technologies.

The signal integrity of CRT TV printed circuit boards is another area that has undergone continuous improvement. By refining the layout of signal pathways and optimizing the placement of key components, modern PCB designs minimize interference and signal loss. This results in clearer images, better color accuracy, and overall improved viewing experiences for users of CRT TVs, despite the rise of more modern display technologies.While CRT TVs may be considered a legacy technology, the lessons learned in PCB design during their development have carried over into the design of modern electronic devices. The precision required for high-voltage circuitry, the attention to thermal management, and the need for durability are all factors that remain relevant in today’s advanced PCBs for cutting-edge technologies.

CRT TV PCB board are not just the heart of classic electronic devices, they represent a pivotal moment in the history of technology development. While CRT TVs have gradually been replaced by newer technologies, the design experience and technical knowledge gained from these PCB boards remain highly influential in today’s circuit board design. Through constant innovation and technological optimization, PCB board design has not only enhanced device performance but also laid the groundwork for the future of technology development.