The 2 layer flexible printed circuit board is an essential component in modern electronics, offering unique flexibility and a dual-layer design that meets the high demands of complex devices. Compared to traditional rigid circuit boards, the 2-layer FPC offers significant advantages in flexibility, weight, and space. Whether in consumer electronics, medical devices, or aerospace, the 2-layer flexible PCB continues to drive technological innovation.

The 2 layer flexible printed circuit board provides a reliable solution for complex circuitry systems. It consists of two conductive layers connected through a flexible substrate, allowing for more intricate circuit layouts. At the same time, the use of flexible materials enables it to fit into various shapes, making it the top choice for devices that are becoming increasingly miniaturized. Compared to multilayer boards, 2-layer FPC offers substantial cost and production time benefits, making it a versatile solution for many industries.2-layer f FPC board production technology is rapidly advancing. As material science and manufacturing techniques improve, the thickness of 2-layer FPCs can be further reduced without compromising electrical performance or mechanical strength. This has led to its widespread adoption in consumer electronics such as smartphones and wearables. Additionally, its usage in medical devices has been growing year by year, especially in monitoring equipment and implantable devices.2-layer f FPC boards are not just limited to consumer electronics. They are also widely used in the automotive and industrial control sectors. In these fields, 2-layer FPCs are deployed in engine management systems, sensors in autonomous driving systems, and other key components. Due to their lightweight, compact, and durable nature, they can provide reliable performance in high-temperature and high-stress environments, making them ideal for these demanding applications.

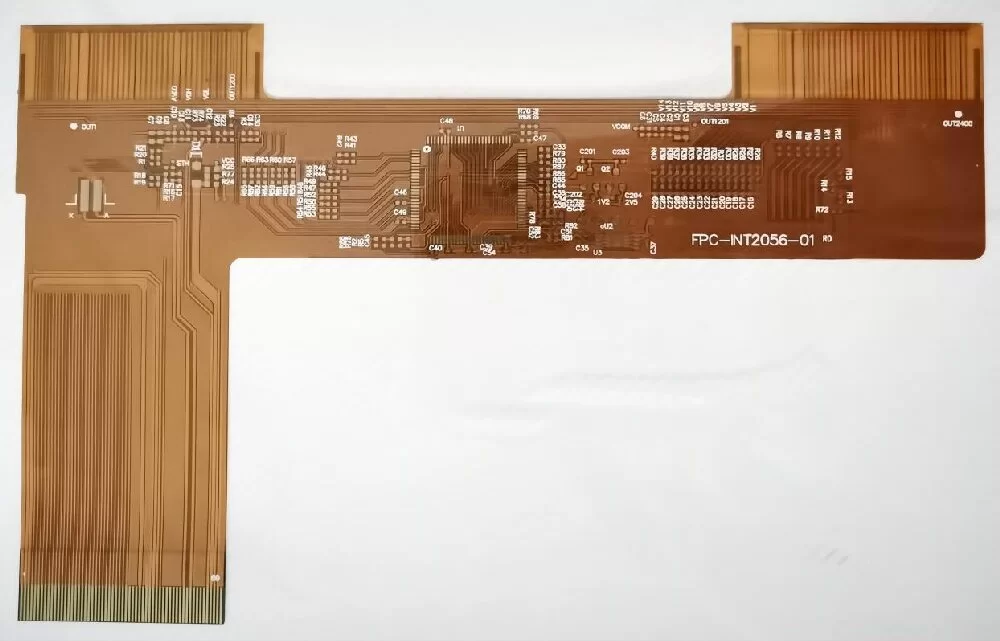

2 layer flexible printed circuit board

The future of 2 layer flexible printed circuit board looks promising. As flexible electronics technology continues to evolve, the design and application of 2-layer FPCs will become broader and more complex. With the advent of 5G and the Internet of Things (IoT), there will be increased demand for 2-layer flexible PCBs, particularly in devices requiring high-frequency signal transmission and compact spaces. The unique properties of flexible PCBs make them an indispensable part of future electronic product design.2-layer FPC boards are becoming increasingly crucial as electronic devices push the boundaries of design and functionality. In wearable technology, these PCBs allow for compact, flexible, and lightweight devices that provide comfort and durability. Moreover, the ability to integrate a variety of sensors and connectors makes the 2-layer FPC an ideal choice for manufacturers who prioritize performance, user experience, and cost-efficiency in their products.

Sustainability is another significant advantage of 2-layer FPC boards. The materials used in manufacturing FPCs, such as polyimide, are environmentally friendly and contribute to the reduction of electronic waste. The flexibility and durability of 2-layer PCBs reduce the need for frequent replacements, contributing to a longer product lifespan and fewer discarded components in the environment.

2 layer flexible printed circuit board also offer enhanced thermal management capabilities. The flexible nature of the FPCs allows for more efficient heat dissipation, making them ideal for use in applications where maintaining a low operating temperature is critical. This feature is particularly advantageous in high-performance computing systems, where heat can become a limiting factor for efficiency and speed.In the field of medical electronics, 2-layer flexible printed circuit boards are opening up new possibilities for more advanced and minimally invasive medical devices. The flexibility, biocompatibility, and lightweight nature of FPCs make them ideal for applications in wearable medical technology, such as continuous glucose monitors or smart health patches that track vital signs in real-time.In aerospace and defense industries, 22-layer FPC boards are used for high-reliability applications that demand durability and adaptability. The ability to withstand extreme temperatures, vibrations, and harsh environmental conditions makes these PCBs ideal for satellite communication systems, unmanned aerial vehicles (UAVs), and missile guidance systems.2-layer FPC boards are also contributing to the development of next-generation communication devices. The 5G revolution, with its emphasis on faster, higher-frequency communication, has increased the need for flexible circuit boards that can handle the demands of modern telecommunications equipment. The adaptability and performance of 2-layer FPCs make them a perfect match for this fast-evolving field.

The 2 layer flexible printed circuit board represents a breakthrough technology in electronic design, combining flexibility and efficiency to offer a wide range of applications. From consumer electronics to industrial applications, the 2-layer FPC demonstrates superior performance in multiple fields. As technology advances, 2-layer FPCs will play an increasingly important role in future electronics, providing innovative solutions for modern design challenges.