Rogers PCB laminate plays a pivotal role in modern electronic manufacturing, especially in high-frequency and RF circuit designs where its superior electrical performance, low dielectric loss, and stable dielectric constant make it a preferred choice. Compared to traditional FR4 materials, Rogers PCB Copper Clad Laminate offers enhanced signal integrity and reduced insertion loss, ensuring optimal performance in high-frequency applications.In high-frequency circuit designs, the stability of Rogers PCB Copper Clad Laminate is crucial. Traditional FR4 materials underperform at high frequencies due to changes in dielectric constant and increased signal loss, whereas Rogers PCB Copper Clad Laminate maintains consistent electrical performance. Its low dielectric constant and low loss factor make it ideal for RF circuits, microwave circuits, and high-speed digital circuits. Moreover, Rogers PCB Copper Clad Laminate retains excellent performance at high temperatures, making it suitable for applications that require high thermal resistance, such as aerospace and military equipment.

Rogers PCB laminate also demonstrates outstanding mechanical properties in PCB manufacturing. It offers excellent dimensional stability and a low coefficient of thermal expansion, effectively reducing warping and delamination in multilayer board structures. This material can maintain stable performance across various temperature ranges, ensuring the reliability of multilayer boards in complex environments. For circuit designs that demand high precision and stability, Rogers PCB Copper Clad Laminate is undoubtedly the ideal choice.For circuits that need to operate in diverse environments, Rogers PCB Copper Clad Laminate provides exceptional reliability. Its low moisture absorption characteristic ensures excellent performance even in humid conditions. Rogers PCB Copper Clad Laminate maintains its electrical and mechanical properties in extreme temperature and humidity conditions, which is crucial for communication equipment, satellite systems, and other high-end applications that require long-term stability.As electronic products continue to evolve towards miniaturization and higher performance, the requirements for PCB materials are becoming increasingly stringent. Rogers PCB Copper Clad Laminate meets these demanding needs by offering higher signal speeds and lower losses. In the future, with the development of 5G, IoT, and other emerging technologies, Rogers PCB Copper Clad Laminate will continue to lead industry innovation, bringing more possibilities to electronic design.

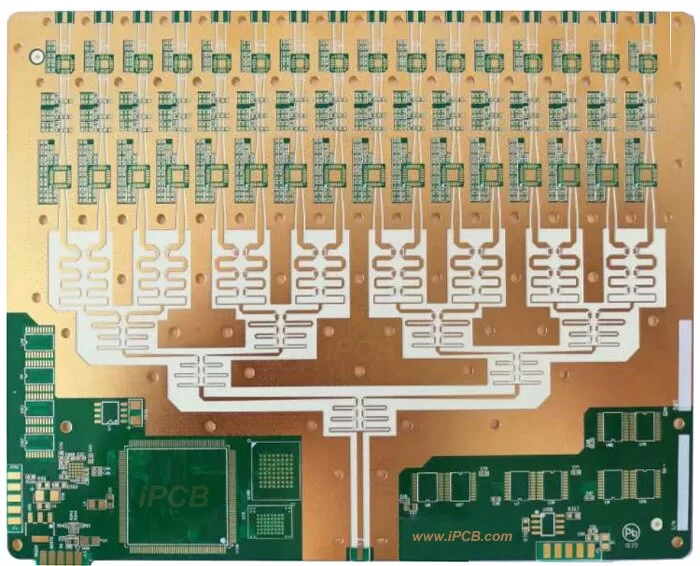

Rogers PCB laminate

Rogers PCB laminate stands out for its unmatched electrical performance, crucial for high-frequency and high-speed applications. The material's low dielectric constant and low loss tangent are key factors that contribute to excellent signal integrity, minimizing signal loss and ensuring high-frequency signals travel efficiently through the circuit. This characteristic is particularly valuable in RF and microwave applications, where maintaining signal clarity and strength is paramount. Additionally, the consistency of Rogers PCB Copper Clad Laminate's dielectric properties over a wide frequency range means that designers can rely on predictable and repeatable performance. This consistency is not as easily achievable with traditional materials like FR4, which can exhibit significant variations in performance at higher frequencies. The use of Rogers PCB Copper Clad Laminate thus simplifies the design process, allowing engineers to focus on optimizing circuit functionality without worrying about material-related signal degradation.

Rogers offers a range of laminate materials, each tailored to specific application needs, providing designers with great flexibility in material selection. Options like Rogers RT/duroid® 6002, 5880, and 4350B cater to different requirements, from ultra-low loss and high-frequency performance to cost-effective solutions for less demanding applications. This variety allows engineers to select the most appropriate material based on the specific demands of their project, optimizing both performance and cost.

While Rogers PCB laminate offers numerous advantages, there are challenges associated with its use. One primary concern is cost; Rogers materials are generally more expensive than traditional options like FR4. However, the superior performance they provide often justifies the additional expense, especially in high-frequency and mission-critical applications where performance cannot be compromised.Another challenge is the learning curve associated with working with Rogers materials. Designers and fabricators may need additional training and experience to fully leverage the benefits of these advanced laminates. Understanding the specific processing requirements, such as handling, drilling, and bonding, is crucial to achieving optimal results.Looking ahead, the demand for Rogers PCB Copper Clad Laminate is expected to grow as technologies such as 5G, IoT, and advanced driver-assistance systems (ADAS) continue to evolve. These technologies require increasingly sophisticated PCB solutions that can handle higher frequencies, more complex signal processing, and greater thermal demands. Rogers' ongoing innovation in laminate materials positions it well to meet these emerging challenges, continuing to support the cutting-edge developments in electronics.

In conclusion, Rogers PCB laminate is a cornerstone of modern high-performance PCB design and manufacturing. Its unique combination of electrical, thermal, and mechanical properties makes it ideal for a wide range of advanced applications. As the industry continues to push the boundaries of what is possible, Rogers PCB Copper Clad Laminate will undoubtedly remain at the forefront, enabling the next generation of electronic innovations.