Rogers PCBs are widely used in high-frequency circuit design due to their superior electrical performance and thermal stability. During the rogers pcb fabrication process, there are several critical steps and considerations that require special attention to ensure product quality and performance.

1.Material Selection

Material selection is a critical step in the Rogers PCB fabrication process.The composition and structure of Rogers boards directly affects their performance and quality. Different models of Rogers materials (such as RO4003C, RO4350B) have different dielectric constants and loss characteristics, so you need to choose the right material according to the specific application requirements to ensure the high performance and reliability of the board.

2.Manufacturing process

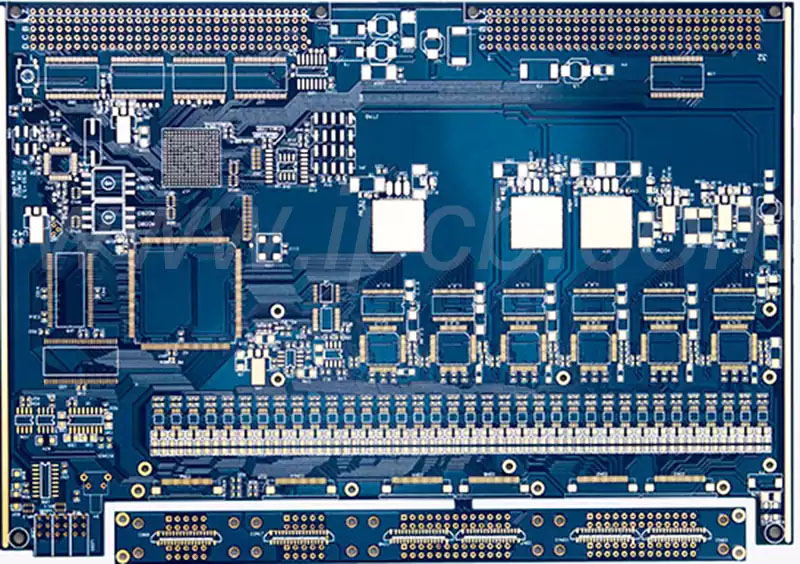

The manufacturing process includes a number of steps such as material selection, inner layer processing, lamination, drilling, copper plating, etching, decontamination and coating of soldermask. Each step is critical to the final quality of the PCB.For example,in the lamination process, the application of high-temperature lamination technology requires precise control to prevent material deformation and delamination.

3.Inner layer processing and lamination

During inner layer processing, special attention should be paid to the fineness and accuracy of the graphics to ensure the integrity of the circuit design.From the inner layer to the outer layer of the lamination process,reasonable pressure and temperature control can optimize the fusion of materials to enhance the mechanical and electrical properties of the circuit board.

4.Drilling and Copper Plating

Drilling is the key to connecting the circuits between the different layers, and high-precision equipment is used to avoid deviations in the hole diameters.The subsequent copper plating must be of uniform thickness to ensure good electrical conductivity.The effects of temperature,time and chemical composition of the copper plating process also need to be strictly controlled.

5.Etching and decontamination

During the etching step, it is necessary to ensure the selection of the appropriate chemical solution and the correct time to avoid over-etching or under-etching, which may affect the integrity of the line. After completing the etching, a thorough decontamination process is necessary to remove residual chemicals.

6.Coating soldermask

The soldermask coating protects the circuit from the external environment and prevents short-circuiting during the soldering process. This process ensures the uniformity and integrity of the coating to improve the reliability of the PCB.

7.Quality control and testing

Upon completion, Rogers pcb fabrication is subjected to rigorous quality control and testing, including automated optical and X-ray inspections to verify electrical performance and structural integrity. At the same time, impedance control and various test reports according to specifications should not be ignored.

Quality control measures during the Rogers PCB fabrication.

1.Risk Management and Design Review

Implementing risk management in the manufacturing process is critical. By identifying problems that could lead to additional costs, product failures or delays before manufacturing begins, companies are able to take preventative measures to reduce the impact of risk. In addition, design audits ensure that the design meets the requirements of the manufacturing process and can effectively minimize subsequent problems caused by poor design.

2.Incoming Quality Control (IQC)

Incoming Quality Control (IQC) of all raw materials and components prior to PCB production is a basic and effective measure. This approach involves testing of purchased materials to ensure that the materials used meet established quality standards, minimizing potential future failures and problems at the source.

3.Process Monitoring and In-Line Inspection

During the manufacturing process,problems can be identified and corrected in real time by implementing process monitoring and in-line inspection. Regular process audits are conducted to ensure that each stage of production complies with standard procedures,thus improving overall product quality.

4.Functional Testing and Prototype Verification

Establishing a rigorous testing program, including functional testing and prototyping, is an effective way to ensure that PCBs work prch not only saves time and money, but also better control the quality of the final product.

5.Follow industry standards and certifications

Ensuring compliance with relevant industry standards and quality certifications (e.g. ISO, UL, etc.) is an effective quality control measure.

Standardized production processes and material selection ensure that the PCBs manufactured meet safety and performance requirements and increase customer trust.

6.Regular training and knowledge updatingRegular training for employees reinforces their understanding and implementation of quality control processes and ensures that every employee is effectively involved in quality management.This is an important human resource input to improve manufacturing quality.

In the process of Rogers pcb fabrication,each link is indispensable,and only by strictly controlling each step can we ensure the high quality and excellent performance of the final product.From the selection of materials to the careful management of the manufacturing process,to the implementation of quality control measures as they are implemented, all of this lays the foundation for the success of Rogers PCB in high-frequency circuit applications.