Breadboard circuit is a crucial tool in electronic design, playing an indispensable role during the prototyping and circuit testing phases. As a fundamental tool in electronic design, the Breadboard PCB is widely used in education, research, and product development across various fields. Its ease of use and efficiency in building prototypes allow engineers and developers to quickly validate design concepts.

Breadboard circuit is often used during the design verification stage of circuit prototypes. This method allows developers to quickly assemble and test circuits without soldering, ensuring the functionality of the design. During this process, a Breadboard PCB provides engineers with a flexible testing environment, enabling them to swiftly identify and resolve design issues. This flexibility extends beyond simple prototyping and can be applied to more complex circuit systems. During development, engineers can rapidly modify and optimize circuit designs using a Breadboard PCB without spending significant time and resources on remaking a PCB. This ability to quickly iterate greatly accelerates the product development process.

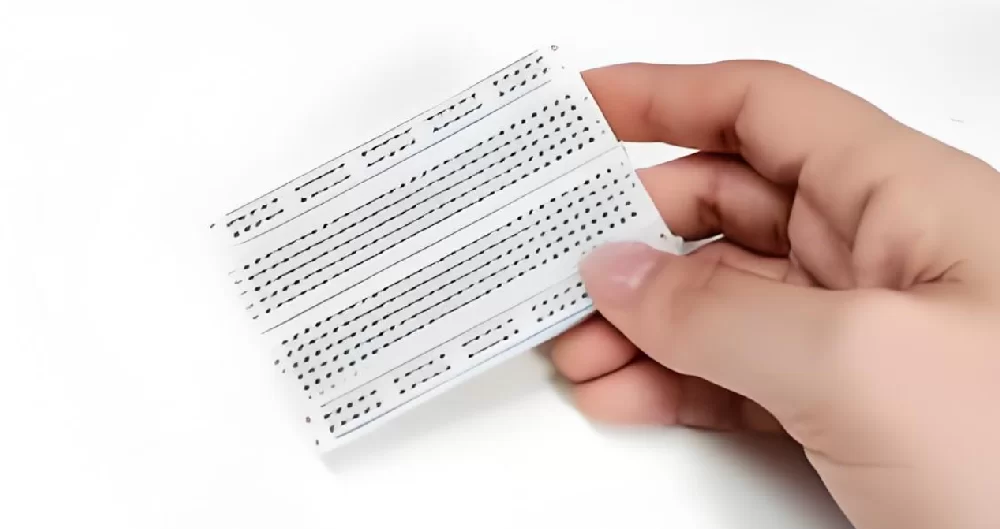

Breadboard circuit

Although Breadboard PCBs are highly useful in electronic prototyping, the final product typically requires a more reliable and compact design. At this point, the results from testing on a Breadboard PCB can be translated into PCB design. By converting a validated Breadboard PCB into a PCB, engineers can ensure the quality and performance of the final product while reducing uncertainties during production. Breadboard PCB usage also underscores the importance of thorough testing in PCB design. While PCB design is more specialized and complex, the testing process on a Breadboard PCB provides valuable data to support the final PCB design. This transition from Breadboard PCB to PCB not only enhances design accuracy but also reduces rework costs caused by design errors.

Breadboard circuit provides a vital link between theoretical circuit design and practical implementation. This bridge allows designers to experiment with different configurations, test various components, and refine their ideas without the immediate commitment to manufacturing a printed circuit board (PCB). This flexibility is particularly valuable in educational settings, where students can gain hands-on experience with real circuits before delving into more complex PCB designs. One of the key advantages of using a Breadboard PCB is its reusability. Unlike soldered PCBs, where components are permanently fixed, breadboards allow for easy changes and adjustments. This characteristic is particularly useful in the early stages of design, where frequent modifications are often necessary. Engineers can swap out components, reroute connections, and test different configurations with minimal effort, leading to a more refined final design.In the context of PCB production, Breadboard PCB testing helps reduce the risk of costly errors.

By thoroughly vetting a design on a breadboard, engineers can identify potential issues that might not be apparent during the theoretical design phase. This preemptive troubleshooting saves time and money in the long run, as it reduces the likelihood of needing multiple PCB revisions.The transition from a Breadboard PCB to a PCB also involves careful consideration of factors such as component placement, trace routing, and thermal management. While breadboards provide a flexible platform for experimentation, PCBs require a more structured approach to ensure reliability and performance. Engineers must translate the flexible, often chaotic layout of a breadboard into a well-organized PCB design that meets all the necessary specifications.

Breadboard circuit prototyping also supports innovation by providing a low-risk environment for experimenting with new ideas. Whether in a startup developing a new consumer gadget or a large company working on cutting-edge technology, breadboards allow teams to quickly iterate on designs and test novel concepts. This iterative approach is crucial in industries where time-to-market is a significant competitive factor. The final transition from Breadboard PCB to PCB is a critical step in bringing a product to market. Once a design has been validated on a breadboard, it can be meticulously translated into a PCB layout that meets industry standards. This process often involves collaboration between designers, engineers, and manufacturers to ensure that the final product is not only functional but also manufacturable at scale.

Breadboard circuit plays a fundamental role in the development of electronic products, bridging the gap between initial design concepts and final production. For instance, virtual breadboarding tools are now available, allowing engineers to simulate and test circuit designs on a computer before moving to physical prototyping. These tools provide an additional layer of convenience and precision, enabling more efficient design workflows. By enabling rapid prototyping, thorough testing, and iterative design