Driver circuit board holds a critical position in modern electronic products. As one of the core components of electronic devices, it is responsible for controlling and driving various electronic elements such as LED displays, motors, and sensors. The quality of the design and production of a Driver PCB directly impacts the performance and stability of the entire device, making it an essential aspect of PCB design and production.

Driver circuit board design first needs to consider the stability and efficiency of the circuit. To ensure that the Driver PCB can operate normally under different working conditions, engineers must conduct detailed simulations and tests of the circuit. This includes selecting components, designing signal transmission paths, and considering thermal management. The complexity of Driver PCB design lies in its need to coordinate multiple signals simultaneously while ensuring these signals remain undisturbed during transmission. These challenges make Driver PCB design a critical area within PCB design.Driver PCB is not just a simple circuit design; it also involves power management, signal regulation, and protection circuit design. The integration of these functions requires engineers to consider the interactions and compatibility between various components during the design phase. To ensure efficient operation, engineers often use multi-layer PCB designs, which not only reduce electromagnetic interference but also effectively distribute power and ground lines, optimizing signal transmission quality.

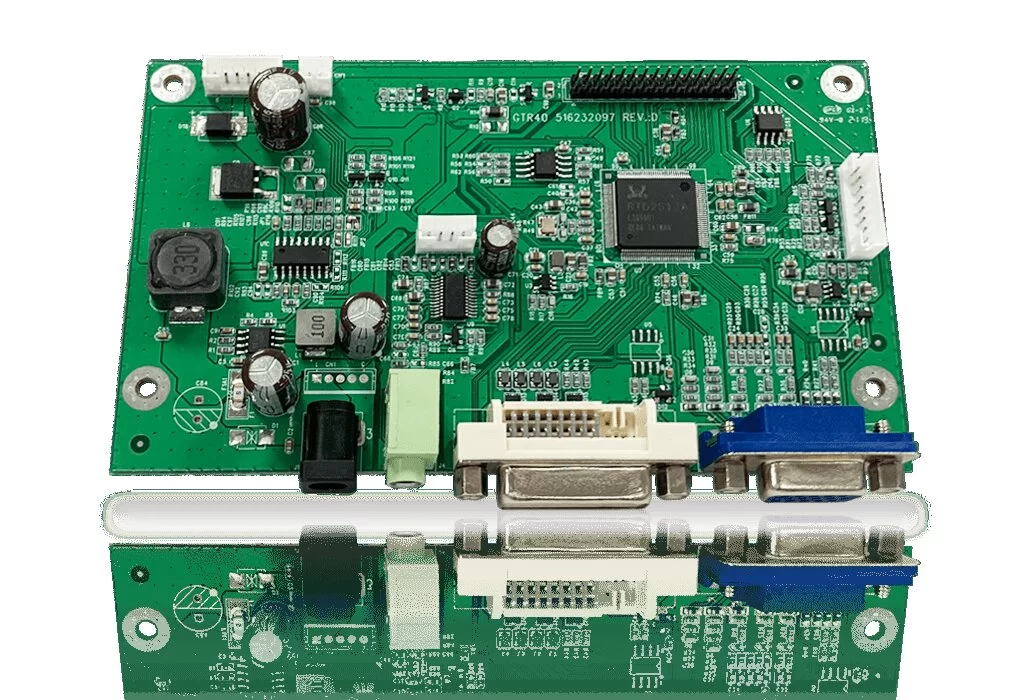

Driver circuit board

Driver PCB production is also a complex process. During manufacturing, precise processes and high-quality materials are crucial factors in ensuring the performance of the Driver PCB. Since these boards often need to handle high current and voltage, stringent quality control measures must be adopted to avoid potential manufacturing defects. Additionally, the production process must address thermal management, particularly in high-power applications, where a well-designed heat dissipation system significantly enhances the reliability and lifespan of the circuit board.

Driver circuit board must endure various environmental conditions in actual applications. Therefore, during design and production, engineers typically conduct rigorous environmental tests, including temperature cycling, vibration, and humidity tests. These tests aim to ensure that the Driver PCB maintains stable performance even under extreme conditions. By passing these tests, the design of the Driver PCB can be further optimized, improving its reliability in practical applications.With the continuous advancement of electronic technology, Driver PCB design and production are also evolving. For example, in fields like smart homes, industrial automation, and electric vehicles, the application of Driver PCBs is becoming increasingly widespread. These areas impose higher requirements on Driver PCBs, demanding higher efficiency, better compatibility, and support for multiple communication protocols to adapt to various complex application scenarios.

Driver circuit board reliability is crucial for the stable operation of the entire device. In the design process, engineers often employ redundancy design and protection circuits to prevent system crashes caused by single-point failures. Additionally, the electromagnetic compatibility design of the Driver PCB is vital. Proper shielding and grounding measures can effectively reduce the impact of electromagnetic interference on the circuit board.Driver PCB optimization in design and high-quality production is key to ensuring stable operation in various applications. During the design phase, engineers need to continuously adjust and optimize circuit parameters and conduct extensive simulations to find the best design solution. In the production phase, precise manufacturing processes and strict quality control are fundamental to ensuring the performance of the Driver PCB.

In conclusion, Driver circuit board is a key component in electronic devices, with its design and production quality directly affecting the performance and lifespan of the entire device. As technology continues to evolve, Driver PCB design and production will face increasing challenges but also provide more opportunities for innovation in electronic products. By continuously optimizing designs and improving manufacturing processes, Driver PCBs will play an increasingly important role in future electronic products.