Low volume PCB fabrication has become a crucial method for meeting small-batch production needs. This approach not only helps companies save costs but also accelerates time-to-market, enhancing market competitiveness. This article will explore the applications of Low-volume PCB manufacturing in PCB design and production, along with the numerous advantages it brings.

Low volume PCB fabrication refers to the production of printed circuit boards in smaller quantities. This method is particularly suitable for prototype design, small-batch production, and customized products. Due to the smaller production quantities, manufacturers can more flexibly adjust production processes and quickly respond to customer demands. Additionally, Low-volume PCB manufacturing can reduce inventory pressure and lower risks.In the PCB design phase, small-batch production helps engineers quickly validate design concepts. When developing new products, engineers often need to iterate designs and tests multiple times. Through low volume fabrication, engineers can quickly receive feedback at each iteration and make adjustments based on test results, thereby shortening the product development cycle. This method not only improves design efficiency but also significantly reduces development costs.

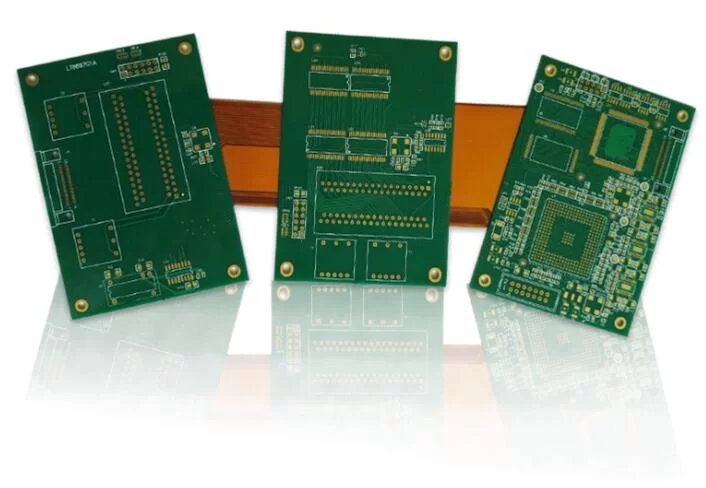

Low volume PCB fabrication

Low volume PCB fabrication employs advanced manufacturing technologies and flexible production line configurations during the production process. For example, automated production equipment and quick-changeover techniques enable production lines to switch between different orders in a short time. Furthermore, high-precision production equipment and quality inspection systems ensure the quality and consistency of each circuit board. Whether it's double-sided boards, multilayer boards, or flexible boards, Low-volume PCB manufacturing can meet various design requirements.small-batch production finds extensive application in practice. Whether in consumer electronics, medical devices, automotive electronics, or industrial control systems, this manufacturing method meets stringent requirements. Its excellent flexibility and efficiency make Low-volume PCB manufacturing the preferred choice across various industries. For instance, in the consumer electronics field, small-batch production needs of smartwatches, wearable devices, and smart home products can be realized through Low-volume PCB manufacturing. In medical devices, Low-volume PCB manufacturing helps R&D teams quickly iterate designs, ensuring product safety and performance.

One of the key features of Low-volume PCB manufacturing is its ability to integrate advanced technologies and manufacturing techniques. This integration ensures that the circuit boards produced are of the highest quality, even in small quantities. Techniques such as laser direct imaging (LDI) and automated optical inspection (AOI) are vital in the production process. LDI allows for precise pattern creation on the circuit board, enhancing its functionality and reducing errors. AOI, meanwhile, ensures that each circuit board meets strict quality standards by detecting any defects or inconsistencies during manufacturing.Additionally, small-batch production incorporates innovative thermal management solutions. Effective thermal management is crucial for maintaining the performance and longevity of electronic components. The circuit boards use advanced materials and design strategies to dissipate heat efficiently, preventing overheating and ensuring stable operation. This is particularly important in high-performance applications such as data centers, telecommunications, and industrial automation, where reliable thermal management can significantly enhance system performance and reliability.

Low volume PCB fabrication will continue to drive the development of the electronics industry. With the rise of the Internet of Things (IoT), artificial intelligence (AI), and other new technologies, the demand for small-batch, diversified circuit boards is increasing. Low-volume PCB manufacturing, with its excellent flexibility and efficiency, is set to play a significant role in these emerging fields. Moreover, as manufacturing processes advance and new materials are continuously applied, the performance and application range of Low-volume PCB manufacturing will further expand.

Another significant advantage of small-batch production is its compatibility with various assembly processes. This compatibility allows manufacturers to integrate the circuit boards into their existing production lines without substantial modifications. For example, the circuit boards can be assembled using surface mount technology (SMT), through-hole technology (THT), or a combination of both. This flexibility in assembly methods enables manufacturers to choose the most suitable process based on their specific requirements and constraints.

Low volume PCB fabrication, as an essential method in PCB design and production, is continuously transforming the electronics industry. By enhancing the flexibility, efficiency, and cost-effectiveness of manufacturing, this approach not only meets the current small-batch production needs of electronic products but also provides a solid foundation for future technological developments.