Cleaning corrosion is a crucial step in the design and production process of PCBs (Printed Circuit Boards). Corrosion can not only affect the performance of a PCB but also shorten its lifespan. Therefore, the step of clean up corrosion is indispensable in manufacturing and maintenance. This article will delve into the importance of clean up corrosion, common methods, and specific operations in practical applications.

PCB corrosion is one of the most common phenomena we observe in our daily lives. For example, the surface of an iron object is sometimes covered with some orange or reddish brown. The formation of this layer is caused by a chemical process called rusting, which is a form of PCB corrosion. PCB corrosion is a decay process caused by a chemical reaction between a material and its environment. The reaction usually occurs in the form of oxidation. Corrosion occurs when the exposed surface of the metal comes into contact with a gas or liquid. And this process is related to the temperature, acid, salt, etc. of the exposed environment.

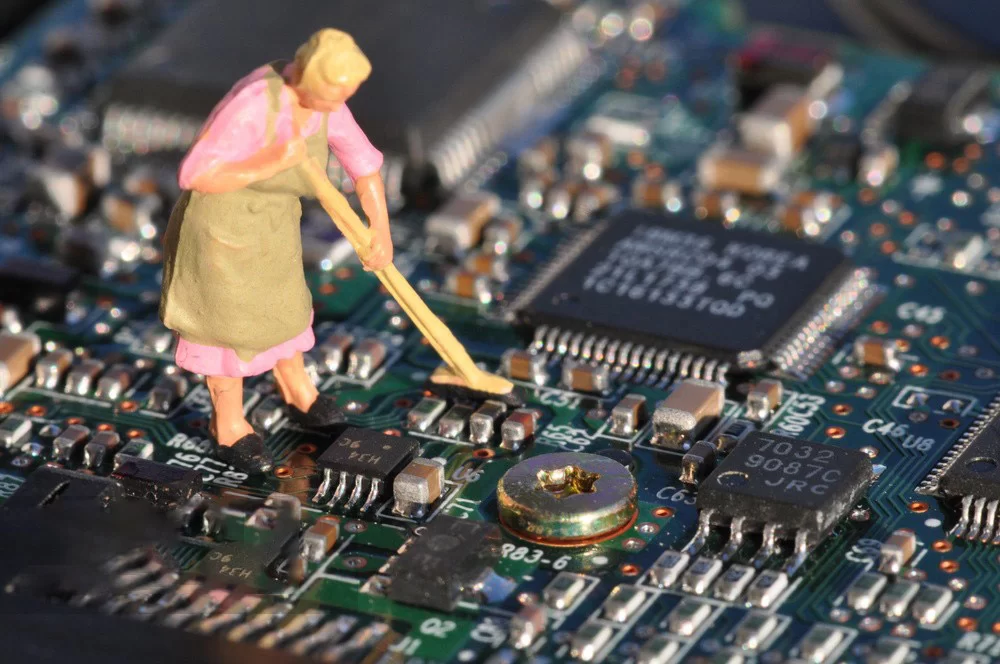

Cleaning corrosion

Cleaning corrosion is essential for ensuring the normal operation of a PCB. Corrosion is typically caused by moisture, chemicals, and electrochemical reactions. These factors lead to the oxidation or corrosion of the metal layers on the PCB surface, thereby affecting the circuit's conductivity and stability. If corrosion is not cleaned in time, the performance of the PCB will gradually decline, eventually leading to the failure of the entire circuit.To effectively clean up corrosion, a combination of chemical and physical cleaning methods is usually employed. Chemical cleaning generally uses acidic or alkaline solutions to dissolve and remove corrosion products. This method is efficient, but it is crucial to carefully select and use chemical cleaners to avoid secondary damage to the PCB. Physical cleaning includes methods such as brushing and sandblasting, which are mainly used to remove stubborn corrosion and oxide layers.

The process of cleaning corrosion needs to be strictly controlled and monitored. First, a thorough inspection of the PCB should be conducted to determine the extent and scope of corrosion. Then, suitable cleaning methods and cleaners should be selected based on the specific situation. During cleaning, it is important to maintain a dry and clean environment to prevent recontamination. Finally, after cleaning, the PCB should be dried and treated with protective measures to ensure that no chemical residues or moisture remain on its surface.

For corrosion issues that arise during production, clean up corrosion is equally critical. During the manufacturing of PCBs, the raw materials used, processing techniques, and environmental conditions can all contribute to corrosion. For example, during electroplating and etching processes, improper operations or insufficient process control can easily cause corrosion of the metal layers. Timely cleaning of corrosion in such cases can prevent the production of defective products, thereby improving production efficiency and product quality.

Cleaning corrosion helps extend the lifespan of PCBs. Corrosion can not only lead to a decline in electrical performance but also reduce the mechanical strength of the PCB, increasing the risk of fractures and damage. Regular inspection and cleaning of corrosion can effectively slow down the aging process of PCBs, extend their service life, and reduce maintenance and replacement costs.clean up corrosion plays a vital role in PCB design and production. It is not only related to the performance and quality of the product but also directly impacts production efficiency and cost control. In practical applications, by choosing appropriate cleaning methods and cleaners and strictly controlling the cleaning process, corrosion issues can be effectively resolved, ensuring the stability and reliability of PCBs.

Overall, Cleaning corrosion is a key step in PCB design and production. Through scientific management and operations, the impact of corrosion on PCBs can be minimized, ensuring their efficient and stable operation. In the future of electronic manufacturing, clean up corrosion will continue to play an important role, providing strong support for improving product quality and extending service life.