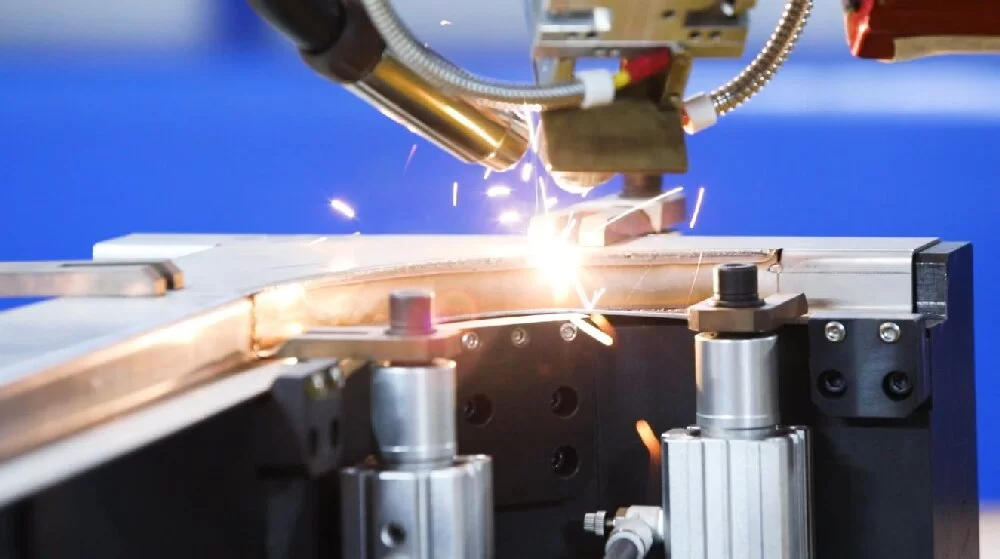

Laser solder is a joining process using a focused laser beam, which is used in many industrial fields due to its high precision. The welding energy is generated by a high-power laser. In robotic applications, the high-energy laser beam is usually transmitted to the processing position through a flexible optical fiber. Here, the laser power is focused to a small focal spot with the help of a processing head. The resulting high energy density will melt the workpiece and weld the parts.

The working principle of laser solder is based on the high energy density of the laser beam. The laser beam concentrates the light energy on the welding point through a focusing system, causing the material to melt quickly and form a strong weld. Compared with traditional welding methods, laser welding has unparalleled advantages, such as fast welding speed, small heat-affected zone, and high welding quality. This process has the advantages of deep melting, fast speed, small deformation, low requirements for welding environment, high power density, no influence of magnetic field, not limited to conductive materials, no vacuum working conditions, and no X-rays during welding. It is widely used in the field of high-end precision manufacturing. Therefore, laser welding is widely used in high-precision applications in various industries such as automotive, aerospace and medical. Therefore, this process has been widely used in the design and production of PCBs.

Laser solder

Laser solder plays an increasingly important role in the manufacture of modern electronic products. As electronic products continue to develop towards miniaturization and high density, traditional welding methods can no longer meet the production requirements of high precision and high efficiency. The application of this process is particularly extensive in all aspects of PCB production. First of all, laser welding can be used for precision welding of components. With the increase in the complexity and density of electronic products, the size of components is getting smaller and smaller, and traditional welding methods are difficult to meet the requirements of high-precision welding. Laser welding can ensure the accuracy and reliability of welding by precisely controlling the energy and position of the laser beam.

In addition, laser solder can also be used for the connection of multi-layer PCBs. Multi-layer PCBs are widely used in modern electronic products, with complex internal structures, and electrical connections between layers need to be made through metal holes. Traditional welding methods are difficult to complete such precise connections without damaging the PCB, while laser welding can avoid damage to the PCB through non-contact operation while ensuring the firmness of the connection.

In practical applications, the advantages of this process are not only reflected in accuracy and speed, but also in production efficiency and cost. Since laser welding can be automated, it greatly improves production efficiency and reduces labor costs. At the same time, the high precision and high reliability of laser welding reduce the product rework rate and improve the quality and stability of the product.

The application of laser solder in PCB design and production has greatly improved the level of electronic manufacturing. Its high precision, non-contact operation and high efficiency make it an indispensable part of modern electronic product manufacturing. With the continuous advancement of technology, laser welding will show its unique advantages in more fields and bring more possibilities to electronic manufacturing. Laser welding has become an important technology in modern electronic manufacturing. Its wide application in PCB design and production not only improves production efficiency and product quality, but also promotes the development of electronic products towards miniaturization and high density. In the future, with the continuous advancement of this welding technology, it will show its strong potential in more fields and bring more innovat