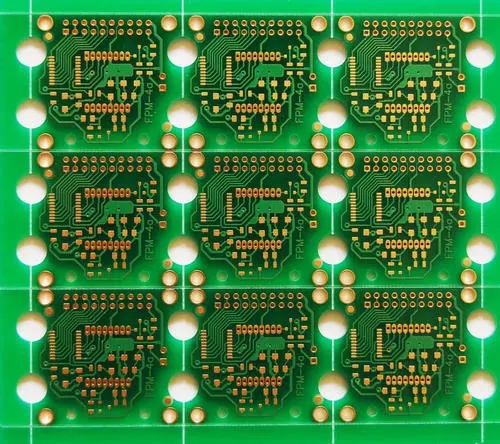

The substrate used in PCB board

Taking ordinary double-sided panels as an example, the sheet materials generally include FR-4, FR-1, CEM-1, CEM-3, etc., and the thickness of the sheet ranges from 0.2mm to 3.0mm

The thickness of copper varies from 0.5 ounces to 6 ounces, all of which have caused a huge price difference in the sheet material;

The difference of the suppliers makes the sheet of uniform specifications have a price difference of tens of yuan per square meter; even the same sheet supplier is divided into several

Species. In addition, inks, character inks, etc., so the difference in materials has resulted in a variety of prices.

Second, the production costs of different PCB surface treatments are also very different

Different surface treatments will cause different costs. Such as gold-plated PCB and tin-sprayed PCB board, making shape gongs and die punches,

The use of silk-screened lines and dry film lines will result in different costs, resulting in diversification of prices.

Third, the price of PCB is different due to different difficulty

The difficulty of PCB itself will also cause different costs. If you want to look at the circuit on the PCB, such as the density of the wire is thin (in the

4/4mm) or less, the price will be calculated separately; whether there is a BGA bit, etc. There are 1000 holes on both circuit boards, one board hole

If the diameter is greater than 0.6mm and the hole diameter of the other board is less than 0.6mm, different drilling costs will be formed; for example, the two types of circuit boards

They are the same, but the line width and line spacing are different, one is greater than 0.2mm, and the other is less than 0.2mm, which will also cause different production

Cost, because the difficult board scrap rate is higher, the cost will inevitably increase, which will cause the price diversity.

Fourth, different customer requirements will also cause different prices

The level of customer requirements will directly affect the yield of the board factory. For example, a board according to IPC-A-600E, class1 requires 98%

The pass rate, but according to the requirements of class3, it may only have a pass rate of 90%, which results in different costs for the board factory, and finally leads to the product

The price changes.

Five, the price diversity caused by different PCB manufacturers

Even for the same product, because different manufacturers have different process equipment and technical levels, different costs will be generated.

Many manufacturers like to produce gold-plated plates because of the simple process and low cost. However, some manufacturers also produce gold-plated plates.

Waste increases, resulting in higher costs, so they prefer to produce tin-sprayed panels, so their quotation for tin-sprayed panels is better than that of gold-plated panels.

Low.

Six, price differences caused by different payment methods

At present, PCB board manufacturers generally adjust PCB prices according to different payment methods, ranging from 5% to 10%.

Become a price difference.

7. Different regions cause price diversity

At present, in terms of geographical location in China, the price is increasing from south to north, and there are certain differences in prices in different regions, so

Different regions also cause the diversity of prices. How to calculate PCB quotation!

1. Plate cost (different plate cost is different)

2. Drilling costs (the number of holes and the size of the aperture affect the drilling costs)

3. Process cost (different process requirements of the board lead to different process difficulties, and even prices will vary)

4. Artificial water and electricity plus management costs (this cost depends on the cost control of each factory, relatively speaking, Taiwan-funded factories are much lower

country)