About the difference between PCB and PCBA and the future development trend

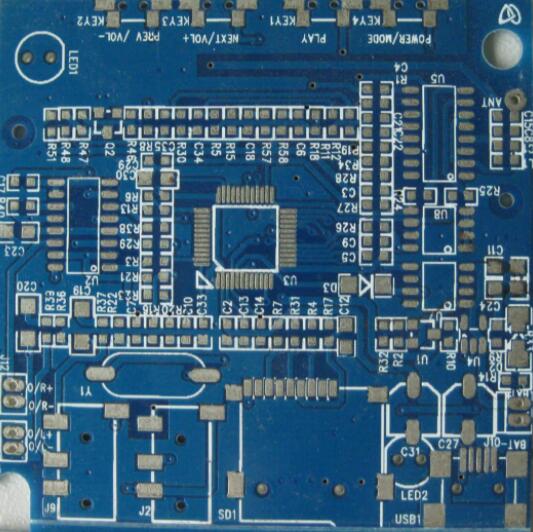

PCB is what we call circuit board circuit board, and the PCB drawing is processed into circuit board circuit board called PCB. After SMT (mounting) on the empty PCB board, the components required for the board are pasted, called PCBA. The board with the components already pasted, only needs to assemble the shell, debug the program, and a complete electronic product is completed.

According to the survey, many small and medium-sized electronic product manufacturers have to contact the patch manufacturers after purchasing PCBs. More and more electronic product manufacturers will choose to allow PCB manufacturers to process patches at the same time as PCBs, or to allow patch manufacturers to purchase PCBs instead. In these two modes, electronic product manufacturers can directly assemble and use the circuit boards they have to produce finished products. Many manufacturers that can only produce PCB, unconditionally process PCBA on behalf of them, will lose customers who need to be processed at the same time. Such customers choose manufacturers who have the ability to add at the same time, or choose a placement factory to let the placement factory purchase PCB on its behalf. Many people may ask why the patch factory can purchase PCB, and why the PCB factory does not contact the patch factory. It is a very simple matter for SMT manufacturers to purchase PCBs. They only need to ask customers to provide production drawings and production processes. Moreover, the PCB market price is very transparent and easy to purchase. However, PCB manufacturers do not understand the products and prices of various components. It is difficult to contact the patch factory for patch production, and only focus on the production of PCBs.

Since 2009, PCB manufacturers have gradually expanded their factories and increased PCBA generation processing lines while producing PCBs. This one-step approach has been recognized by many electronic product manufacturers. This method of contemporary processing has both advantages and disadvantages. OEM manufacturers are increasing their profit margins, but at the same time their risks are also increasing. The main reason is that each electronic product needs different components to purchase components for customers. Even if the same product has different design drawings, the components used are different. If the type of components purchased is wrong, the board and components will be scrapped at the same time. It is also difficult to estimate the direct economic losses. The increase in manpower and material resources is also inevitable. Under the pressure of market competition, simultaneous processing of PCB and PCBA is also inevitable. At present, the country has higher and higher requirements for environmental protection and greater efforts in link governance. This is a challenge but also an opportunity for PCB factories. If PCB factories are determined to solve the problem of environmental pollution, then FPC flexible circuit board products can be at the forefront of the market, and PCB factories can get opportunities for further development.

The Internet era has broken the traditional marketing model, and a large number of resources have been gathered together to the greatest extent through the Internet, which has also accelerated the development speed of FPC flexible circuit boards, and then as the development speed accelerates, environmental problems will continue to appear in PCB factories. In front of him. However, with the development of the Internet, environmental protection and environmental informatization have also been developed by leaps and bounds. Environmental information data centers and green electronic procurement are gradually being applied to the actual production and operation fields.