What is the SMT "red glue" process? In fact, the correct name should be the SMT "dispensing" process. Because most of the glue is red, it is commonly called "red glue". In fact, there are also yellow glues. "Solder mask" is the same as "green paint". It can be found that there is a red glue like object in the middle of the small parts of resistors and capacitors. This is red glue. It was originally designed to stick the parts on the circuit board, and then the circuit board can pass through the waves. The wave soldering furnace allows parts to be tinned and joined to the solder pads on the circuit board without falling into the hot wave soldering furnace.

The red glue process was developed because there were still many electronic components that could not be transferred from the original plug-in (DIP) package to the surface mount (SMD) package immediately. Imagine a circuit board has half DIP parts and the other half is SMD parts. How do you place these parts so that they can all be automatically soldered to the board? The general practice is to design all DIP and SMD parts on the same side of the PCB board. SMD parts are printed with solder paste and soldered in the reflow furnace, while the remaining DIP parts are exposed on the other side of the circuit board because all solder feet are exposed.So you can use the wave soldering furnace process to solder all the DIP solder feet at one time.

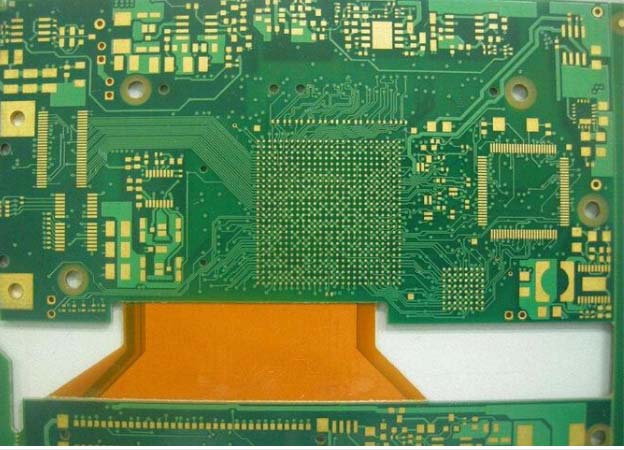

Later, a clever engineer thought of a way to save space on the circuit board, that is, to find a way to put parts on the side that originally only had DIP parts feet and no parts, but most DIP parts have too many gaps in the body, or The part material cannot withstand the high temperature of the soldering furnace, so it cannot be placed on the side of the soldering furnace. However, the general SMD parts have been designed to withstand the Reflow temperature, even if they are immersed in the wave soldering furnace for a short period of time. There will be no problem, but there is no way for SMD to pass through the wave soldering furnace for printing solder paste, because the temperature of the soldering furnace must be higher than the melting point of the solder paste, so the SMD parts will fall into the soldering tank due to the melting of the solder paste Inside.

Of course, some engineers later thought of using thermosetting glue to adhere SMD parts. This glue needs to be heated to cure. It just happens to be able to use a Reflow furnace to solve the problem of parts falling out of the tin bath. Red glue was born., So the size of the circuit board has been further reduced.

Application of red glue process in SMT

1.Cost saving

One of the advantages of using SMT red glue process is that when wave soldering, there is no need to make fixtures, thus reducing the cost of making fixtures. Therefore, some of the small batch order customers in order to save costs, usually require PCBA processors to use the red glue process. However, as a relatively backward soldering process, PCBA processors are usually reluctant to adopt the red glue process. This is because the red glue process needs to meet the specific conditions to be used, and the welding quality is not as good as solder paste welding process.

2.Larger component size. Wide spacing

In the wave soldering, generally choose the side of the surface-mounted components over the crest, while the side of the plug-in is above. If the surface mounted component size is too small. Spacing is too narrow, then in the wave crest on the tin, will cause the solder paste connected, resulting in a short circuit. Therefore, when using the red glue process, it is necessary to ensure that the component size is large enough, the spacing should not be too small.

The difference between SMT solder paste and red glue process

1.Process angle

When using the dispensing process, the red glue in the case of more points will become the bottleneck of the entire SMT patch processing line; and when using the printed glue process, the requirements of the first AI after the patch, and the position of the printed glue is very high precision requirements. In contrast, the solder paste process requires the use of the furnace bracket.

2. Quality perspective

Red glue for cylindrical or glass body encapsulated parts are easy to drop, and under the influence of storage conditions, red glue board is more susceptible to moisture, which leads to drop. In addition, compared to solder paste, red rubber boards have a higher defect rate after wave soldering, and typical problems include solder leakage.

3. Manufacturing Costs

The over-oven bracket in the solder paste process is a larger investment, and the solder on the solder joints is more expensive than solder paste. In contrast, glue is a cost specific to the red glue process.

The choice between using the red glue process or the solder paste process is generally based on the following principles:

When more SMT components and plug-in components less, many SMT chip makers usually use solder paste process, plug-in components are used after processing soldering;

When more plug-in components and fewer SMD components, the general use of red glue process, plug-in components, the same use of post-processing welding. Whichever process is used, the purpose is to improve yield. However, in contrast, the solder paste process has a lower defect rate, but also a relatively low yield.

In the hybrid process of SMT and DIP, in order to avoid single-sided reflow once . Wave once the second over the furnace situation, in the wave soldering side of the PCB chip component waist dotted with red glue, which can be over the wave soldering on a tin, eliminating the need for solder paste printing process.

In addition, red glue generally play a fixed and auxiliary role, while the solder paste is really play a role in welding. Red glue does not conduct electricity, while the solder paste conducts electricity. In terms of the temperature of the reflow soldering machine, the temperature of the red glue is relatively low, and also requires wave soldering to complete the soldering, while the temperature of the solder paste is relatively high.

Often, the use of the red glue process depends on the actual production requirements, e.g. certain components need to be fixed before reflow soldering to prevent displacement or for the fixing of through-hole plug-in components in mixed-technology assemblies.