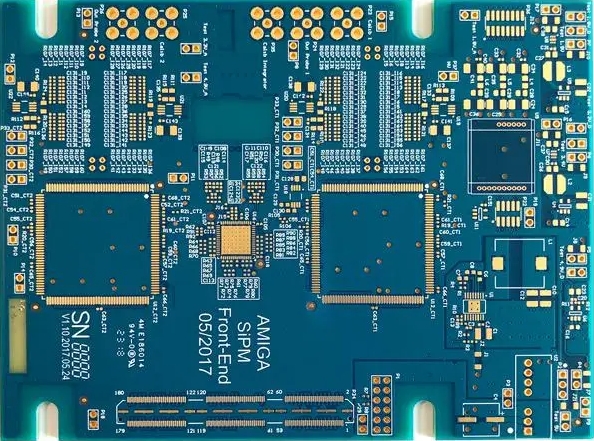

In the highly competitive electronics manufacturing industry, SMT PCB (Surface Mount Technology Printed Circuit Board) design is not only a reflection of technical prowess, but also a key factor in determining product performance, reliability and cost. In order to stand out in the competition, designers must follow a series of design principles to ensure that the board's high efficiency, high reliability and high quality.

1.Functionality Priority and Compact Design

In SMT PCB design, functionality is the first principle. At the beginning of the design, it is necessary to clarify the functional requirements of the circuit, and according to the needs of the components for a reasonable grouping and layout. At the same time, the compactness of the design is also a factor that can not be ignored. Under the premise of meeting functional requirements, the PCB area should be minimized to reduce material costs and improve production efficiency.

The layout design should follow the following principles:

Functionality Priority: According to the functional requirements of the circuit, components are reasonably grouped, and the flow of signals and interference factors are considered.

Compactness: minimize PCB area and reduce material costs without affecting functionality.

Maintainability: easy to test and repair, leaving enough space between components to avoid mutual interference.

2.Component selection and layout

Component selection and layout directly affect the performance and reliability of the SMT PCB. In the selection of components, should take into account its performance, package form, cost and other factors. In the layout, the following principles should be followed:

Components with the same function should be placed as close as possible to reduce signal transmission distance and interference.

High-heat components should be kept away from other sensitive components to reduce thermal interference.

The layout should try to avoid resonance and mechanical stress to improve product reliability.

3.Cabling design principles

Wiring design is a key part of SMT PCB design, reasonable wiring can reduce signal interference and improve circuit performance. Wiring design should follow the following principles:

Minimize the length of the wire: try to shorten the length of the wire to reduce signal attenuation and interference.

Avoid cross-interference: a certain distance should be maintained between different signal lines to avoid cross-interference.

Consider power and ground wires: power and ground wires should be as wide as possible to reduce resistance and inductance and improve the reliability of the circuit.

4.Soldering point design and welding quality assurance

Soldering point is another important part of the SMT PCB design. The design quality of the soldering point directly affects the quality and reliability of the product soldering. In the soldering point design, should follow the pad design moderate, reasonable spacing between the soldering point, consider the soldering process and other principles. By optimizing the design of the soldering point, the strength and reliability of the soldering point can be ensured, and the overall performance of the product can be improved.

5. Thermal design and heat dissipation principles

As the performance of electronic products continue to improve, the heat dissipation problem is more and more prominent. In the SMT PCB design, should give full consideration to thermal design and heat dissipation to improve product stability and reliability. Thermal design and heat dissipation should follow the following principles:

Reasonable planning of heat dissipation channels: in PCB design, should be reasonable planning of heat dissipation channels to ensure that the heat can be emitted in a timely manner.

Use materials with good heat dissipation performance: Where conditions permit, try to use materials with good heat dissipation performance, such as metal substrates.

Consider the thermal performance of components: In the selection process, the thermal performance of pcb components should be fully considered, and prioritize the selection of components with good thermal performance.

SMT PCB design is a complex and delicate process that requires comprehensive consideration of multiple factors. By following the above design principles, we can achieve efficient, reliable and optimized PCB design, laying a solid foundation for the performance improvement and cost reduction of electronic products.