Panasonic R-5775 MEGTRON6 (M6) is an ultra-low loss, high heat resistant circuit board material.

MEGTRON6 includes MEGTRON 6 (N), MEGTRON 6 (G), MEGTRON6 (K), and MEGTRON 6. Low dielectric constant (Dk) glass cloth laminated plate-5775 (N)/prepreg R-5670 (N), standard E glass cloth laminated plate-5775/prepreg R-5670.

M6(N) vs M6

MEGTRON6 (M6) is a commonly used glass fiber reinforced epoxy resin substrate. This material has good mechanical, electrical, and heat resistance properties, making it very suitable for the manufacturing of mobile, network, and wireless products that require high-speed, ultra-low loss circuit materials.

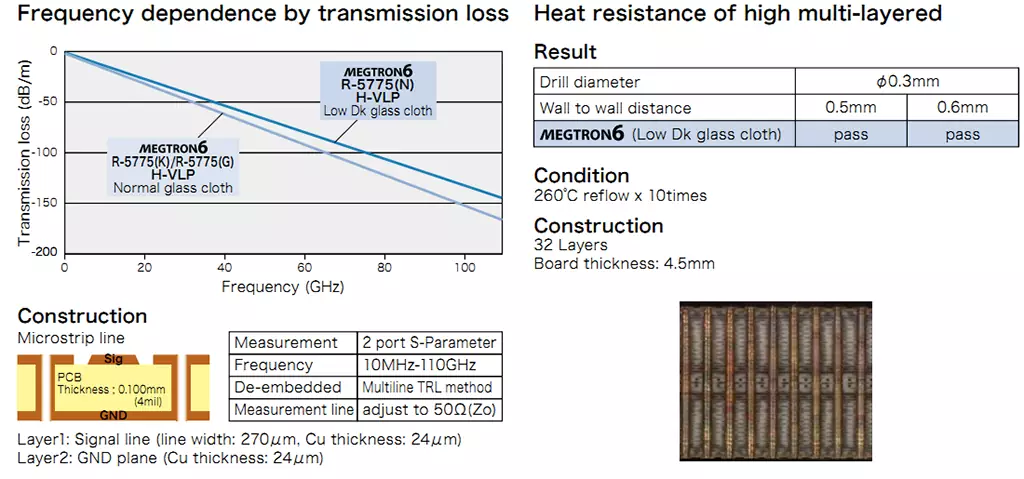

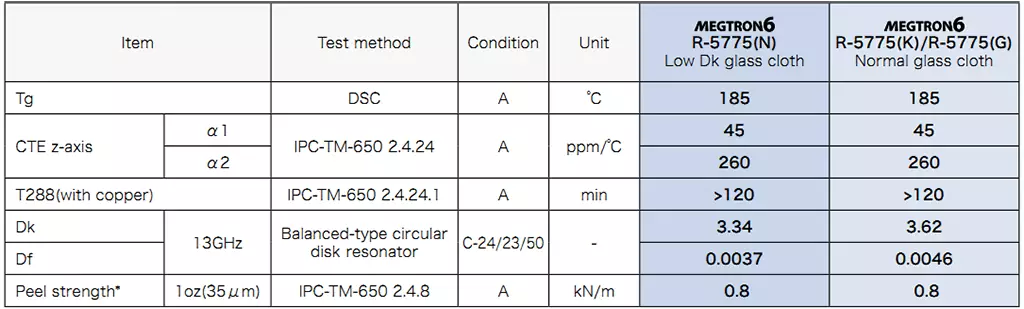

MEGTRON6 R-5775 uses polyphenylene ether (PPE) resin as the matrix resin, which has good low dielectric constant and low dielectric loss tangent (Dk=3.34, Df=0.002 at 1GHz). Simultaneously using high-frequency ultra-low profile copper foil (H-VLP), the material's transmission loss is close to that of PTFE resin.

The processing requirements of MEGTRON6 R-5775 are similar to those of traditional FR-4 sheets, and do not require special pre-treatment for through-hole copper plating (PTFE sheets require plasma treatment) or other pre-treatment processes. The solder mask process can also be ground.

The Z-axis CTE of MEGTRON6 R-5775 is 45ppm/℃, which makes the circuit board have good stability in electroplating through holes. MEGTRON6 has a high thermal decomposition temperature (TG185) and is compatible with lead-free soldering installation requirements. It has excellent physical and mechanical properties, heat resistance, and electrical insulation, low moisture absorption, high strength, and good dimensional stability.

In the field of high-speed circuit design, the requirements for accuracy and performance are becoming increasingly stringent. The development of Panasonic M6 circuit board materials, especially for R-5775 (N) and R-5670 (N) materials, has brought new opportunities for the design and prototyping of high-speed circuit boards. These materials not only support more complex designs, but also ensure stable transmission characteristics at high frequencies.

By using M6, the PCB design team can achieve more compact and high-performance circuit layouts. Its advantages include:

1. Improved signal integrity: The low dielectric constant of R-5775 (N) and R-5670 (N) materials helps reduce signal propagation delay and improve overall circuit performance.

2. Improved design flexibility: The ultra-high multi-layer circuit board design supports more complex circuit integration, allowing designers to achieve more functions in a smaller space.

3. Accelerated product launch time: Panasonic M6 technology simplifies the design and sampling process, shortening the time from concept to physical prototype.

MEGTRON6 Datasheet

For the sampling process of ultra-high multi-layer circuit boards, R-5775 (N) and R-5670 (N) materials also demonstrate their efficiency. These materials not only improve manufacturing yield, but also accelerate the entire sampling cycle by reducing repetitive design iterations. In addition, due to the excellent processing characteristics of M6 material, MEGTRON6 can also maintain high performance standards in mass production, providing higher quality and reliability for end products.

By combining the precise control of M6 and the characteristics of R-5775 (N)&R-5670 (N), the design and sampling of ultra-high multi-layer high-speed circuit boards have been able to maintain a leading position at the forefront of technology. This is a significant advancement not only for circuit board manufacturers, but also for companies that need to use these high-speed boards in high-performance computing, high-speed communication, and precision electronic devices.

Panasonic M6 technology and its application in R-5775 (N)&R-5670 (N) have provided unprecedented efficiency and performance for the design and prototyping of ultra-high, multi-layer, and high-speed circuit board. With the continuous pursuit of speed and complexity in the electronics industry, this technology combination has laid a solid foundation for future innovation.