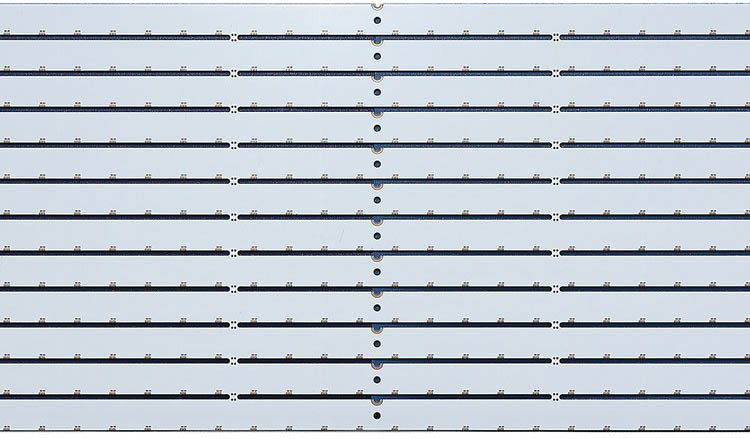

Light LED PCBA

PCB layers: 1-2layers

Substrate: FR-4, Aluminum, Copper

Surface treatment: HASL lead-free / OSP

Solder resist: White

Copper thickness: 0.5oz-2oz

Silk Screen Color: Black

PCB Testing: Yes

PCBA Testing: Yes

Application: PCB LED Lighting Assembly

iPCB specializes in Light PCB assembly

1. Light PCB's SMT can be soldered and bonded, processed with incoming materials, and can be OEM and SMT stencils.

2. Light PCB assembly, post-soldering, plug-in, testing, production, etc.

3. Can provide relevant Light PCB product ideas and documents, and our company will develop and design, develop and customize one-stop PCB LED Lighting assembly.

4. The price of led PCB assembly is reasonable, proofing, samples, small batches, and large batches are available.

5, led Light circuit board assembly price concessions, quality assurance, delivery on time.

6. Welcome new and old customers to consult Light PCB assembly.

Light PCB assembly uses FR4 material, aluminum base material, copper base material.

The LED light with a relatively wide distribution of LED lamp beads is a PCB circuit board made of FR4 material, and various grades are better than the CAM-3 material used before! LED light PCB boards with higher requirements often use aluminum substrates.

Light PCB assembly

Light PCB circuit board of aluminum base material

Aluminum-based light PCB is a metal-based light PCB circuit board with a good heat dissipation function. Generally, a single-sided light PCB board consists of a three-layer structure, which are a circuit layer, an insulating layer, and a metal base layer.

Aluminum-based light PCBs are also designed for use with 2-layer aluminum-based PCBs, with a structure of circuit layer, an insulating layer, an aluminum base, an insulating layer, and the circuit layer. Very few applications are multilayer light PCBs.

Aluminum-based light PCB assembly can be divided into tin-sprayed aluminum-based light PCB, anti-alumina-based light PCB, silver-plated aluminum-based light PCB, immersion gold aluminum-based light PCB, etc.;

According to the use, it can be divided into street light aluminum-based light PCB, fluorescent light aluminum-based light PCB, LB aluminum-based light PCB, COB aluminum-based light PCB, package aluminum-based light PCB, bulb aluminum-based light PCB, power aluminum-based light PCB, Automotive aluminum-based light PCB, etc.

The surface of the power device is mounted on the aluminum-based light PCB circuit layer. The heat generated by the device is quickly conducted to the metal aluminum base layer through the insulating layer, and then the heat is transferred out by the metal base layer, so as to realize the heat dissipation of the aluminum-based PCB to the device. Compared with the traditional FR-4 circuit board, the aluminum substrate can reduce the thermal resistance to a very low level, so the aluminum substrate has excellent thermal conductivity; compared with the thick-film ceramic circuit, its mechanical properties are extremely excellent.

In addition, aluminum-based PCB has the following unique advantages: it meets the requirements of RoHS and is more suitable for the surface mount of the SMT process. With the promotion and promotion of energy-saving lamps, various energy-saving and gorgeous LED lamps are very popular in the market, and the aluminum-based light PCB assembly used in LED lamps has also begun to be applied on a large scale.

Copper-based light PCB assembly

The heat dissipation effect of copper-based led light circuit board assembly is better, so copper-based light PCB assembly is usually used in automotive LED headlights.

iPCB specializes in Light PCB Assembly, We can provide relevant Light PCB product ideas and documents, and our company will develop and design, develop and customize one-stop PCB LED Lighting assembly.

Light LED PCBA

PCB layers: 1-2layers

Substrate: FR-4, Aluminum, Copper

Surface treatment: HASL lead-free / OSP

Solder resist: White

Copper thickness: 0.5oz-2oz

Silk Screen Color: Black

PCB Testing: Yes

PCBA Testing: Yes

Application: PCB LED Lighting Assembly

For PCB technical problems, iPCB knowledgeable support team is here to help you with every step. You can also request PCB quotation here. Please contact E-mail sales@ipcb.com

We will respond very quickly.