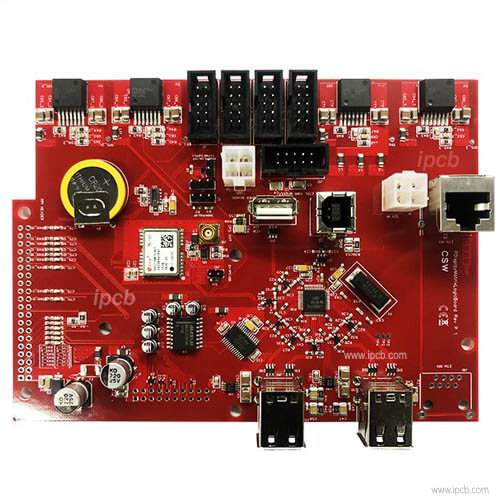

Network pcba production for data transmission

Layers : 6Layers

Surface Process : Immersion Gold

Gold thickness : 2U

PCB Color : Red solder mask

PCB Testing : Yes

PCBA Testing : Yes

Provide PCB production: Yes

iPcb company provide full electronic components.

PCBA Testing : Yes ( Customer provide testing step with video )

RoHS compliant lead-free assembly

PCBA production is to process an empty PCB board through one process, and finally process it into a PCBA electronic product for users. In the process of production, there are links. Any quality problem in any link has a great impact on the quality of products.

1. PCBA processing single surface assembly process: solder paste printing - patch - reflow welding;

2. PCBA processing double-sided surface assembly process: printing solder paste on side a - patch - reflow soldering - turnover - printing solder paste on side B - patch - reflow soldering;

3. PCBA processing single side mixed loading (SMD and thc are on the same side): solder paste printing - patch - reflow soldering - Manual plug-in (THC) - wave soldering;

4. Single side mixed packaging (SMD and thc are on both sides of PCB): printing red glue on side B - patch - red glue curing - turnover - plug-in on side a - wave soldering on side B;

5. Double sided mixing device (THC on side a, SMD on both sides a and b): printing solder paste on side a - patch - reflow welding - turnover - printing red glue on side B - patch - red glue curing - turnover - plug-in on side a - wave soldering on side B;

6. Mixed packaging on both sides (SMD and THC on both sides of a and b): printing solder paste on side a - patch - reflow welding - turnover - printing red glue on side B - patch - red glue curing - turnover - plug-in on side a - wave soldering on side B - plug-in on side B is attached.

Network PCBA production

With the increasingly fierce competition in the electronic industry, the share of the sales market is divided by many well-known electronic brands, and other electronic manufacturers can only compete for the remaining resources. Therefore, how to quickly produce products and put them into the market has become the core problem to be solved. Many enterprises can only focus on design, marketing and after-sales service for their own interests, and can only outsource the production and assembly of products. ipcb provides a complete set of supporting services for companies with such product assembly needs. Regardless of product batch size or product category, ipcb conducts software configuration and final testing according to technical specifications.

PCBA electronic product assembly and processing refers to the electronic processing manufacturer to undertake the processing project of the electronic client, and conduct the semi-finished and finished product assembly of electronic products. The difference between the two is mainly whether the products received by the entrusting party can be used directly. Electronic product assembly and processing is very popular in developed countries and other places, which completely saves the electronic R & D companies in the factory rent, equipment purchase to spend a lot of money, save production costs, improve product profitability. More and more manufacturers with long-term vision and the ability to grasp the market prospect will join it. However, there is a premise that the consignor needs to ensure that the processing party has sufficient capacity and experience to ensure the correct production and normal delivery of products, so as to seize the market opportunities.

iPCB Circuits Limited(ipcb®.com) professional provides a variety of electronic processing services, such as PCBA production, PCBA processing test, SMT chip, dip plug-in and finished product assembly, aging test, etc. Equipped with professional international standards of the factory for production, through the U.S. UL certification, ISO9001 production standards, finished product pass rate as high as 99.8%. 10 years of processing experience and the trust of many listed companies are worthy of your favor. The developed countries are keen on electronic processing. Quality is the premise standard, advanced equipment and rich processing experience is the basis. Ipcb has more than 4000 cooperative customers all over the world, which is a witness to our ability.

Network pcba production for data transmission

Layers : 6Layers

Surface Process : Immersion Gold

Gold thickness : 2U

PCB Color : Red solder mask

PCB Testing : Yes

PCBA Testing : Yes

Provide PCB production: Yes

iPcb company provide full electronic components.

PCBA Testing : Yes ( Customer provide testing step with video )

RoHS compliant lead-free assembly

For PCB technical problems, iPCB knowledgeable support team is here to help you with every step. You can also request PCB quotation here. Please contact E-mail sales@ipcb.com

We will respond very quickly.