What are the specific requirements for the production of high-frequency PCB circuit boards?

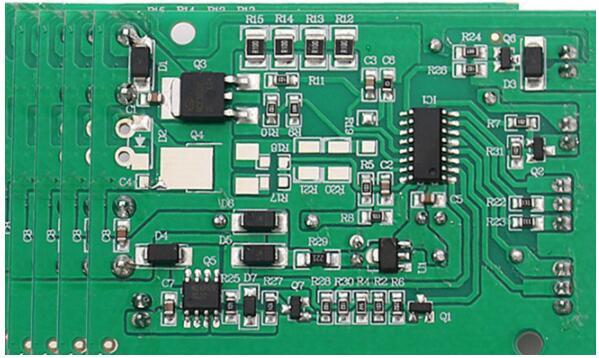

The high frequency board refers to the special circuit board with higher electromagnetic frequency. Generally speaking, the high frequency can be defined as the frequency above 1GHz. High-frequency PCB circuit boards have a wide range of applications, and there are strict requirements in terms of design and manufacturing. So, what are the specific requirements for the production of high-frequency PCB circuit boards?

1. The corner of the transmission line should be 45° to reduce the return loss;

2. Adopt high-performance dielectric circuit boards whose dielectric constant values are strictly controlled according to the number of layers. This method is conducive to effective simulation calculation of the electromagnetic field between the insulating material and the adjacent wiring.

3. Produce in accordance with PCB design specifications related to high-precision etching. It is stipulated that the total line width error is +/-0.0007 inches. The overall management of wiring (wire) geometry and coating surface is very important to solve the skin effect problem related to microwave frequency and realize these specifications.

4. In a high frequency environment, it is best to use surface mount SMD components, and avoid using components with leads.

5. For signal vias, avoid using the via processing (pth) process on sensitive boards, because this process will cause lead inductance at the vias; buried blind holes or back drills should be used.

6. It is necessary to provide a rich grounding layer to prevent the influence of the three-dimensional electromagnetic field on the circuit board.

7. To choose electroless nickel plating or immersion gold plating process, do not use HASL method for electroplating; this kind of electroplating can provide better skin effect for high-frequency current and help reduce environmental pollution.

8. The solder mask can prevent the flow of solder paste. Generally, a solder dam is used as the solder mask.

The above are some specific requirements for high-frequency PCB circuit board production introduced by PCB engineers. I believe it will be helpful to you. iPCB is a high-tech manufacturing enterprise focusing on the development and production of high-precision PCBs. iPCB is happy to be your business partner. Our business goal is to become the most professional prototyping PCB manufacturer in the world. Mainly focus on microwave high frequency PCB, high frequency mixed pressure, ultra-high multi-layer IC testing, from 1+ to 6+ HDI, Anylayer HDI, IC Substrate, IC test board, rigid flexible PCB, ordinary multi-layer FR4 PCB, etc. Products are widely used in industry 4.0, communications, industrial control, digital, power, computers, automobiles, medical, aerospace, instrumentation, Internet of Things and other fields.