As the circuit design of PCB circuit board becomes more and more complex and the circuit density becomes higher and higher, the gold finger is also developed from simple finger graphics to various strange shapes (such as finger shape, circle, square, and even local circuit needs to be plated with gold finger consumer line). In the traditional gold finger electroplating, the anti electroplating blue adhesive paper is wrapped manually to maintain the non electroplating area. Manual blue coated offset paper restricts the consumption of gold finger electroplating due to the difficulty of worker training (generally 1-2 months) and slow speed, which is difficult to meet the strange graphics; Some Taiwan PCB circuit board factories adopt the method of manually opening the skylight, which can improve the speed of wrapping blue glue, but because manual operation is easy to scratch green oil and graphics, wrapping green glue paper is added after manually opening the skylight, which greatly improves the cost, and the control is difficult to meet the requirements of high-grade boards.

When the output of the golden finger board is large, the golden finger consumption line can take a variety of ways (such as increasing the voltage, increasing the gold concentration, and increasing the temperature of the liquid medicine tank) to increase the output, and the blue coated adhesive tape station must borrow a small number of unskilled workers from the external process for consumption. The consumption rate of these unskilled workers is very low, the quality of the blue coated adhesive tape is worrying, and the scrapping of PCB circuit boards also follows;

When the output of gold finger board increases, a small number of skilled workers have nothing to do; The consumption ability of blue coated adhesive tape of different models of gold finger board varies greatly (from 1 piece / min to 1 piece / 8-10 minutes). PPC must consider the consumption time of blue coated adhesive tape of different models of gold finger board when arranging the consumption plan; The consumption of special-shaped gold finger board is time-consuming, laborious and material consuming (green adhesive tape needs to be wrapped manually), and the quality is still difficult to guarantee; The consumption plan arrangement of golden finger electroplating workshop has been changed again and again due to the reason of wrapping adhesive tape, and the completion rate of consumption plan is also very low. The tape wrapping station has become the bottleneck restricting the smooth stop of gold finger electroplating scheme and consumption, which restricts and controls the consumption rhythm and output rate of gold finger electroplating workshop This paper analyzes the process consumption ability of detailed examples to find out the bottleneck station restricting gold finger electroplating and improvement methods.

Gold finger electroplating consumption process:

Take up the board - cut the board edge / Gong copper sheet - manually wrap the blue adhesive tape - manually wrap the green adhesive tape (optional) - press the adhesive tape - nickel plated gold - tear the adhesive tape - wash the board - reflect.

Analysis of consumption ability of gold finger electroplating stations:

Bottleneck station analysis

If the monthly order is 120000 ft2, due to the uneven distribution of orders, the daily consumption of the scheme fluctuates between 2000 ft2 and 6000 ft2. When the load is 6000 ft2 / day, it can be seen from the consumption ability / load analysis that the manual blue glue and gold-plated fingers are the bottleneck stations, which will form the backlog of products and the delay of consumption scheme, Even the 24-hour consumption of hand wrapped blue glue can not meet the requirements, and the necessary meal / shift handover time must be deducted for manual operation, and the 12-hour consumption of workers is not ideal. According to the investigation of foremen and workers, the gold-plated fingers slow down the consumption rate because of the insufficient supply of blue coated glue. When the supply of blue coated glue is sufficient, the nickel gold consumption rate can be increased by 20%, and the consumption can meet the requirements of the consumption plan So the blue glue station is the real bottleneck station. If we want the scheme and consumption to stop smoothly and the consumption logistics to move smoothly, we must take improvement measures to break the bottleneck

Analysis of improvement methods

A. Add 5 persons / shift;

When production declines (e.g. 2000 ft2), workers have nothing to do

B. 4000 ft2 per day;

Too idealized, PPC cannot be arranged

C. Usually 10 people / shift, 15 people / shift when the output is large;

The veteran's efficiency is too low, only 30-50% of the standard output, and little assistance

D. Tl04-07 automatic blue coating glue machine is adopted;

Large investment, waste 4-6 workers / shift, waste 20% of blue glue cost and 70% of green glue cost

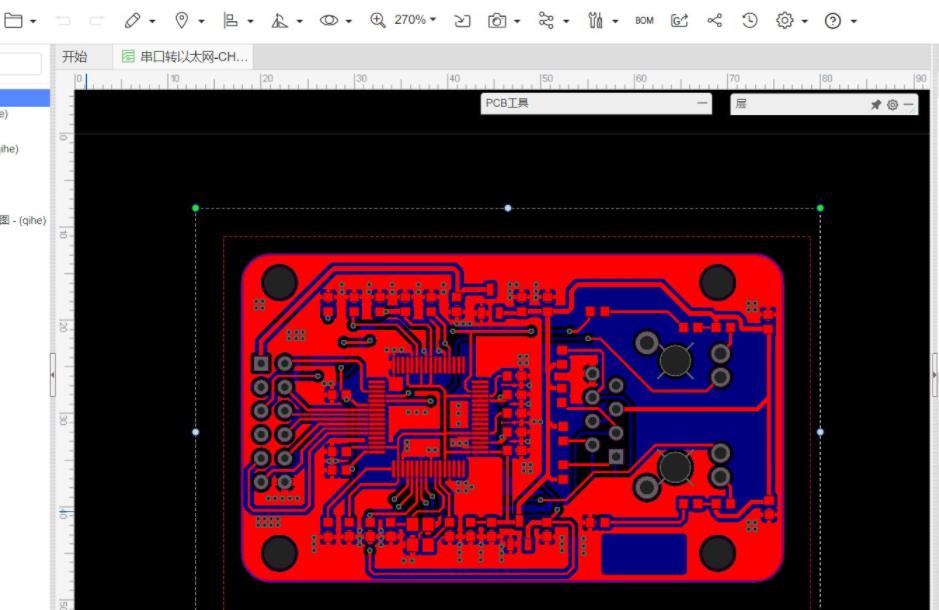

Tl04-07 automatic blue gluing machine using PCB circuit board design CAM Technology

Cam is the abbreviation of computer aided manufacturing, which refers to the use of computers to stop commodity manufacturing. There are narrow sense cam and broad sense cam. In the narrow sense, cam refers to the application of computer to assist in the completion of all manufacturing processes from raw materials to commodities, including indirect manufacturing process and direct manufacturing process. Generalized cam refers to the use of computers in a certain link of the manufacturing process. In computer aided design and manufacturing (CAD / CAM), it usually refers to computer aided machining. More specifically, it refers to NC machining. Its output information is the process path and process content of parts, The input information is the motion path (tool position file) and NC sequence during tool machining.

The 21st century is a period of rapid development and wide application of information technology, and advanced manufacturing technology has become the guarantee for the development of manufacturing industry. CAM technology originated in developed countries in the 1960s, and the development of CAM technology is always closely related to CAD technology, because CAM technology directly uses CAD data information to realize NC programming. Nowadays, CAM technology has become the core foundation of advanced manufacturing industry, and its development and application has become an important symbol to measure the progress of an enterprise and industrial modernization.

Before the popularization of CAM technology, programmers can only determine whether their programming is safe and effective through manual programming and field operation. Programmers need to go through various steps such as part drawing analysis, process scheme, numerical calculation, compiling program sheet to program verification to complete programming. Manual programming can only be used when the part shape is simple and the machining program is short. Once the parts with complex shape, such as parts with non-circular curve, list curve and combined surface, or parts with complex shape and long machining program, the programmer's work efficiency will become lower in the process of manual programming, and compared with automatic programming, it is easy to make mistakes, Even a plane collision will occur, causing immeasurable losses.

With the rapid development of modern industry, CAM technology has been widely used in aircraft, automobile, machinery manufacturing, household appliances and electronic products manufacturing. Especially with the higher and higher precision requirements and more complex shapes of parts in the automotive and aerospace industries, the traditional design and manufacturing methods can not meet the current requirements. At this time, NC milling becomes more and more important. Before NC milling, the application of CAM technology has become an indispensable link.

Add excessive iron filings into the waste liquid containing copper, control the solution temperature to 30-50 degree Celsius, and react for about 1 hour. After the reaction is over, take out the iron filings, filter, wash and dry the replaced copper to obtain metal copper powder, with a purity of more than 99%.

Recovery of copper from copper waste liquid containing chelating agent.

In the waste liquid containing copper, the pH value should be adjusted to more than 11, and the calcium hydroxide exceeding the copper ion amount will be added. Meanwhile, the solution will be stirred to form copper hydroxide precipitation, filtration, washing and precipitation. Add excess sulfuric acid to the precipitation, and then evaporate and crystallize. Take out the crystal and dry it to obtain copper sulfate crystal.

Therefore, the application of CAM technology can avoid many limitations of manual programming, which are embodied in the following points:

(1) As the functions of the existing CAM software are quite mature, the work of NC programming is greatly simplified, and the requirements for the technical background and creativity of programmers are greatly reduced, creating favorable conditions for the popularization of this technology.

(2) Because CAM software is a system software formed with the help of computer's accurate calculation, high-capacity storage and data processing capabilities, as well as rich graphics and text conversion functions, programmers can use its processing simulation function to avoid major safety accidents, so it is worth believing in programming safety.

(3) After so many years of supplement, CAM software will come with dozens of general cutting methods, such as contour machining, surround machining, projection machining, cycloid machining, NURBS non rational sample condition interpolation and milling, which are easy to learn, understand and use flexibly.

(4) In the process of NC milling, the basic cutting condition equation is pre established in the cam software. According to the parameters measured by the measurement system and the working condition of the machine tool, the feed rate, cutting force, cutting speed, cutting operation sequence and coolant flow are adjusted to ensure the machining efficiency and accuracy under the condition of ensuring the surface finish and machining accuracy of parts Tool wear and energy consumption are optimized.

Using computer-aided manufacturing of parts and components can improve the adaptability to product design and variety variation, improve the processing speed and production automation level, shorten the processing preparation time, reduce the production cost, and improve the product quality and labor productivity of mass production. The application of CAM technology provides a strong guarantee for the trial production at the initial stage of iPCB project. In the future, we will more actively explore the wider and deeper application of CAM technology in combination with the needs of the project, so as to provide customers with faster and higher quality services.