The first step is to adjust the contrast and brightness of the canvas in PHOTOSHOP, so that the part with copper film and the part without copper film have a strong contrast, and then turn the second image into black and white, and check whether the lines are clear. If not, repeat This step. If it is clear, save the picture as black and white BMP format files TOP1.BMP and BOT1.BMP.

The second step is to convert the two BMP format files to PROTEL format files, and transfer them into two layers in PROTEL. If the positions of the PAD and VIA on the two layers basically coincide, it indicates that the previous steps are well done. If there is Deviation, repeat the previous step.

The third step is to convert TOP1.BMP and BOT1.BMP into TOP1.PCB and BOT1.PCB respectively, pay attention to the conversion to the SILK layer, which is the yellow layer, and then trace on the TOP and BOT layers, and according to the scan Place the device on the drawing and delete the SILK layer after drawing.

The fourth step is to import TOP1.PCB and BOT1.PCB in PROTEL and combine them into one picture.

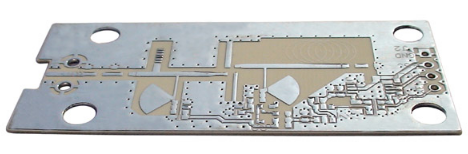

The fifth step is to use a laser printer to print the TOP LAYER and BOTTOM LAYER on the transparent film (1:1 ratio), put the film on the PCB, and compare whether there are errors. If they are correct, the top layer is completed. And the copy board on the bottom.

(3) Inner copy board

1. Scan the inner layer

The surface layer of the circuit board was rubbed off with coarse sandpaper to show that the inner layer came out. The silk screen and green oil were wiped off. The copper wire and copper skin should be wiped a few more times. The copper skin and copper wire should be leaked. After cleaning, put it in the scanner and start PHOTOSHOP, Scan the TOP LAYER and BOTTOM LAYER layers separately in color.

2. Draw the inner PCB board

The first step is to adjust the contrast and brightness of the canvas in PHOTOSHOP, so that the part with copper film and the part without copper film have a strong contrast, and then turn the second image into black and white, and check whether the lines are clear. If not, repeat This step. If it is clear, save the picture as black and white BMP format files TOP2.BMP and BOT2.BMP.

The second step is to convert the two BMP format files to PROTEL format files, and transfer them into two layers in PROTEL. If the positions of the PAD and VIA on the two layers basically coincide, it indicates that the previous steps are well done. If there is Deviation, repeat the previous step.

The third step is to convert TOP2.BMP and BOT2.BMP to TOP2.PCB and BOT2.PCB respectively. Pay attention to the conversion to the SILK layer, which is the yellow layer, and then trace the lines on the TOP layer and the BOT layer. Place the device on the drawing, and delete the SILK layer after drawing.

The fourth step is to import TOP2.PCB and BOT2.PCB in PROTEL and combine them into one picture.

The fifth step is to use a laser printer to print the TOP LAYER and BOTTOM LAYER on transparent film (1:1 ratio), put the film on the PCB, and compare whether there is any error. If it is correct, it is completed. Layer of copy board. Four) Synthetic four-layer board

The copied surface layer pictures and inner layer pictures are combined into a PCB file diagram, and the copying of the four-layer computer motherboard is completed. Then export the PCB file diagram from the copy board software. You can enter the later stage of the board production and component welding to complete the complete cloning of the circuit board.