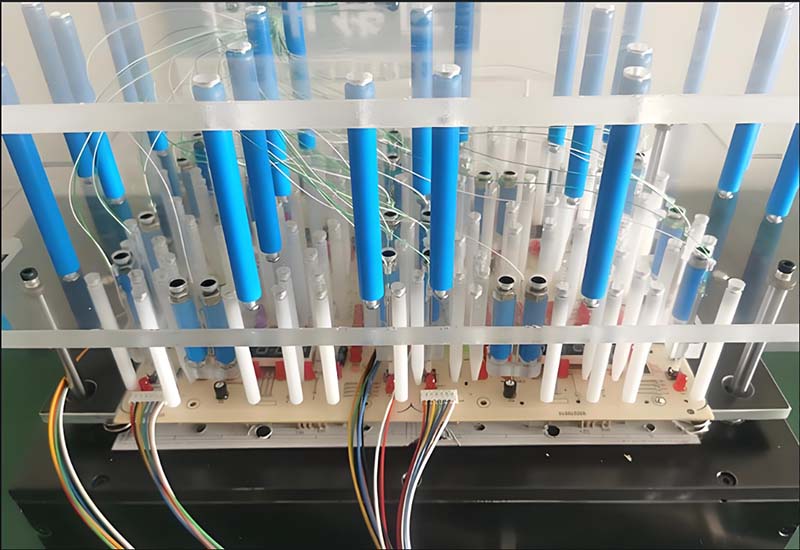

The needle bed is also called ICT test fixture, which is online inspection and test fixture. It is a non-standard test auxiliary fixture that uses electrical performance to test online components to check manufacturing defects and component defects.

The PCB patch processing plant pointed out that it is mainly used to check the online single components and the open, short circuit, and welding conditions of each circuit network. It has the characteristics of simple operation, fast and rapid, and accurate fault location.The needle bed(ICT test fixture) can be simulated Device function and digital device logic function test, fault coverage rate is high, a special needle bed needs to be made for each kind of single board, this needle bed is called ICT test fixture in industrial production.

Bed of needle(ICT test fixture) component category can detect component value error, fault or damage,memory class programme error,etc..In the process category can be found in the welding short circuit, component insertion errors, reverse insertion,missing mounting, pin warping, virtual welding, PCB short circuit,broken wires and other faults.Test faults are directly localised to specific components, device pins and network points,with accurate fault location.Maintenance faults do not require much expertise.Program-controlled automated tests are simple to operate and fast to test.Single board test times are typically a few seconds to tens of seconds.

To remove dust from the scale,it should be cleaned with anhydrous ethanol.When cleaning, rotating gloves (dipped in a small amount of anhydrous ethanol) should be used to gently clean the grating in one direction, do not scrub back and forth with force (so as not to scratch the grating). It is also required that the air source for the test fixture should be dry,filtered of oil and water,and then enter the equipment,otherwise it will affect the service life of the equipment and the measurement accuracy.

ICT can effectively detect various defects and faults in the SMT assembly process,but it cannot evaluate the clock performance of the entire circuit board system. Functional testing can test whether the entire system can meet the design objectives. It takes the unit under test on the circuit board as a functional unit,provides it with input signals, and detects the output signals according to the design requirements of the functional unit.

ICT test fixtures are widely used in the electric power field,ICT test fixture is an acronym for in-circuit test fixture.It is a standard test equipment used to test the electrical performance and electrical connections of in-line components to check for manufacturing defects and defective parts.

Needle bed test PCB circuit board:

However,with the evolution of technology,PCB size has become smaller and smaller. It is already a bit difficult to squeeze so many electronic parts on a small circuit board.Therefore,the problem of test points occupying circuit board space is often on the design side.There is a tug-of-war with the manufacturing side, but this topic will be discussed later when there is a chance.The appearance of the test point is usually round,because the probe is also round,which is easier to produce,and it is easier to get the adjacent probes closer, so that the needle density of the needle bed can be increased:

1.The use of a needle bed for circuit testing has some inherent limitations on the mechanism.For example,the minimum diameter of the probe has a certain limit, and the needle with too small diameter is easy to break and damage.

2.The distance between the needles is also limited,because each needle must come out of a hole,and the back end of each needle must be soldered with a flat cable. If the adjacent holes are too small, except for the gap between the needles There is the problem of contact short circuit,and the interference of the flat cable is also a big problem.

3.Needles cannot be implanted next to some tall parts. If the probe is too close to the high part, there is a risk of collision with the high part and cause damage. In addition, because of the high part, it is usually necessary to make holes in the needle bed of the test fixture to avoid it, which indirectly makes it impossible to implant the needle. Test points for all parts that are increasingly difficult to accommodate on the circuit board.

4.As the boards are getting smaller and smaller,the number of test points has been repeatedly discussed. Now there are some methods to reduce test points, such as Net test, Test Jet, Boundary Scan, JTAG. . Etc.; there are other test methods that want to replace the original needle bed test,such as AOI, X-Ray, but it seems that each test cannot replace ICT 100%.

Regarding the ability of ICT to implant needles,you should ask the matching PCB test fixture manufacturer,that is,the minimum diameter of the test point and the minimum distance between adjacent test points. There is usually a desired minimum value and a minimum value that the ability can achieve.Large-scale manufacturers will require that the distance between the minimum test point and the minimum test point cannot exceed a few points, otherwise the jig will be easily damaged.

Difference between flying probe test and needle bed test?

Flying probe test and bed of needle test are both a kind of contact test, and flying probe test is an improved and upgraded version of in-line bed of nails test.

In the actual PCBA chip processing online needle bed test for different products need to make different special fixed needle bed fixtures, so as to achieve the same time, sequential test of all test points for rapid testing. Online test speed is faster, suitable for electronic OEM processing of large quantities of a single species of test. However, due to the needle bed fixture needs to be individually customised and production time is long, complex programming, the price is also higher, in electronic processing also needs to be strictly in accordance with the industry standard grid spacing arrangement, in the face of today's high-density, high-precision circuitry components, on-line needle bed test sometimes appear blind, so there is an improved version of the flying probe test.

Flying probe test is through the use of movable probe instead of a fixed needle bed fixture, while increasing the probe drive device,the specific PCBA processing test procedures can be directly from the circuit board CAD software, such a structure can make the test capability in terms of accuracy,minimum test gap and other aspects of the ability to get a substantial increase.But the flying probe test speed is still not as fast as the online needle bed test,so PCBA processing plant in the actual processing of flying probe test are generally used in multi-species, small batch electronic online test and prototype verification above.