Some simple common rules for circuit boards!

How to use a miniature PCB coil as an inductive sensing element?

Click the red letter above to see

Combustion performance, also known as flame retardancy, self-extinguishing, fire resistance, fire resistance, flammability, etc., is the main indicator for evaluating the anti-combustion performance of materials.

Ignite the flammable material sample with a flame that meets the requirements, and extinguish the flame within the specified time. According to the degree of combustion of the sample, it is divided into three levels, divided into three levels, FH1, FH2, FH3, etc., and placed it vertically as vertical Placed in three levels: FV0, FV1, VF2, etc.

Solid PCB boards can be divided into HB boards and V0 boards.

Highly flame-retardant steel plates are mostly used for single-sided steel plates,

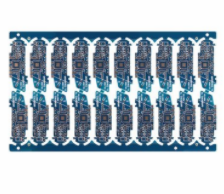

Highly flame-retardant VO boards are mostly used for double-layer boards and multilayer boards.

This type of PCB board meets the requirements of V-1 fire rating and can be made into FR-4 board.

The circuit board must be flame-resistant, cannot burn at a certain temperature, but can only be softened. This point is called the glass transition temperature (Tg point), and it is related to the dimensional stability of the PCB board.

What are the advantages of high TgPCB circuit boards? How to use high TgPCB?

When the temperature rises to a certain range, the substrate of the high Tg printing plate will change from "glass state" to "rubber state", and the temperature at this time is called the glass transition temperature (Tg) of the plate. That is to say, Tg is the highest temperature at which the substrate remains rigid.

What are the specific models of the circuit board?

Divide as follows according to the level from low to high:

-94VO-22F-CEM-1-CEM-3-FR-4.

The details are as follows:

: Ordinary cardboard, not fire-resistant (low-grade materials, molded holes, can not be used as power boards

:Fireproof cardboard (die punch

:Single side half glass fiber board (mold

:Single-sided fiberglass board (must be punched with a computer, not a die

Double-sided semi-glass fiber board (except for double-sided cardboard, it is the lowest grade material for double-sided boards, simple).

Double-layer boards can also be used, which is 5~10 yuan/m2 cheaper than FR-4 version

: Double-sided fiberglass board.

The circuit board must be flame-resistant, cannot burn at a certain temperature, but can only be softened. This point is called the glass transition temperature (Tg point), and it is related to the dimensional stability of the PCB board.

The advantages of high TgPCB circuit boards and high TgPCB high Tg printed boards when the temperature rises to a certain range, the substrate will change from "glass state" to "rubber state".

The temperature at this time is called the glass transition temperature (Tg). That is to say, Tg is the highest temperature (°C) at which the substrate maintains rigidity. In other words, ordinary PCB substrates will not only soften, deform, melt and other phenomena at high temperatures, but also show a sharp decline in mechanical and electrical properties (I think everyone will not want to see the classification of PCB boards and see their own products. ).

The thickness of ordinary thin plates is above 130 degrees, the thickness of high thin plates is above 170 degrees, and the thickness of medium thin plates is about 150 degrees.

Printed circuit boards usually have a temperature of Tg ≥ 170°C and are called high Tg printed circuit boards.

The heat resistance, moisture resistance, chemical resistance, stability and other properties of the printed board have been significantly improved, and have been significantly improved. The greater the thermal weight, the better the temperature resistance of the board, especially in the lead-free production process, there are more applications of high thermal weight.

High heat refers to high heat resistance. In the electronic industry represented by computers, with the rapid development of electronic technology, people are increasingly inclined to functionalization and multi-levelization, and the high heat resistance of PCB substrate materials is an important guarantee for its development. With the emergence and development of high-density mounting technologies represented by SMT and CMT, PCBs are increasingly inseparable from the support of high-heat-resistant substrates in terms of small aperture, thinning, and thinning.

Therefore, the difference between ordinary FR-4 and high TgFR-4 is that they are in a hot state, especially after moisture absorption.

During heat treatment, the material's mechanical strength, dimensional stability, adhesion, water absorption, thermal cracking, expansion properties and other aspects are different. High-density products are significantly better than ordinary PCB substrates.

In recent years, the number of customers requiring the production of high-standard printed boards has increased year by year.

With the development and advancement of electronic technology, new requirements have been put forward for the base materials of printed boards, thereby promoting the continuous development of copper clad laminate standards. The main standards of the base material are as follows:

2. National standard At present, China's classification standard for substrate material PCB board is

-47221992 and GB4723-4725-1992 are the copper clad laminate standards in Taiwan, China. They are CNS standards based on the Japanese JIs standard and were released in 1983.

(2) Other national standards mainly include: Japanese JIS standard, American ASTM, NEMA, MIL, IPc, ANSI, UL, British Bs, German DIN, VDE, French NFC, UTE, Canadian CSA, Australia AS, former Soviet Union FOCT, international IEC, etc. .

Suppliers of original PCB design materials, commonly used and commonly used are: Building\Building\International, etc.

Receiving documents: protelautocadpowerpcborcadgerber or solid cardboard, etc.

.Board type: CEM-1, CEM-3FR4, materials with high TG;

Maximum board size:

Processing board thickness: 0.4mm-4.0mm (15.75mm-157.5mm

Maximum number of processing layers: 16 layers.

Thickness of copper foil layer:

Finished board thickness tolerance: +/-0.1mm (4mm

·Molded size tolerance: computer milling: 0.15mm (6mil) molded sheet:

Minimum line width/interval: 0.1mm (4mil) line width control capacity:

The minimum drilling diameter of the finished product: 0.25 mm (10 mm

The minimum punching diameter of the part: 0.9 mm (35 mm

Final aperture error:

Unsaturated fatty acid content:

Finished hole wall copper thickness: 18-25um (0.71-0.99 mm

Minimum SMT patch spacing:

Surface coating: chemical precipitation agent, tin spray, nickel plating (water/soft gold), silk screen glue, etc.

Solder mask thickness: 10-30μ

Peeling resistance:

The hardness of the solder mask: >5H.

Weld resistance welding capacity: 0.3-0.8 mm

Media constant: ε=2.1-10.0.

·Insulation resistance: 10KΩ-20MΩ.

Characteristic impedance: 60ohm±

Temperature influence: The temperature is 288°C, and the temperature is 10°C.

Warpage of finished board:

·Product usage: communication equipment, automotive electronics, instrumentation, GPS, computer, MP4, power supply, household appliances, etc.

According to the types of PCB reinforcement materials, it is usually divided into the following categories:

First, phenolic PCB paperboard.

Because this type of PCB is composed of paper pulp and wood pulp, it sometimes becomes cardboard, V0 board, flame-retardant board and 94HB, etc. Its main material is wood pulp fiber paper, which is made into PCB board after being pressurized by phenolic resin.

This type of cardboard has the characteristics of being non-fire resistant and perforating processing, low cost, low price, and low density. The phenolic paper substrates we often see are XPC, FR-1, FR-2, FE-3, etc. And 94V0 belongs to flame-retardant paperboard, which can be fireproof.

The second is the composite PCB substrate.

This type of material is also made into powder board, with wood pulp paper or cotton pulp paper as the reinforcement material, and glass fiber cloth as the surface reinforcement material. These two materials are made of flame-retardant epoxy resin. Among them are single-sided half-glass fiber 22F, CEM-1, double-sided half-glass fiber board CEM-3, etc., of which CEM-1 and CEM-3 are the most commonly used composite base copper clad laminates.

Three, glass fiber PCB substrate.

Sometimes it becomes epoxy board, glass fiber board, FR4, fiber board, etc. It uses epoxy resin as adhesive and glass fiber cloth as reinforcement. This type of board has a higher working temperature and a suitable environment.