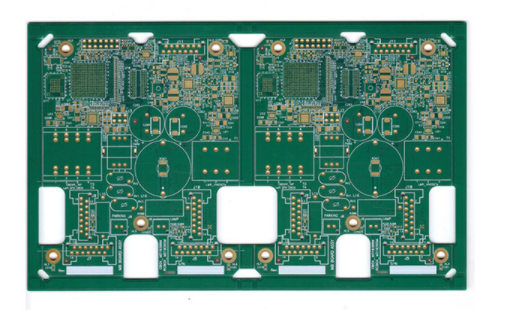

Thick copper circuit board technology

Preparation and electroplating treatment of thick copper circuit boards before electroplating. The main purpose of thick copper plating is to ensure that there is enough thick copper plating in the hole to ensure that the resistance value is within the range of process requirements. As a plug-in, it is fixed in place to ensure the connection strength; as a surface-encapsulated device, some holes are only used as vias to conduct electricity on both sides.

Test items. Mainly check the metallization quality status of the hole to ensure that there are no extra objects, burrs, black holes, holes, etc. In the hole; check whether there are dirt and other unwanted objects on the surface of the substrate; check the serial number, drawing number, process file and process description of the substrate; find out the installation location, installation requirements and the plating area that the plating tank can withstand; plating area And the process parameters must be clear to ensure the stability and feasibility of the electroplating process parameters; prepare the conductive parts for cleaning, first turn on the electricity to make the solution in an activated state; determine whether the bath composition is qualified and the surface area of the electrode plate; if the spherical anode is installed on the column, The consumption must also be checked. Check the firmness of the contact parts and the fluctuation range of voltage and current.

The circuit board factory, the multilayer circuit board factory, and the Shenzhen circuit board factory remind you of the quality control of thick copper circuit boards. Accurately calculate the plating area and refer to the impact of the actual production process on the current, correctly determine the required current value, grasp the current changes during the electroplating process, and ensure the stability of the electroplating process parameters; test plating with a debug board before plating thick copper circuit boards to make The plating solution is in an active state; determine the direction of the total current flow, and then determine the order of hanging the board. In principle, it is adopted from far and near; to ensure the uniformity of current distribution on any surface; in order to ensure the uniformity of the coating in the hole and the consistency of the coating thickness, in addition to stirring, filtering and other technological measures, pulsed current should also be used; Regularly monitor the current changes during the electroplating process to ensure the reliability and stability of the current value; check whether the copper plating thickness of the hole meets the technical requirements.

The process of thick copper circuit board. In the process of thickening copper plating, the process parameters must be constantly monitored, which often leads to unnecessary losses due to subjective and objective reasons. To make thicker copper plating, you must do the following: increase a certain value according to the area value calculated by the computer and the empirical constant accumulated in the actual production; according to the calculated current value, in order to ensure the coating of the hole For completeness, it is necessary to add a certain value on the basis of the original current value, that is, the pulse current, and then return to the original value in a short time; when the circuit board is electroplated for 5 minutes, take out whether the copper layer on the observation surface of the substrate and the inner wall of the hole is intact, It is best that all the holes are metal; a certain distance between the substrates must be maintained; when the thick copper plating reaches the required plating time, a certain current should be maintained during the removal of the substrate to ensure the subsequent substrate The surface and holes will not turn black or darken.

The circuit board factory, the multilayer circuit board factory, and the Shenzhen circuit board factory tell you the precautions for thick copper circuit boards: check the process documents, read the process requirements, and be familiar with the substrate processing blueprint; check the surface of the substrate for scratches, indentations, Exposed copper parts and other phenomena; trial processing according to the processed floppy disk, pre-inspection of the first part, and then processing all workpieces in accordance with the process requirements; preparation of measuring tools and other tools for monitoring the geometric dimensions of the substrate; selection according to the nature of the raw material for processing the substrate Suitable milling tool (milling cutter).