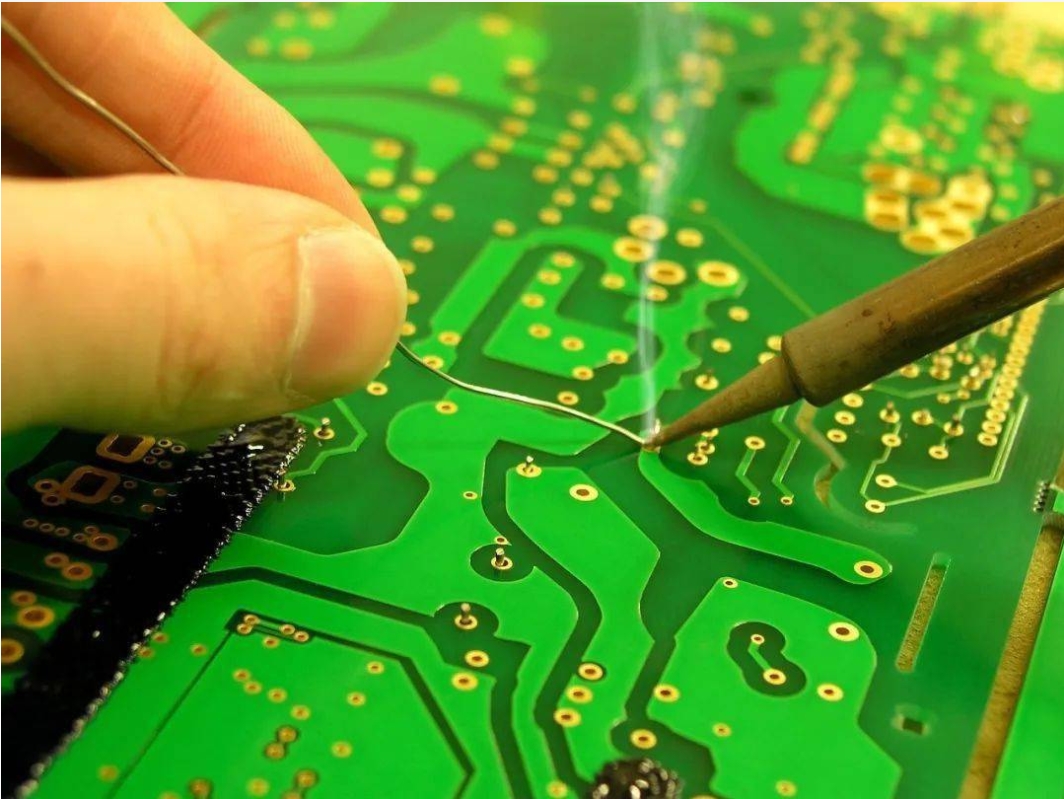

Solder and flux are indispensable materials in welding, reasonable selection of solder and flux, is to ensure the quality of welding is an important link.

Selection of solder

The role of the solder is to be welded wire or other metal parts firmly connected together.

Solder is a good conductivity of low melting point alloy, heated by the soldering iron is easy to become liquid, attached to the metal object being welded and fill the gaps around it, that is restored to the solid state after cooling, to ensure that the joints of the long-term firm and conductive good.

Solder has tin-lead solder, silver solder, copper solder and other types of solder, tin-lead solder in the general electrician work in the application of more.

Solder can be processed into strips, blocks or wires and so on. Solder wire, especially the inner filling with rosin powder (flux) rosin heart solder wire, due to the low melting point, easy to use, is the first choice of solder in welding.

Choosing the right solder is critical to the success of PCB soldering. Considering factors such as the solder's material composition, melting point, and application requirements can help improve solder quality and the reliability of electronic products.

1.Material Composition

Solder typically contains tin,lead and other metal components. Traditional lead alloy solders are composed of 60% tin and 40% lead and are suitable for most electronic components. Lead-free solder in the increasingly stringent environmental standards for electronic products is becoming popular, the main component is usually tin-copper alloy, with a high melting point. In the need to withstand high temperature occasions, you can choose silver alloy solder, these solders usually contain 3% to 5% silver.

2.Melting point

The melting point of the solder will affect the temperature control of the soldering process.Generally speaking,the melting point of brazing is lower than the melting point of the components and the PCB itself,in order to avoid thermal damage to the circuit board. For example, the melting point of leaded solder is around 183°C, while lead-free solder can have a melting point as high as 217°C,which requires special attention to choosing the right tools and equipment when soldering.

3.Application requirements

The choice of solder should also be adjusted to the specific application requirements.For example, for high temperature and high thermal load applications, it is recommended to use lead-free solder or silver alloy solder to ensure the durability and stability of the solder joint. For DIY and beginner projects, leaded solder is still a popular choice due to its ease of operation and lower melting temperature.

4.Soldering Technique Considerations

Different soldering techniques will also affect the choice of solder. For example, during selective soldering, the quality and type of flux will also affect the fluidity of the solder and its bonding with the board. Therefore, choosing the right flux and ensuring that it matches the solder is another key factor in successful soldering.

5.Solder Diameter

The diameter of the solder will affect the accuracy and efficiency of the soldering operation. Generally recommended for PCB soldering in the diameter of 0.4mm to 1.0mm range of solder wire, which is the most effective choice for most electronic projects. Selecting the proper size solder ensures the reliability and structural integrity of the solder joint.

How the solder removal from a circuit board

Removal with a solder sucker

A solder sucker is a tool designed for soldering repairs that can easily suck out solder.Aim the nozzle of the solder sucker at the solder, gently press the handle, and the solder will be sucked out.However,this method is only suitable when there is relatively little solder and requires manual operation,which is slow.

Remove with Solder Pump

Solder pump is another common tool for removing solder,which can also be used to remove the solder in the circuit board hole.To use it, the solder pump is hot-melted and aimed at the solder,and the spring is pressed to suck out the solder.Solder pumps are more efficient than solder suckers,but you need to be careful about the temperature at which they are operated.

Removal with a heater

If there is a lot of solder in the hole,you can use a heater to remove the solder after it is thermally fused.Place the board in a heater.When the heater heats up,the solder will soften and can be removed with a solder sucker or copper wire.

Removal with Copper Absorbent Wire

Copper suction wire,also known as solder silver,is a metal wire that sucks out metal materials from soldered surfaces.Insert the copper suction wire directly into the solder hole and rotate it slightly.After the solder in the copper suction wire sticks to the copper suction wire, gently flick out the copper suction wire and the handle.

Correct selection of solder and flux and mastering effective solder removal methods is the key to improving the quality and efficiency of soldering.In the solder removal from a circuit board, whether it is the use of professional solder sucker,solder pump,or through the heating and suction of copper wire and other techniques, all need to be based on the amount of solder,the location of the soldering and ease of operation and other factors to be considered in a comprehensive manner.