Equipment introduction

PCB online laser marking machine

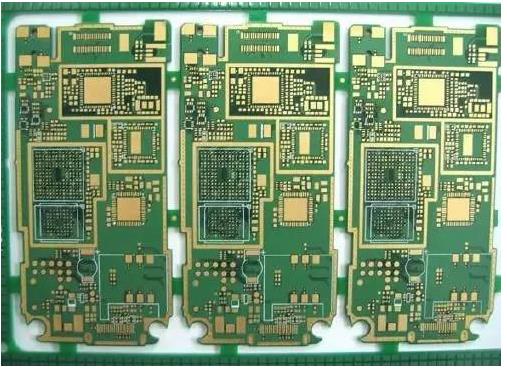

PCB marking samples

Equipment advantages:

1. According to the customer's PCB marking requirements and specific needs, three optical paths of UV laser, fiber laser, and CO2 laser can be provided;

2. Imported digital galvanometer, high processing precision, fast marking speed and stable performance;

3. It has the functions of CCD to read two-dimensional codes and bar codes synchronously, and save the data, and automatically record and alarm when it cannot be read;

4. With Badmark recognition function, it can automatically identify and hit the "X" board without engraving;

5. The built-in flap mechanism can be customized to realize double-sided engraving and double-sided code reading

6. The operation interface is humanized, easy to learn, and powerful editing functions;

7. Can be customized suction and conveying integrated board loading machine, automatic copying machine, automatic unloading machine, automatic corner machine, etc.;

8. Compared with ordinary printing methods, it has no consumables, environmental protection, pollution-free, and maintenance-free.

Precision laser cutting machine

FPC precision cutting samples

Equipment advantages

1. It adopts a marble base platform and an integrated closed structure with safe and reliable performance;

2. It adopts imported linear motor control system and imported precision scanning galvanometer, with high cutting precision and good stability;

3. Imported ultraviolet laser is used, with good spot quality, stable pulse energy and long life;

4. Using cold processing technology, the cutting edge is smooth and free of burrs;

5. It has a one-time multi-plate array cutting function to improve production efficiency;

6. Independently researched and developed software to realize intelligent design such as automatic focusing, automatic correction, automatic positioning and unique preview before cutting.