An internal PCB antenna,also known as a printed circuit board antenna, is a form of antenna in which the antenna is printed directly onto a PCB (printed circuit board). This type of antenna plays an increasingly important role in modern wireless communication devices, especially in mobile devices, IoT devices, and wireless sensor networks, where it is widely used due to its compactness, lightweight, and low cost.

Internal pcb design principles

The design principles of printed circuit board as antenna mainly include the following points:

1. choose the right board: printed wiring board commonly used boards are mainly FR-4, PTFE, etc. Different boards have different dielectric properties, you need to choose the right board according to the frequency band.

2. Smaller board thickness: When the printed wiring board is used as an antenna, the board thickness should be reduced as much as possible to make the antenna impedance match better.

3. Reasonable antenna layout: the layout of PCB antenna needs to be optimized according to the antenna type and frequency band and other factors, through electromagnetic simulation and other tools for design and optimization.

Scope of application

Printed wiring board as antenna has been widely used in wireless communication, smart home, car networking and other fields. For example, in smart watches, printed wiring boards can be used as Wi-Fi and Bluetooth antennas to realize high-speed wireless networks and device interconnection. In the automotive field, printed circuit board antenna can be embedded in the car body to realize positioning, navigation and other functions.

Circuit board antenna soldering note: how to properly solder the circuit board antenna

Soldering tool preparation

Before the circuit board antenna welding, you need to prepare the following tools:

1.Solder wire: use solder wire with a diameter of 0.6mm.

2.Solder paste: use lead-free solder paste to ensure the quality of welding.

3.Solder paste scraper: used to scrape the appropriate amount of lead-free solder paste.

4.Spot Soldering Pen: Used for soldering small parts.

Soldering point position

In the antenna welding process, the position of the soldering point is very important, different soldering point position will affect the antenna's working effect. Generally, the solder joint should be fixed on the board where the antenna is located, the position should be precise, suitable and should not move.

Soldering Methods

There are two types of soldering methods for circuit board antennas, manual soldering and heated table soldering,the following is a detailed description of the two types of soldering:

1.Manual welding

The process of manual soldering is relatively simple and does not require many tools. Before hand soldering, you need to set the position of the solder joints in order to fix the antenna to the board and reduce the movement. The diameter of the solder wire should be selected 0.6mm and the solder paste should be lead-free to ensure the quality of soldering. Preheat the solder wire on the solder joint, then use a solder paste scraper to scrape the appropriate amount of solder paste and distribute it evenly on the solder joint. While spreading the solder wire on the solder joints, use the spot welding pen to heat the solder joints, wait until the solder wire melts, the heat is transferred to the solder joints through the solder wire to complete the connection of the antenna solder joints.

2.Heating station welding

The process of heating pad welding requires the use of tools such as heating pad, compared with manual welding, heating pad welding is more suitable for welding complex circuit boards. Before the heating table welding, you need to place the antenna on the heating table, set the position of the solder joints. The temperature of the heating table should be controlled at about 200 degrees, using a lead-free solder paste scraper to distribute the appropriate amount of solder paste on the solder joints. Preheat the solder wire on the solder joint, and then heat the solder joint by the temperature of the heating table, wait until the solder wire melts and the heat is transferred to the solder joint to complete the welding of the antenna.

Circuit board antenna connection

Microcontroller antenna connection

Microcontroller antenna connection method has two main types: direct welding and connecting RF switch chip. Direct welding can simplify the line and reduce the difficulty of subsequent debugging of components, but the antenna requirements are higher; connecting the RF switch chip requires more components, but can better match the antenna and improve the performance of the antenna.

Precautions:

1.The antenna must meet the operating frequency, and impedance matching is good.

2.When welding directly, the antenna length must be measured accurately without any error.

3.When connecting the RF switch chip, the switch chip should be selected to ensure that it matches the frequency range of the antenna and the chip.

Debugging method:

1.When welding directly, you can observe the signal peak and frequency through the oscilloscope to see if they meet the requirements.

2.When connecting the RF switch chip, debug the matching network to ensure that the antenna and chip are well matched.

LoRa antenna connection

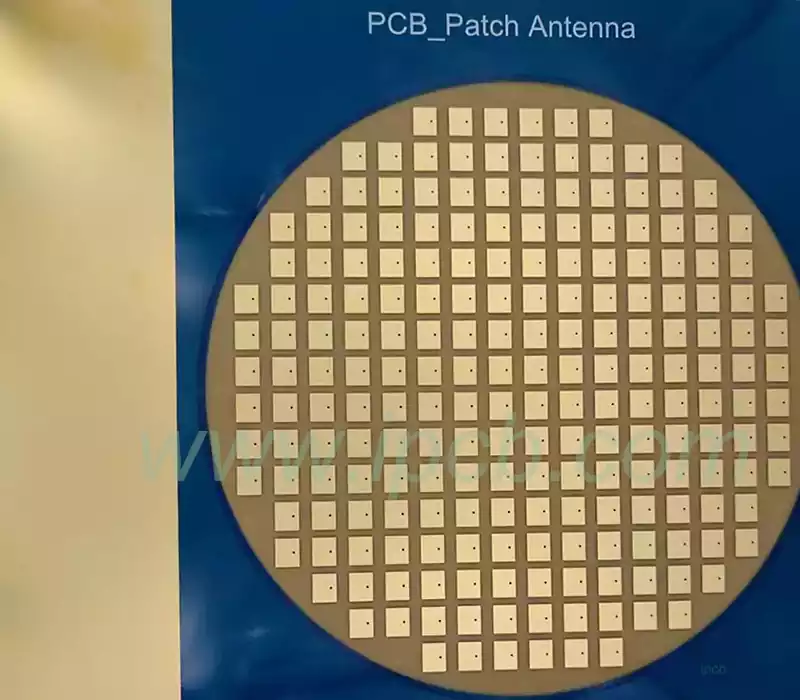

There are three kinds of LoRa antenna connection methods: PCB embedded antenna, adapter antenna and external patch antenna. PCB embedded antenna takes up little space and is suitable for occasions with limited space; adapter antenna can improve the antenna efficiency; external patch antenna is convenient to replace, but needs to take up extra space.

Precautions:

1.The antenna must conform to the operating frequency and have good impedance matching.

2.The length of the antenna must be measured accurately without any error.

3.The external patch antenna should be allowed to leave the interference source.

Debugging method:

1.PCB embedded antenna, you can through the oscilloscope to observe the signal peak and frequency to meet the requirements.

2.When adapter antenna, you can adjust the adapter parameters so as to improve the antenna efficiency.

3.When external patch antenna, you can try to adjust the antenna position and distance from the interference source to observe whether the signal quality changes.

As a key pcb component of modern wireless communication technology, internal PCB antenna is gradually becoming the mainstream choice in the industry with its excellent performance and wide application prospect. With the continuous progress and innovation of technology, we have reason to believe that it will show even more outstanding performance in the future wireless communication field.