Causes and Improvement of No Copper Defects in PCB Deep Hole Plating Holes

Causes and Improvements of No Copper Defects in Proton Plating Holes

Preface

With the continuous development and innovation of electronic products and technologies, the concept of electronic products has gradually become light and compact, and the design of printed circuit boards has also developed on the basis of small, high-density, multi-layer and end-user lines.

As the thickness of the PCB layer increases and the opening decreases, the relationship between the thickness of the hole and the diameter of the product increases significantly, and the difficulty of PTH processing is gradually increasing, which easily leads to frequent non-metallic phenomena. Appear.

Material. In consideration of these issues, this article provides specific reasons for non-metallic phenomena formed by non-metals in the PTH process through abnormal water, special design and production operations, and defines different prevention and improvement measures.

Guaranteed adrenal plasticizing performance and monitoring function are guaranteed.

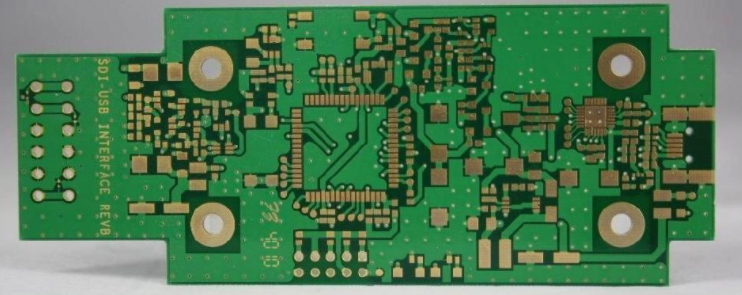

2 Principles of PCB PTH The PTH is also called "through-hole plating", which is mainly used to deposit a copper film on the substrate of a chemically insulated hole to provide a conductive layer for subsequent plating, thereby guiding the inside and outside The function of the layer.

The main process of PTH is shown below.

The chemical reactions involved are as follows: Activation: Pd2++2Sn2+-[PdSn]2+--reaction in solution to form unstable complexes [PdSn]2+-Pd+Sn4++Sn2+--most of the complexes It is reduced to metal palladium SnCl2+H2-Sn(OH)Cl+HCl--SnCl2 is hydrolyzed to form basic stannate precipitate when washed with water after activation

As SnCl precipitates, Pd cores are also deposited on the surface of the activated substrate

Copper deposition: HCHO+OH--H2+HCHOO---when Pd is used as a catalyst

This step of the reaction can proceed Cu+H2+OH--Cu+2H2O-copper ions are reduced to metallic copper under alkaline conditions

When the SNCL precipitates, the PD core is also deposited on the surface of the activated substrate.

Copper precipitation: HCHO + OH-H2-HC + PD is used as a catalyst to achieve this reaction step.

Copper (CU + H2-CU-Cu+ + 2H-Cu+2H -copper) is reduced to copper under alkaline conditions

3. Analyze the reasons and measures of free copper in the third hole. Because of the vertical and high-level high-hole electroplating products, it is difficult to exchange drugs and water in the hole during the PTH process, and it is easy for the metal in the hole to not exist. produced.

The shape of the non-metal part in the PTH processing hole in the printed circuit is obvious, and the non-metal phenomenon in the hole is similar due to various reasons. Thorough analysis and discrimination must be carried out to determine the true cause of the defect.

3.1.1 Reasons During the activation process, the content of palladium ions in the activator is not appropriate, so that the colloidal palladium is not adequately deposited on the surface of the substrate.

a. In the subsequent copper deposition process, the result of the lack of palladium ion catalyst is that there is a mediocre copper deposition on the pig wall, thereby avoiding metal defects in the pig.

b. Small bubbles infiltrate into the activation roller, causing the colloidal palladium in the cylinder to hydrolyze, so that the activation roller loses its activation function, and the copper layer cannot be deposited in the hole.

c. The pH of the solution is too low. Since the chemical precipitation of copper must be carried out under low and low conditions, when the pH value is too low, the reducing ability of formaldehyde is reduced, which affects the reaction rate of copper precipitation and leads to mediocre precipitation of copper.

d. A complex agent that forms a copper cylinder in a part of copper, forms copper hydroxide in a part of copper ions, and there is not enough copper in the copper ions to prevent precipitation reactions in the walls of the holes.

3.1.2 Improvement measures In the PTH production process, in the activation roller and the hollow copper cylinder, each cylinder component should be maintained within the range of the normal method concentration to ensure orderly chemical reactions.

In addition, the pH and temperature in the cylinder will also affect its effect. The copper is buried on the wall of the cave, which should be constantly monitored.

Due to the influence of small bubbles, the activation of colloidal palladium in the cylinder is easily hydrolyzed.

Therefore, it must be ensured that there is no leakage in the tube of the cylinder to ensure the normal reaction of the colloidal palladium.

3.2 Special design grade The shape of the non-metal wafer in the hole caused by this kind of reason is mainly the obvious defect of copper and electroplated copper plate. At the same time, there is a phenomenon that in the default range, the inner copper is smooth and thick.

3.2.1 Reasons For electroplated products with protons, the format report is usually very high. In this case, the drug-water exchange rate in the hole is greatly reduced, so that the copper deposit becomes the center of the hole that is often unbalanced during the PTH process.

Due to potential reasons, the absorption capacity of copper ions is reduced again, which directly leads to insufficient thickness of the copper coating. In the next process (external processing of patterns and pattern plating), the hole opens due to the loss of copper, so there is no metal defect in the hole.

3.2.2 Preventive measures Considering such design issues, as long as the design manuscript remains unchanged, the copper and sheet electrical parameters can be adjusted appropriately to ensure that the copper thickness is sufficient to prevent copper loss in the filter.

Subsequent process.

The main method can extend the copper impregnation time, or absorb the pre-dipped copper plated copper after the copper impregnation process is completed to ensure the thickness of the copper absorption layer, and it can also be used in a short time (8asf * 30Min).

After the copper casting process, the copper is immersed on the plate after the plate is electroplated, and the copper holes are thickened enough after the electroplating of the plate.

In addition, the copper immersion conditions remain unchanged, which appropriately reduces the current density of the plate, prolongs the plating time, and ensures that the copper ions are sufficient in the cavity and the coating is uniform.

3.3 Production business The main reason for the main non-metal in the PTH hole is abnormal equipment and abnormal operation. The characteristics of the wafer include remaining foreign bodies in holes, plating, and plating.

3.3.1 The main abnormality of the reason is: abnormal high-pressure water washing occurs before the short-chain chlorinated lime and during the PTTS process, resulting in short-term non-discharge, such as drilling and copper powder, resulting in abnormal medical treatment in the pores. comminicate.

PTH leads to low copper deposition in the hole; in addition, after PTH, abnormal copper deposition behind the hole due to abnormal activation and abnormal shipwreck equipment of the copper bottle.

During this process, abnormal vibration and abnormal vibration, or the amplitude and frequency of unqualified vibration in the activation cylinder and immersion copper cylinder, will also cause the nozzle to unload in the hole, which will affect the medicine and Exchange of water.

ipcb is a high-precision, high-quality PCB manufacturer, such as: isola 370hr PCB, high-frequency PCB, high-speed PCB, ic substrate, ic test board, impedance PCB, HDI PCB, Rigid-Flex PCB, buried blind PCB,advanced PCB,microwave PCB, telfon PCB and other ipcb are good at PCB manufacturing.