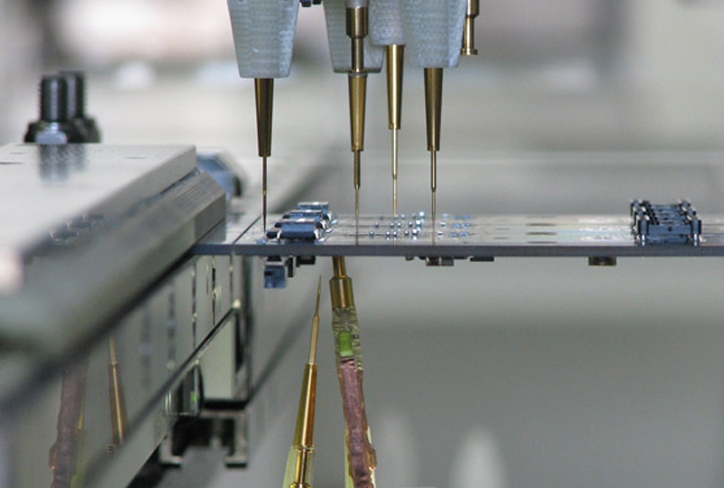

Flying probe testing is the latest solution to some of the main issues in electrical testing. It replaces needle beds with probes and uses multiple motor-driven,

fast moving electrical probes to make contact with the pins of the device and perform electrical measurements.

PCB flying probe test

Advantages of PCB flying probe testing:

Flying probe testing is a non-contact PCB inspection method that uses a movable independent probe to accurately locate the test point for electrical

performance testing according to a pre-set testing program. The advantages of this testing method include:

1. High testing accuracy: Flying probe testing can accurately locate any testing point and has good detection ability for high-density and fine pitch circuit boards,

ensuring the accuracy of testing.

2. Low cost: No need to make expensive specialized testing racks, especially suitable for new product development, sample validation,

or small batch production stages, which can effectively save costs.

3. High flexibility: No need to customize a dedicated testing rack, able to quickly adapt to PCB boards of various sizes, shapes, and complexities,

especially suitable for small batches, multiple varieties, and rapidly iterating products.

4. The flying probe test is also applicable to the testing of ceramic PCB circuit boards, which ensures the elimination of differences in the production process

by inspecting the completed PCB circuits.

Flying probe testing is an essential process in PCB testing, which is a non-contact testing technique that uses a precision robotic arm to carry probes and

detect circuit connectivity by approaching the testing point without touching the PCB.

Test bench testing is a specialized testing fixture designed for specific PCB boards. By contacting the probes on the test bench with the

testing points on the PCB board, comprehensive testing of the PCB board is achieved. This testing method has the advantages of high precision and high stability,

and is suitable for testing large quantities and fixed varieties of PCB boards. But the production cost of the test stand is high, and once there is a change

in the PCB board design, the test stand needs to be remade.

The role of PCB flying probe testing

The role of flying probe testing in PCB is mainly to analyze the soldering quality of the circuit board and the failure of electronic components,

in order to ensure the performance and reliability of the circuit board.

1) Flying probe testing is a high-precision testing method that can quickly detect the solder joints of circuit boards, including identifying and locating abnormal situations

such as continuity, short circuit, and solder joints. This testing method is more efficient and accurate than traditional manual testing, and can greatly improve production efficiency and product quality. It can also provide important guarantees for the performance and reliability of the circuit board, ensuring that the product can operate stably in complex applications and harsh environments

2) The flying probe testing machine can check for short circuits, open circuits, and component values, using a camera to help locate lost components

and check for directional component shapes, such as polarized capacitors. With the probe positioning accuracy and repeatability reaching the range of 5-15 microns,

the flying probe testing machine can accurately detect the tested unit.

Flying probe testing is a non-contact PCB inspection method that uses a movable independent probe to accurately locate the test point for

electrical performance testing according to a pre-set testing program.