The specification of the distance from the silk to solder mask clearance is governed by the international standard IPC-7351, which details the minimum distance that should be maintained between different types of silkscreens and soldermasks.Commonly, the distance between the silkscreen and the soldermask must be more than 0.1mm, which is designed to prevent the silkscreen from overlapping or clashing with the soldermask during the manufacturing process, thus maintaining the accuracy and reliability of electronic assemblies.

For special silkscreens that contain design guidelines or functional descriptions, such as pin markings, the distance from the silk to solder mask clearance is even more stringent, and must be greater than 0.25 mm. These silkscreens occupy an even more critical position in electronic products, and their accuracy and clarity are decisive for the correct assembly and use of the product.

The importance of the spacing between the silk to solder mask clearance.

The spacing between the silk to solder mask clearance not only affects the appearance of electronic products, but also has a critical impact on their electrical performance and reliability. If the spacing between the silkscreen and the soldermask is too small, it may cause the silkscreen to be covered or partially covered by the soldermask during the manufacturing process, thus reducing the clarity and readability of the silkscreen. This not only makes the assembly of electronic products more difficult, but also raises the risk of mishandling or malfunctioning in subsequent use.

The Spacing Problem in PCB Design

1.Spacing between wires

It is recommended that the distance between the wiring and the wiring should not be less than 4 mils.The minimum line spacing is also the distance between lines and pads.The conventional 10mil is more common.

2.Pad aperture and pad width

If the aperture of the solder mask is mechanically drilled,the minimum should not be less than 0.2mm.If laser drilling is used,it is recommended that the minimum should not be less than 4mil. The aperture tolerance varies slightly depending on the plate,and can generally be controlled within 0.05mm.The minimum width of the welding pad should not be less than 0.2mm.

3.Spacing between pads

It is recommended that the spacing between pads should not be less than 0.2mm.

4.Distance between the copper sheet and plate edge

The distance between the charged copper sheet and the edge of the PCB board should preferably not be less than 0.3mm.If copper is laid on a large area,it is usually necessary to have an inward shrink distance from the board edge,usually set at 20mil.

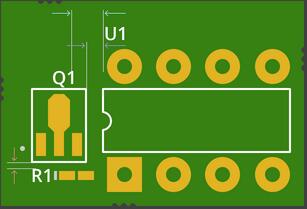

5. Distance from silkscreen to solder mask

Screen printing is not allowed to cover the solder pad,as if the screen is covered with the solder mask,the screen area will not be able to be tinned during soldering,which will affect the installation of components.

It is generally required to reserve a spacing of 8mil.If it is because the area of some PCB boards is tight,it is barely acceptable for us to achieve a spacing of 4mil.If the silkscreen accidentally covers the solder pad during design,the silkscreen part left on the solder pad will be automatically eliminated during manufacturing to ensure tin on the solder pad.

When we draw a silkscreenframe,we will make it slightly larger than the solder pad.Generally,the distance between the silkscreen frame and the edge of the solder pad is kept at about 6mil to ensure production and installation needs.If the drawing is too close,it will cause the silkscreen frame to be drawn on the solder mask.Generally,before production,CAM will remove the silk screen drawn on the solder mask to ensure the normal production of PCB boards and SMT chips in the later stage.