1. Turn on the SMT placement machine

1. Turn on the handle type main power supply on the upper left side of the machine

2. Press the green button "POWER ON",

3. Turn on the red emergency stop switch EMERGENCY STOP, the RESET red button flashes, just press it.

4. The green light key START flashes, and then press it to return to zero.

2. Confirm the content of the SMT patch program

1. Confirm whether the D-axis material station is correct.

2. Confirm the program name.

3. Test the center point and brightness of the nozzle.

4. Set the production schedule number.

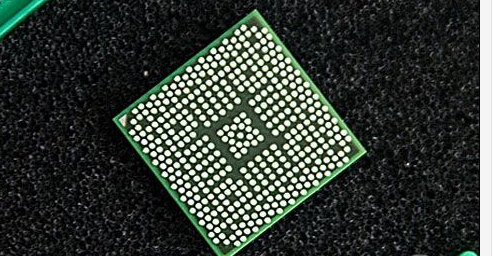

3. CP6 high-speed SMT placement operation content

1. Place the chip resistors, capacitors, inductors, crystals, and IC special-shaped objects in the correct position of the copper foil.

2. The displacement of chip resistors, capacitors, inductors, crystals and IC special-shaped objects shall not exceed 1/4 of the position of the copper foil.

3. The inclination angle of all SMD components is within 30 degrees.

4. It is not allowed to have parts sticking backwards.

Four, SMT patch processing matters needing attention

1. After the installation is completed, there should be no missing parts, wrong parts, reverse, misalignment, floating height and other undesirable phenomena. Once found, promptly notify

Relevant technical personnel make adjustments

2. Feeding should be timely, accurate and recorded. Resistance and capacitance should be tested correctly and then record the "feeding/refueling/refilling record sheet" before starting up.

3. The flight attendants clean up the material discharge on time every two hours and make effective countermeasures, which shall be recorded in the "Discharge Daily Report".

4. The production quantity per hour must be checked and filled in the "Production Times".

5. When handing over the shift, carefully check whether there are patch parts in the distribution box that are sucked into it, and then discard it after confirming that it is clean.

Five, SMT handover

※The transferor and transferee should hand over all the work items face to face and sign them before leaving. The handover items are as follows:

1. The parts handover clearly explain the parts placement and use precautions of the well-produced species.

2. Machine warranty: including machine internal maintenance and appearance wiping.

3. Environmental sanitation: clean up, clean and maintain machines, floors, and desktops.

Six, SMT equipment maintenance precautions

※Daily maintenance

1. Check and drop materials in the waste box: one hour before the shift, pour the waste in the machine into the designated box to clean up whether there are any patch parts, and then discard it after confirming that it is correct.

2, NOZZLE center point and brightness test, this action should be carried out before production, if the head shows X, it should be dealt with by a technician in time

3. Maintenance of the inside and outside of the machine: Do not leave any idle debris or parts inside the machine, keep it clean, and often wipe the appearance with sprinkles.

4. Except for the parts in the waste box, other parts that are dropped from the machine and the ground cannot be reused.

※Weekly maintenance

1. Knife inspection and light source cleaning: It is found that there are parts with continuous cutting, and the knives should be replaced in time. The CCD lens should be wiped with alcohol frequently and kept clean.

※Monthly maintenance

1. Lubricate the X, Y, D axis and all the bearings and movable joints: wipe the original oil with a cloth, and refill with new oil (X, Y, DLM H IMG, AFC oil on the F, Q axis, and the TABLE up and down LRL3 oil)

2. Remove all heat dissipation devices of the SMT machine for cleaning.

3. The maintenance actions must be recorded in the "Machine Maintenance Table"

Seven, SMT placement machine

1. Press the red emergency stop switch EMERGENCY STOP

2. Press the green button POWER OFF again,

3. Turn off the main power supply with the handle on the upper left side of the machine.