Talk about the specific steps of PCB board copy

1. Get a piece of PCB, first record the model, parameters, and position of all vital parts on the paper, especially the direction of the diode, the tertiary tube, and the direction of the IC gap. Use a digital camera to take two photos of the location of vital parts. Nowadays, the PCB circuit board is getting more and more. The diode transistor on the top is not noticed at all.

2. Remove all the multi-layer boards and copy the boards, and remove the tin in the PAD hole. Clean the PCB with alcohol and put it in the scanner. When the scanner scans, you need to raise the scanned pixels slightly to get a clearer image.

Then lightly polish the top and bottom layers with water gauze until the copper film is shiny, put them in the scanner, start PHOTOSHOP, and scan the two layers in separately in color. Note that the PCB must be placed horizontally and vertically in the scanner, otherwise the scanned image cannot be used.

3. Adjust the contrast and brightness of the canvas to make the part with copper film and the part without copper film have a strong contrast, then turn the second image into black and white, and check whether the lines are clear. If not, repeat this step. If it is clear, save the picture as black and white BMP format files TOP.BMP and BOT.BMP. If you find any problems with the picture, you can use PHOTOSHOP to repair and correct it.

4. Convert the two BMP format files to PROTEL format files, and transfer to two layers in PROTEL. For example, the positions of PAD and VIA after two layers basically coincide, indicating that the previous steps have been done well, if there is a deviation, Then repeat the third step. Therefore, PCB copying is a job that requires patience, because a small problem will affect the quality and the degree of matching after copying.

5. Convert the BMP of the TOP layer to TOP.PCB, pay attention to the conversion to the SILK layer, which is the layer, and then you can trace the line on the TOP layer, and place the device according to the drawing in the second step. Delete the SILK layer after drawing. Keep repeating until all the layers are drawn.

6. Import TOP.PCB and BOT.PCB in PROTEL and combine them into one picture and it will be OK.

7. Use a laser printer to print TOP LAYER and BOTTOM LAYER on transparent film (1:1 ratio), put the film on the PCB, and compare whether there is any error. If it is correct, you are done.

Talk about how to distinguish the number of layers of the PCB board

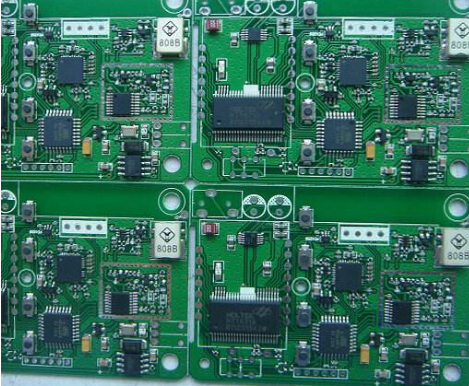

The substrate of the PCB board itself is made of insulating and heat-insulating materials that are not easy to bend. The small circuit material that can be seen on the surface is copper foil. The copper foil was originally covered on the entire PCB board, but part of it was etched away during the manufacturing process, and the remaining part became a network of small circuits NS. These lines are called wires or wiring, and are used to provide circuit connections for parts on the PCB.

Usually the color of PCB board is green or brown, which is the color of solder mask. It is an insulating protective layer that can protect the copper wire and prevent parts from being welded to the wrong place. Multilayer boards are now used on motherboards and graphics cards, greatly increasing the area that can be wired.

Steps/Methods

1. Multilayer boards use more single or double-sided wiring boards, and put a layer of insulating layer between each layer of boards and press them together.

2. The number of layers of the PCB board means that there are several independent wiring layers. Usually the number of layers is an even number and includes the outer two layers. The common PCB board generally has a structure of 4 to 8 layers. The number of layers of many PCB boards can be seen by looking at the cut surface of the PCB board. But in fact, no one can have such good eyesight.

3. The circuit connection of the multi-layer board is through buried via and blind via technology. Most motherboards and display cards use 4-layer PCB boards, and some use 6, 8-layer, or even 10-layer PCB boards.

4. If you want to see how many layers the PCB has, you can identify it by observing the via holes, because the 4-layer board used on the motherboard and the display card is the first and fourth layers of wiring, and the other layers have other uses ( Ground wire and power supply). Therefore, like the double-layer board, the via hole will penetrate the PCB board.

5. If some vias appear on the front of the PCB but cannot be found on the reverse, then it must be a 6/8-layer board. If the same via holes can be found on both sides of the PCB, it will naturally be a 4-layer board.