Red glue is a polyolefin compound, belongs to the SMT material, and the difference with the solder paste is that it is cured when it is heated, when the temperature reaches 150 ℃, the red glue begins to turn from a paste into a solid.

What is red glue on pcb?

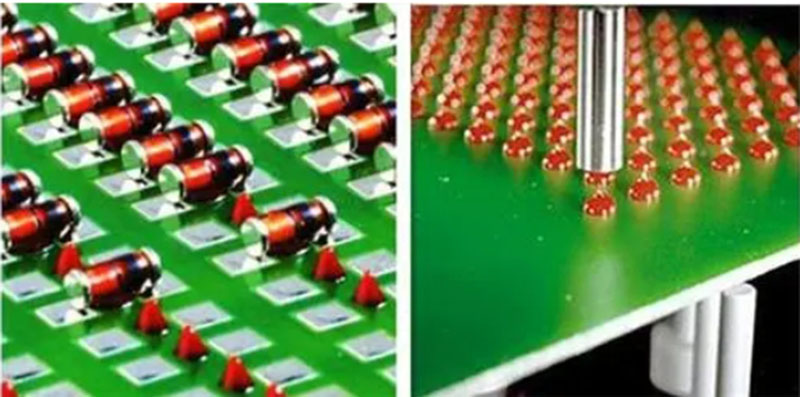

In the SMT (surface mount technology) and DIP (dual in-line package) mixed process, in order to avoid the single-sided reflow and wave soldering of the two over the furnace, usually in the PCB (printed circuit board) wave soldering surface of the chip components and devices in the centre of the point coated with red glue. In this way, when passing through the wave soldering, the components can be tinned in one go, thus omitting the solder paste printing step.

The formal name for the ‘red glue’ process in SMT is the SMT ‘dispensing’ process. Because most of the glue colour is red, so people used to call it ‘red glue’, in fact, there are also yellow glue, which is usually with the circuit board surface ‘soldermask’ called ‘green paint This is similar to what we usually call ‘green paint’ on the surface of circuit boards. Resistors. Capacitors and other small components underneath, we can often see a mass of red gel, that is red glue. The red glue process was originally developed when there were still many electronic components that could not be immediately converted from DIP packages to SMD (surface mount device) packages.

When a circuit board contains both DIP and SMD components, how can these components be arranged so that they can both be automatically soldered to the board? A common practice is to design both DIP and SMD components on the same side of the board, using solder paste printing and reflow ovens to solder the SMD components, while the DIP components can be soldered in one pass through the wave soldering process because all of the pins are exposed on the other side of the board. This usually requires two soldering processes to complete the soldering of all components.

In order to save space on the PCB layout so that more components can be placed, it is sometimes necessary to place SMT components on the Bottom side of the board as well. This is done by attaching the components to the board using red glue and then passing the board through a wave soldering oven to allow the components to be tinned and bonded to the pads on the board, while ensuring that the components don't fall into the high temperature of the wave soldering oven.

If it is desirable to reduce the process and complete the soldering in a single pass, then consider using through-hole reflow soldering. However, many DIP components cannot withstand the high temperature environment of reflow soldering, so this method is not suitable. Only some large companies producing large quantities of products may purchase DIP components that can withstand high temperatures to use through-hole reflow. And general SMD components have been designed to withstand the temperature of reflow soldering. Although the temperature of reflow soldering is higher than that of wave soldering, it is not a problem for SMD components to stay in the wave soldering oven for a short time. However, since the temperature of the tin oven must be higher than the melting point of the solder paste, SMD components printed with solder paste cannot pass through the wave soldering oven without the components falling into the oven as the paste melts. Therefore, it is necessary to use red glue to fix the SMD components.

The role of red glue on PCB mainly includes the following points:

Red glue mainly plays a fixed and auxiliary function, while the real welding work is done by solder.

In the wave soldering process, red glue is used to prevent components from falling off when the printed board passes through the solder slot, ensuring that the components can be firmly fixed on the printed board.

Red glue also plays a key role in the double-sided reflow soldering process. It ensures the quality of the soldering by preventing large devices on the side that has already been soldered from falling off due to heat melting of the solder.

In the reflow and pre-coating processes, red glue also prevents components from shifting and standing up during the placement process, ensuring that components can be accurately positioned on the printed circuit board.

In addition, red glue can be used as a marker. When the printed board and component batch change, you can use red glue to mark, in order to better management and tracking.

The standard operation process of SMT red glue is elaborated as follows:

SMT red glue process standard operating order in turn: screen printing operation → (dispensing step) → component placement → (curing process) → reflow soldering → cleaning operations → quality inspection → maintenance rework → end of the process.

1.Silk-screen link:This step is designed to solder paste (or solder paste) and red glue (that is, patch adhesive) printed accurately to the PCB (Printed Circuit Board) on the pads, laying the groundwork for the subsequent components of the soldering. The equipment needed to perform this operation is a screen printer, which is usually located at the beginning of the SMT production line.

2.Dispensing step:This step involves the precise dripping of red glue onto the PCB at a specified location, with the main purpose of fixing the electronic components firmly onto the PCB. The equipment required to perform this task is a dispenser, which may be located at the start of the SMT line or at a subsequent location on the inspection equipment.

3.Component placement:The task of this step is to precisely place the surface mount components on the PCB in the intended position. The equipment required to perform this operation is the placement machine, which is usually located in the SMT line immediately after the screen printing machine.

4.Curing:The purpose of this step is to melt the red glue (mounting adhesive) by heating it so that the surface mount components are tightly bonded to the PCB. The equipment for this operation is the curing oven, which is located after the placement machine and is also part of the SMT production line.

5.Reflow soldering:The function of this step is to melt the solder paste to ensure that the surface mount components and PCB board to form a strong solder connection. The equipment for this operation is the reflow oven, which is also located after the mounter and is an important part of the SMT production line.

6.Cleaning:This step is designed to remove harmful residues, such as flux, from the assembled PCB. The equipment for this operation is a cleaning machine, the location of which can be flexibly arranged according to the specific layout of the production line, both online and offline.

7.Quality Inspection:The purpose of this step is to comprehensively inspect the soldering quality and assembly quality of the assembled PCB board. The required testing equipment includes magnifying glass. Microscope. In-circuit tester (ICT). Flying probe tester.Automatic Optical Inspection (AOI) system, X-RAY inspection system and function tester. These testing equipment can be flexibly configured according to the testing requirements in the appropriate location on the production line.

8.Repair and rework:For quality inspection found in the faulty PCB board, this step will be necessary rework processing. The tools required include hot air guns. Soldering iron and rework workstation. These tools can be configured in any convenient location on the production line.

SMT red glue plays a vital role in electronics manufacturing, not only providing component fixing and support, but also ensuring the quality and reliability of the soldering process. As electronic product design continues to advance and become more complex, the demand for red adhesive applications will continue to grow and become an integral part of the electronics manufacturing industry.