LED for PCB applications are becoming increasingly widespread in the modern electronics manufacturing industry. As an energy-efficient, high-performance, and flexible lighting solution, LEDs have become a crucial component in many electronic devices. Integrating LEDs into PCBs not only significantly enhances product performance but also provides designers with more room for innovation. In this article, we will explore the technical aspects of LED for Printed Circuit Board, the key design and production considerations, and its future prospects.

First, LED for PCB design requires strict adherence to heat dissipation standards. LEDs are highly efficient and consume relatively low power, but they generate significant heat when illuminated for long periods. If the heat is not dissipated effectively, it can lead to decreased performance or even damage to the PCB. Therefore, in PCB design, materials with high thermal conductivity, such as metal substrates, are commonly used to optimize heat dissipation, thereby extending the lifespan of the LEDs.Another critical factor in LED for Printed Circuit Board technology is the soldering process. Since LED components need to be precisely installed on the PCB, the soldering quality directly impacts the performance and stability of the LEDs. During soldering, temperature control is crucial—excessive heat can damage the LED, while insufficient heat may result in poor soldering connections. Manufacturers often rely on automated precision soldering equipment to ensure that every LED operates perfectly under optimal conditions.

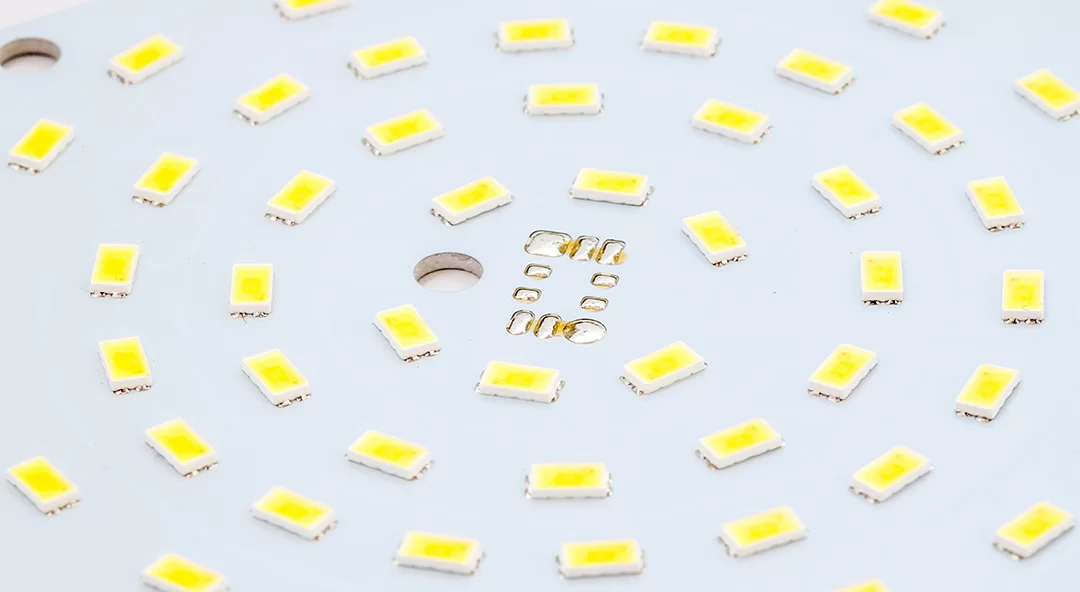

LED for PCB

Third, LED for PCB layout design is equally important. Due to the diverse application scenarios of LEDs, designers need to arrange the LEDs on the board based on specific product requirements. For example, in displays or lighting devices, the arrangement of LEDs directly affects the uniformity and quality of illumination. Therefore, during the PCB design process, professionals often use specialized design software to simulate and optimize LED placement, ensuring that each LED emits light evenly to meet user needs.In addition to heat dissipation and layout, LED for Printed Circuit Board also has special requirements for the materials used in the circuit board. Typically, LED applications use metal-core PCBs (such as aluminum-based boards) because these materials possess excellent thermal conductivity, quickly dissipating the heat generated by the LEDs. The strength of the aluminum-based board also ensures that it can support the LEDs during long-term operation without deforming or being damaged by thermal expansion.

It is worth mentioning that LED for Printed Circuit Board is widely used not only in consumer electronics but also in industries like medical, automotive, and industrial sectors. For example, automotive LED headlights and industrial LED indicators rely on high-performance PCB designs and precise LED components. In these applications, LEDs are not only required to meet high brightness and low power consumption standards but must also exhibit characteristics like vibration resistance and high-temperature tolerance, presenting greater challenges to PCB design and production.With ongoing technological advancements, the future of LED for PCB holds immense potential. As LED technology continues to mature, particularly with the development of mini-LEDs and flexible LED technology, the design and manufacturing of LED PCBs will become more versatile and efficient. This will not only enable designers to realize more creative ideas but also offer consumers more energy-efficient and high-performing products.

LED for PCB is also a key driver of sustainability in terms of environmental impact. Compared to traditional lighting, LEDs consume less energy and have a longer lifespan. This helps reduce electronic waste and lowers energy consumption, contributing positively to environmental protection. Many electronics manufacturers are now incorporating eco-friendly principles into their LED and PCB designs, developing a range of greener and more sustainable products.Finally, the advancements in LED for Printed Circuit Board technology would not be possible without progress in materials science, electronic engineering, and automation. As more advanced materials and techniques are introduced into PCB design and manufacturing, the performance of LED circuit boards will continue to improve. We can expect to see more efficient, intelligent, and multifunctional LED circuit boards in various applications in the future.

In summary, LED for PCB will play an increasingly important role in electronics manufacturing. From performance, environmental sustainability, to design flexibility, the integration of LEDs and PCBs represents a key direction for the future development of the electronics industry. Through continuous technological innovation and optimization, LED circuit boards will play an even more crucial role in the future of smart devices, industrial control systems, medical equipment, and more.