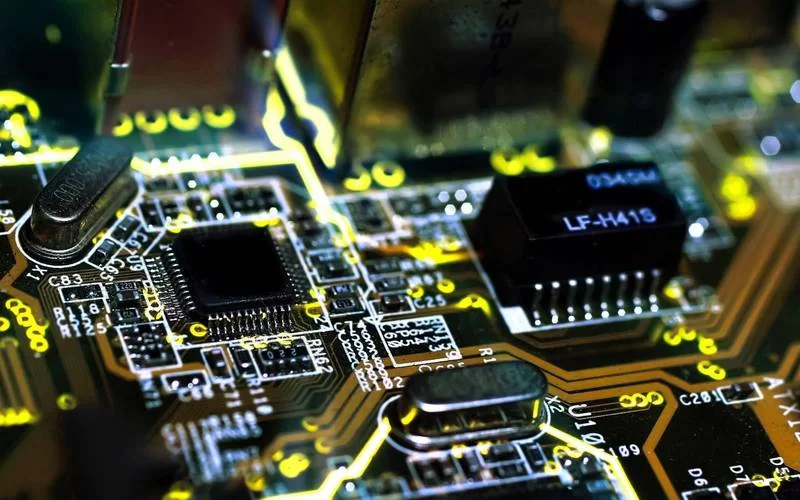

The HDD PCB board is one of the key components of a hard disk drive (HDD), determining the performance, reliability, and efficiency of data handling within the HDD. As the "nerve center" of the HDD, the PCB board controls all the functions of the hard drive and communicates with other components of the computer. Through the integrated circuits on the PCB board, the HDD is capable of performing data reading, writing, seeking, and transferring tasks. Hence, the design and manufacturing of the Hard disk circuit board are critical to the overall quality and performance of the hard drive.

The Hard Disk Drive Printed Circuit Board (HDD PCB) is one of the key components of a hard drive. It is composed of one or more layers of glass fibre laminates with many electronic components including integrated circuits, connectors, capacitors, etc. The hard disc circuit board plays an important role in connecting and controlling the various components of the hard disc.

Hard disc circuit board has the following main functions.

1.Control of hard disc read and write operations: hard disc circuit board on the controller chip (Controller Chip) is responsible for controlling the hard disc read and write operations. It receives instructions from the computer,and will be converted to the corresponding electrical signals, through the connector to the magnetic head and disc, to achieve the data reading and writing.

2.Connection of hard disc components: The hard disc circuit board has several connectors for connecting the hard disc spindle motor, magnetic head motor, magnetic head and other components, these connectors transfer signals and control between different components through wires.

3.Power Management: The Voltage and Current Management Module on the HDD circuit board is responsible for controlling the power supply and management of the HDD. It ensures the stability and adaptability of the power supply of the hard disc, and at the same time realises the power saving and automatic hibernation of the hard disc through the power management function.

HDD PCB board

HDD PCB board manufacturing processes directly impact the overall performance of the hard drive. The wiring density, number of layers, and material selection of the PCB affect the read/write speed of the hard drive.To enhance the durability of the HDD, manufacturers often adopt multilayer board designs and utilize advanced soldering techniques and automated inspection technologies to ensure every circuit connection is precise. High-quality Hard disk circuit boards not only extend the hard drive's lifespan but also improve the reliability of data transmission.Hard disk circuit board fault detection and repair are equally important. Since the PCB board controls critical functions of the hard drive, any malfunction could lead to drive failure or even data loss. Therefore, hard drive manufacturers often implement multiple testing mechanisms during production, such as Automated Optical Inspection (AOI) and functional testing, to ensure the quality of each PCB board. Furthermore, when an Hard disk circuit board fails, repairing or replacing it is one of the primary methods to recover hard drive data.

Hard disk circuit board innovations are continuously evolving alongside advancements in storage technology. As solid-state drives (SSDs) and other new storage solutions become more prevalent, HDD manufacturers are working on improving the PCB boards to compete in terms of speed, reliability, and cost-efficiency. Enhanced materials, optimized designs, and better integration with firmware allow Hard disk circuit boards to remain competitive, offering valuable storage solutions in various industries such as data centers, cloud storage, and personal computing.As the need for data storage grows exponentially in the digital age, Hard disk circuit boards must also adapt to new demands in performance, capacity, and efficiency. In data-intensive industries like finance, media, and artificial intelligence, HDDs need to handle massive amounts of data quickly and reliably. Thus, improvements in Hard disk circuit board technology are critical for supporting faster data transfer rates, enhanced durability, and better thermal management, allowing hard drives to meet the increasing needs of modern data storage solutions.

HDD PCB board have proven themselves as the foundation of high-capacity data storage devices. However, with the growing complexity of modern computing environments, these boards must support even greater precision, efficiency, and robustness. Manufacturers are now incorporating AI-based diagnostics and machine learning algorithms into PCB design to predict potential failures, optimize thermal management, and enhance performance without sacrificing quality. This trend towards smarter, more adaptive PCB boards will further drive innovation in HDD technology.Sustainability is another growing focus in the development of Hard disk circuit boards. As environmental regulations become stricter, manufacturers are shifting to more eco-friendly materials and production processes. By using less harmful chemicals and reducing waste, the industry is contributing to a greener future while continuing to deliver high-quality storage solutions. The future of Hard disk circuit boards lies not only in technological advancements but also in sustainable practices that minimize environmental impact.

The HDD PCB board is the backbone of hard drive technology, carrying the critical tasks of data transmission, control, and stability. Whether in personal computers or enterprise storage, the quality and design of the Hard disk circuit board directly affect the performance and reliability of the hard drive. As hard drive technology continues to evolve, the design and production processes of Hard disk circuit boards will also progress, providing better support for more efficient and reliable data storage solutions in the future.