PCB fabrication has a significant impact on product quality and cost. Therefore, it is important to consider whether a PCB fabricator can produce high quality PCBs from fabric at a low price.

Almost all electronic devices, from electronic watches and calculators to computers, electronic communications equipment, and military weapons systems, use printed circuit boards (PCBs) to electrically interconnect integrated circuits and other electronic components. The most fundamental success factor in the research and manufacturing of a significant number of electronic products is the product's PCB design and PCB fabrication.PCB design and PCB fabrication affect the quality and cost of the product.

IPCB is a PCB fabrication company specializing in developing and fabricating high-quality PCB. Focus on providing professional PCB fabrication services to customers. The PCB fabrication factory of iPCB covers an area of 23,000 square meters and employs 280 people, of which more than 35% are professional and technical personnel. IPCB focuses on high-frequency microwave PCB, HDI PCB, IC Substrate,rigid-flex PCB, multilayer PCB, Rogers PCB, 6 layer PCB fabrication, and 2 layer PCB fabrication. Products are widely used in Industry 4.0, Communication, Industrial Control, Digital,Power supply, Computer,Automobile, Medical, Aerospace, Instruments, Meters, Internet of Things and other fields. Customers are distributed in China and Taiwan, South Korea, Japan,the United States, Brazil, India, Russia, Southeast Asia, Europe, and other parts of the world. In terms of PCB fabrication, ipcb has continuously improved the PCB fabrication process and solved PCB technology and PCB fabrication problems. ipcb has always adhered to the purpose of fabrication high-quality PCB products. ipcb uses advanced PCB equipment and PCB production lines to become China's best PCB fabrication company.

PCB fabrication service factory

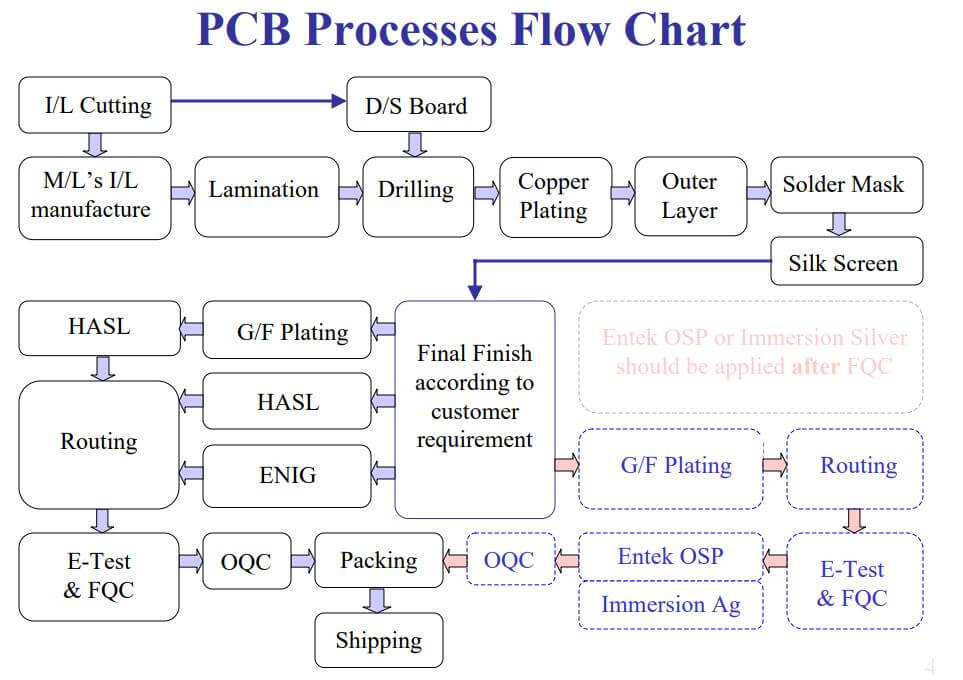

What is the PCB fabrication process?

PCB fabrication process is more complicated. It involves a wide range of functions, from simple mechanical processing to complex automated processing, common chemical reactions, photochemical, electrochemical, thermochemical, and other processes, computer-aided design CAM, and many other aspects of knowledge.Moreover, there are many process problems in the production process, and new issues will be encountered from time to time. Some of the problems disappear without finding out the cause. Because the PCB Fabrication process is a discontinuous assembly line form, any problem in any link will cause the entire line to stop Production. Or, as a consequence of a large number of scraps,if PCB is scrapped, they cannot be recycled and reused. The work pressure of process engineers is relatively high, so many engineers have left the industry and turned to PCB equipment or material vendors to do sales and technical services.

PCB substrate is made of an insulating material and is not easy to bend. Therefore, the small circuit material seen on the surface is copper foil.The copper foil is covered initially on the entire board and part of it during the PCB fabrication. After being etched away, the remaining parts become net-like small circuits.These circuits are called conductor patterns or wiring and provide circuit connections for details on the PCB.

To fix the parts on the PCB,we solder their pins directly to the wiring.On the most basic PCB (single-sided board), the pieces are concentrated on one side, and the wires are focused on the other. So It is necessary to make holes in the board so that the pins can pass through the board to the other side,so the pins of the parts are soldered on the other side. Because of this, the front and back sides of the PCB are called Component Side and Solder Side.

If some parts on the PCB need to be removed or reinstalled after the Production is completed,then the socket will be used when the part is installed.Since the socket is directly soldered on the board, the pieces can be disassembled and assembled at will.

For more details of the PCB fabrication process, please Download the PCB fabrication process PDF - ![]() PCB fabrication process pdf.

PCB fabrication process pdf.

PCB fabrication process

In the electronic product processing industry, the PCB board is one of the critical electronic components indispensables. PCB board has a variety of types, such as high-frequency PCB board, microwave heating PCB board and other types printed PCB board in the sales market has made a particular reputation. PCB Fabrication companies have a unique manufacturing process for each kind of sample. But generally speaking, the following three factors must be considered in PCB board production and processing.

1.The selection of PCB board

The PCB board can be divided into organic chemical and inorganic materials. Each raw material has its unique advantages. Therefore, the type of PCB board needs to consider the following factors clearly: the performance of dielectric gas, the type of copper foil, the thickness of base groove, Production and processing characteristics, and so on. Among them, The surface thickness of the copper foil is the primary condition to endanger the features of PCB. Generally speaking, the thinner the thickness is, the more convenient the etching process is, and the higher the precision level of the drawing is.

2.The setting of the PCB fabrication process

The natural environment of the PCB Fabrication workshop is a very critical side. Also, working temperature and air relative humidity control is a significant factor. If the working temperature transition is too apparent, it may cause the plate on the rotary hole to rupture. On the other hand, if air relative humidity is too large, the characteristic that nuclear power generation has terrible harm to the plank with a solid ability to absorb water behaves in the performance plane of dielectric gas. Therefore, it is necessary to maintain appropriate natural environment standards during PCB Fabrication.

3.The selection of PCB fabrication process

PCB Fabrication is very vulnerable to the damage of various elements. The production and processing processes, such as the number of layers, caving processing technology, and surface coating solution, may cause damage to the finished product quality of PCB. Therefore, in the natural environment of this production process, PCB Fabrication is carried out by integrating the characteristics of manufacturing machinery and equipment. Considering that, flexible adjustment can be carried out according to different PCB board types and production and processing requirements.

In general, PCB Fabrication must consider the selection of the plate, the production process setting, and the selection of the production process. In addition, the solution of PCB board construction materials and the way of opening materials are a level that must be carefully selected, which is closely related to the glossiness of the finished products of the printed board of power circuit packaging.

What are the common mistakes in PCB fabrication, and how to avoid them?

1. Overlap of welding plates.

a. Create heavy holes, which are broken and damaged by multiple boreholes in one place during drilling.

b. In the multilayer PCB board, both connection plates and isolation plates are at the same position. Therefore, the PCB board is shown as isolation and connection error.

2. The use of graphics layer is not standard

a. The violation of conventional design, such as component surface design at the bottom layer and welding surface design at the TOP layer, is misleading.

b. There is a lot of design garbage on each layer, such as broken lines, useless borders, labels, etc.

3. Unreasonable characters

A. Characters covering the SMD welding sheet will inconvenience PCB on-off detection and component welding.

b. The characters are too small to make screen printing difficult, and the characters are too large to overlap, making it difficult to distinguish. The fonts are generally >40mil.

4. Set the aperture of a single welding plate

a. The single-side welding plate generally does not have boreholes, and its aperture should be designed to be zero; otherwise, when borehole data is generated, the coordinates of holes will appear at this position. Special instructions should be given for drilling holes.

b. If the single-side bonding pad needs to be drilled, but the aperture is not designed, the software will treat the bonding pad as an SMT bonding pad during the electricity and formation data output. As a result, the isolation plate will be lost in the inner layer.

What files are sent to the PCB fabrication factory?

If you want to get the PCB fabrication cost, you must send the PCB specification to the PCB fabrication factory. If you need PCB fabrication, please send the original PCB files such as (flies.pcb, flie.docpcb) or Gerber files and PCB fabrication drawing notes to the PCB fabrication factory.

PCB fabrication drawing notes should specify the number of PCB fabrication, the thickness of PCB, the thickness of copper, the color of PCB, surface treatment, how to PCB assemble copy, how to deliver, the required delivery date, etc.

If you do not have PCB fab notes example, ipcb has prepared a PCB fab drawing instance for you; please click to download the PCB fabrication notes example - ![]() PCB fab notes example.

PCB fab notes example.

IPCB has passed ISO9001, UL, RoHS, and other quality management system certifications. Our fabrication line adopts imported precision circuit board fabrication and testing equipment, has a senior PCB fabrication technical team and has formed a perfect assurance system and strict quality management. PCB is manufactured strictly according to ipcb Level 2 standard or IPC Level 3 standard to ensure that PCB meets customer quality requirements. In addition, the company advocates the PCB quality concept of "doing our best and focusing on prevention," which improves the efficiency of PCB fabrication, saves cost and working time, and provides customers with the best PCB fabrication service.

IPCB is a PCB fabrication professional manufacturer; you can request a PCB fabrication quotation here. Please contact ipcb or send Gerber files and PCB fabrication drawing notes to ipcb. We'll get back to you soon.