What is Boiler PCB? Boiler pcbs play a crucial role in modern heating systems. Whether for industrial boilers or household water heating systems, the boiler Printed Circuit Board serves as the central control unit, managing heating elements, temperature sensors, and safety switches. The design and manufacturing quality of a boiler Printed Circuit Board directly impact the system's stability and efficiency, making the choice of a high-quality PCB essential for the overall system performance.

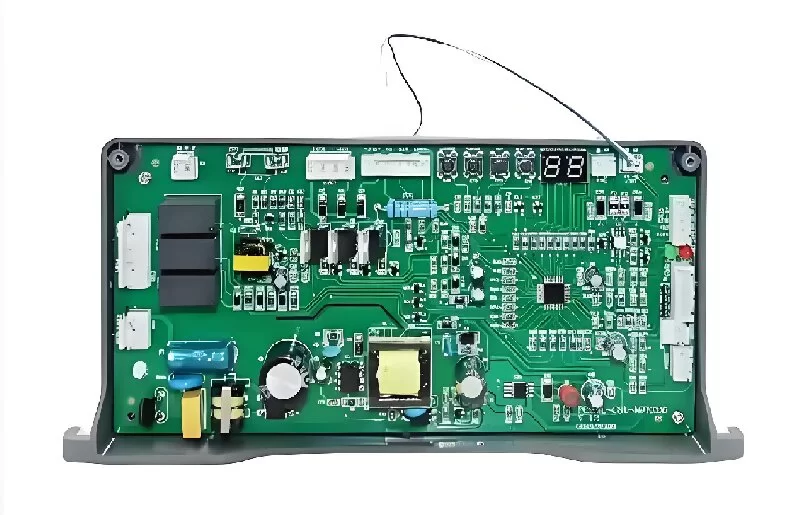

Boiler PCBs typically consist of power circuits, control assemblies, connectors and other electronic components, all of which are precisely laid out on the board to ensure rapid signaling and reliability. In addition, good material selection and manufacturing processes have a great impact on the performance of boiler PCBs.

Boiler pcb is critical in ensuring the stability and safety of heating systems. As the control center, it manages the operation of the boiler, including temperature regulation, power-on and shutdown sequences, and other essential functions. Modern boiler Printed Circuit Boards are often equipped with microcontroller technology, enabling smarter operation and self-diagnosis capabilities. During the operation of a boiler, the PCB can monitor temperature, pressure, and fuel consumption, ensuring that the device operates at optimal performance levels while preventing any potential hazards from occurring.Boiler Printed Circuit Board design needs to ensure durability, especially in extreme temperature conditions. Given the high-temperature environment in which boilers typically operate, the PCB materials must possess excellent heat resistance. High-quality FR4 materials are commonly used in boiler Printed Circuit Boards to guarantee functionality even in harsh conditions. Additionally, the PCB must resist corrosion caused by steam and other chemical substances produced during boiler operation. By employing precision circuit design and selecting the right materials, boiler Printed Circuit Boards maintain their reliability and stability over long periods of use.

Boiler pcb

Boiler pcbplay a significant role in energy efficiency, an increasingly important factor in modern boiler design. The PCB enables precise control of temperature and power regulation, which helps minimize energy waste. For example, boiler Printed Circuit Boards can use intelligent algorithms to analyze indoor temperature and adjust heating power accordingly, preventing over-heating. This not only saves energy but also extends the lifespan of the boiler. As smart home systems become more widespread, many boiler Printed Circuit Boards now support remote monitoring and control, allowing users to adjust temperature settings in real-time via smartphone applications.Manufacturing boiler Printed Circuit Boards also involves adhering to strict industry standards. In addition to regular PCB manufacturing requirements, boiler Printed Circuit Boards undergo additional quality control measures such as high-temperature resistance testing and electrical safety checks to ensure they function safely and reliably across various operating conditions.Moreover,modern boiler Printed Circuit Boards often come with built-in self-diagnosis features. When a fault occurs in the system,the PCB can detect the issue and alert users,helping prevent larger problems and reducing the need for costly repairs.

Boiler pcb are designed with robustness in mind,given the challenging environments in which they operate.They need to withstand both the physical stress and electrical demands of the heating system, ensuring reliable performance over time.In this context, ongoing advancements in PCB technology have introduced solutions for improving thermal management and reducing the risk of overheating. Techniques like optimized layer stacking and improved copper routing are often utilized in boiler Printed Circuit Board design to enhance current distribution and minimize resistance.These innovations, in combination with advanced protective coatings, ensure that the boiler Printed Circuit Board maintains its functionality in even the most demanding applications.With the integration of IoT (Internet of Things) into home and industrial systems, boiler Printed Circuit Boards are now at the forefront of smart control technologies. The PCB can communicate with other devices in the network, providing real-time data on energy consumption, operational status, and system diagnostics. This connectivity makes it easier for technicians to perform preventive maintenance and for users to optimize energy use based on specific heating demands. The integration of wireless modules and cloud-based services further enhances the functionality of boiler Printed Circuit Boards, bringing heating systems into the realm of smart living.

The evolving standards for environmental responsibility are also reflected in boiler Printed Circuit Board design. Manufacturers are increasingly focusing on using recyclable and eco-friendly materials. In addition, boiler Printed Circuit Boards are now designed to be more energy-efficient than ever before, reducing the environmental footprint of heating systems. By optimizing energy usage and employing sustainable materials, the impact of these PCBs on the environment is minimized, in line with global initiatives to combat climate change. Energy-efficient boilers, combined with these innovative PCBs, are increasingly becoming a selling point for consumers conscious of both performance and sustainability.

Boiler pcb serve as the control hub for heating systems, tasked with improving efficiency, reducing energy consumption, and ensuring safety. By leveraging advanced circuit design and high-quality materials, modern boiler Printed Circuit Boards have become an indispensable part of heating systems. Whether through smart control or enhanced durability, boiler Printed Circuit Boards continue to push the technological frontier, providing households and industries with more reliable and efficient heating solutions.