Rogers PCBs are primarily used in high-frequency circuit applications and are highly sought after for their excellent electrical performance and stable material properties. Price-wise, Rogers PCB price varies depending on a number of factors and cover a range from a few dollars to tens of dollars per unit.

Depending on the manufacturer and product specification,the price range of Rogers PCBs typically ranges from approximately ¥2.00 to ¥36.55 per unit. For example, certain high-frequency materials such as the RO4350 and RO3000 series can be relatively expensive, typically ranging from ¥3,000 to ¥6,000 per square meter. This indicates that users need to choose according to their actual needs and budget when purchasing.

Influencing factors of Rogers pcb price:

1.Material Selection

The material composition and structure of Rogers circuit boards directly affects their performance and quality, which in turn affects the price. Different types of materials have different costs, the choice of materials is one of the key factors in determining the price of the circuit board.

2. Production process

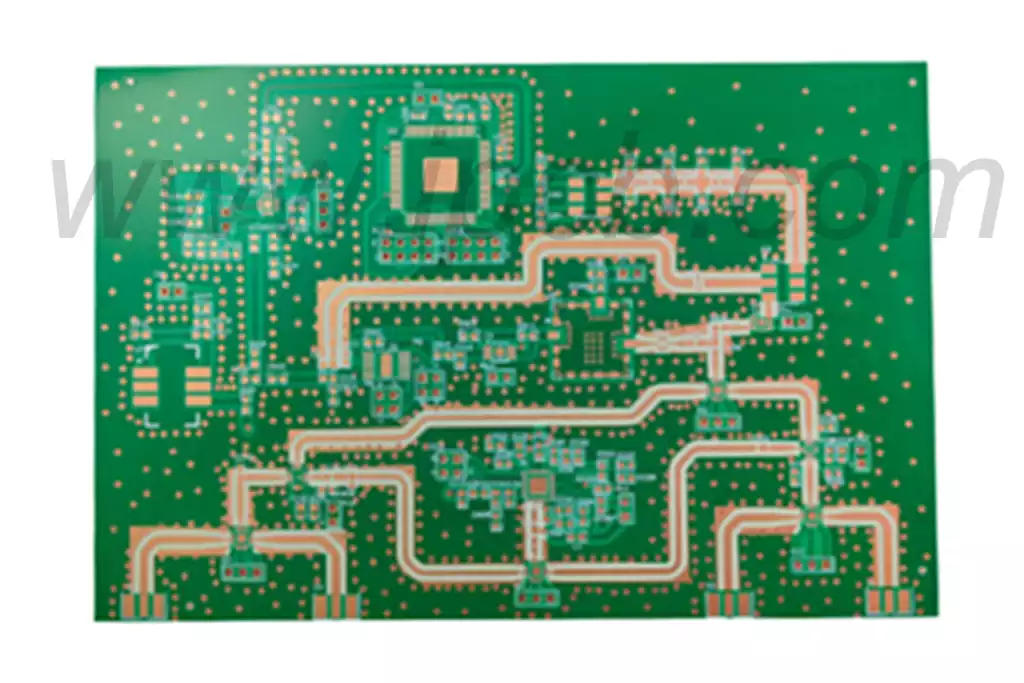

The rigor of the production process is also an important factor affecting the price of Rogers PCB. Complex production processes and high precision manufacturing requirements usually mean higher production costs, which will be reflected in the final price.

The complexity of the production process is one of the primary factors affecting price.Complex processes usually involve more material usage,equipment requirements, and worker skills, which increase production costs.For example,a manufacturing process that uses multi-layer boards and high precision drilling tends to increase the price significantly because it requires higher skills and longer production times .

3.Design Complexity

The design complexity of the product also affects the price.Factors such as the number of layers, board thickness, and circuit layout design will increase the difficulty and cost of manufacturing,thus affecting the price.

4.Order quantity

The number and size of the order is directly related to the degree of price concessions.Typically, large purchases can get a lower unit price, while small orders may face higher unit costs.

5.Market demand

Fluctuations in market demand can lead to changes in prices. When demand increases, prices usually rise; conversely, when demand decreases, prices may fall. This is especially true during peak periods in the industry.

6.Regulatory and environmental requirements

The applicability of laws and regulations to the materials selected,such as compliance with environmental requirements such as RoHS and halogen-free, also affects the price. Consequently, materials that comply with the relevant laws and regulations usually come at an additional cost.

Rogers PCBs are the material of choice for high-frequency circuit applications due to their excellent electrical properties,yet Rogers pcb price fluctuations are influenced by a variety of factors. A number of aspects such as material selection, complexity of the manufacturing process, design requirements,order size, market demand, and laws and regulations all combine to determine the final cost of the board.