Rogers 5880 thicknesses range from 0.2 mm to 4.8 mm and include several standard thickness options such as 0.127 mm, 0.254 mm, 0.381 mm, 0.508 mm, 0.787 mm, 1.575 mm and 3.175 mm. This flexibility in thickness options makes the Rogers 5880 suitable for a wide range of circuit design needs and capable of meeting a variety of high frequency circuit requirements.

Common thickness applications include:

0.254mm (10mil): suitable for most standard PCB designs.

0.508mm (20mil): Widely used for high frequency circuits requiring high structural strength and low signal loss.

0.762mm (30mil): Suitable for the needs of circuits with high power or more complex circuit designs.

When selecting thickness, designers consider factors such as the material's electrical properties,mechanical strength,and process method to ensure that specific engineering needs are met.

Considerations when choosing the thickness of Rogers 5880 material

1.Electrical Properties

Electrical properties are one of the primary considerations when selecting material thickness.The dielectric constant (Dk) of Rogers 5880 helps reduce delay and loss in signal propagation. Thinner materials typically reduce signal delay and improve signal transmission efficiency,especially important in high frequency applications.

2.Mechanical Strength

Mechanical strength is also an important factor in thickness selection.In some applications,especially those that require the board to withstand physical stress or environmental challenges, thicker materials provide better mechanical support and stability.This is especially critical for applications in high temperature,high humidity or vacuum environments.

3.Manufacturing and Processing Requirements

Different thicknesses may place different demands on manufacturing and processing.Thicker materials may require higher machining accuracy and more complex processes,while thinner materials may be easier to machine and print.Therefore,these manufacturing requirements need to be taken into account at the design stage to ensure a smooth production process.

4.Cost Factors

The thickness of the material has a direct impact on the cost,with thicker materials usually being more expensive.Designers need to weigh the performance requirements against the budget to select the most cost-effective material thickness.Considering the overall design requirements and the production budget,rational planning of material procurement will help to control costs.

5.Environmental and Application Characteristics

Selection of thickness should also consider the specific application of environmental conditions, such as temperature, humidity and electromagnetic interference and other factors. Different thicknesses of materials in different environments may be different, so engineers should be based on the needs of the actual application, select the appropriate thickness to ensure the reliability and stability of the material!

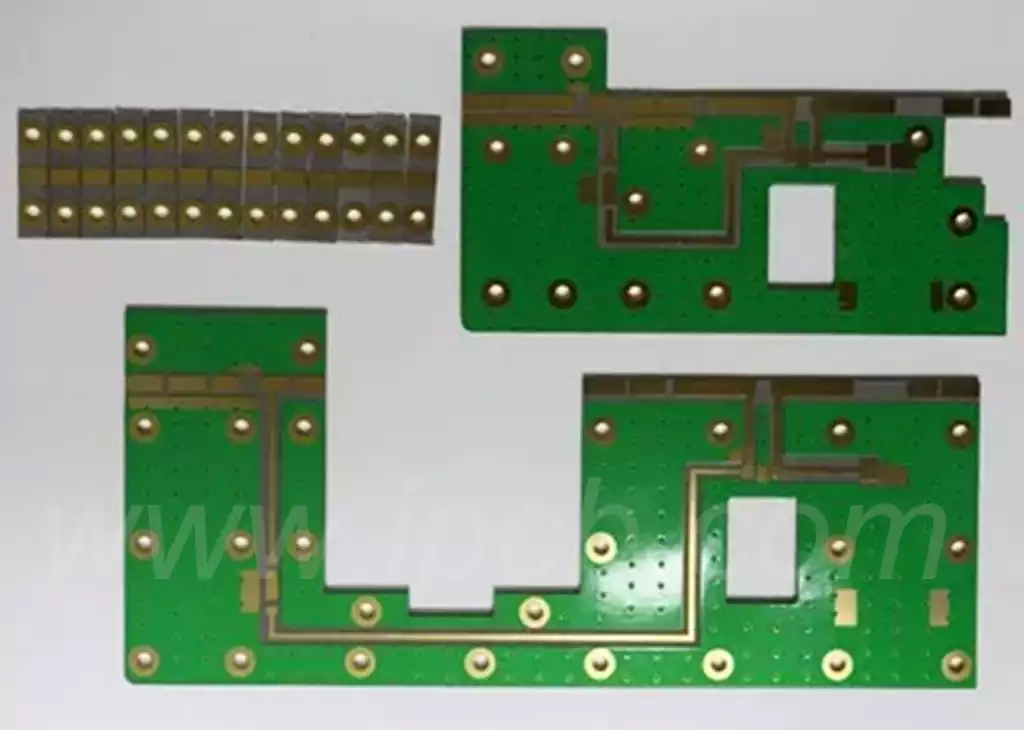

rogers 5880

Effect of Rogers 5880 material thicknesson signal transmission

1.Signal delay

The thickness of the material directly affects the propagation speed of the signal in the circuit board.Thinner circuit boards can significantly reduce the signal delay and increase the speed of signal propagation, which is due to the thinner material in the dielectric effect is smaller, thus reducing the loss of signal propagation .Specifically,the Rogers 5880's low dielectric constant (Dk of 2.2) further enhances this effect,resulting in superior performance in high frequency applications.

2.Signal Integrity

The thinner Rogers 5880 material helps improve signal integrity by reducing dielectric effects.Thicker materials can lead to higher signal loss,increased signal reflection and distortion,which can negatively impact high frequency signals. Studies have shown that thin circuit boards typically exhibit better signal transmission characteristics at higher frequencies .

3.Signal Loss

The choice of thickness also affects the loss characteristics of the material.Thinner boards reduce signal loss,which is essential to ensure high signal quality at high transmission speeds. On the contrary,thicker boards,while enhancing mechanical strength,may lead to capacitive coupling and higher signal loss during high frequency operation.

4.Mechanical Properties and Temperature Stability

While thinner materials have advantages in signal transmission,increased thickness can improve the mechanical properties and thermal stability of the board.Thicker materials provide better stability in high temperature or high humidity environments,which is critical for many application scenarios such as aerospace and military.Therefore,when selecting material thickness, designers need to consider the trade-off between signal performance and mechanical properties.

5.Manufacturing Considerations

Thinner materials may face more challenges in handling and manufacturing, including higher processing difficulty and cost.Therefore,when designing circuits, designers should not only consider the signaling performance,but also evaluate the feasibility and economics of the manufacturing process .

Choosing the right thickness of Rogers 5880 is critical to high frequency circuit design.Designers should not only focus on the electrical properties and signal transmission quality of the material, but also consider mechanical strength, manufacturing process,cost,and environmental factors. By thoughtfully selecting the right thickness, you can ensure efficient performance and reliability of your circuits in a variety of application scenarios.