RT Duroid 6010 is renowned in the PCB industry as a high-frequency, low-loss microwave substrate that plays a pivotal role in designing and manufacturing advanced circuit boards. Its unique properties make it particularly suitable for high-frequency applications, where performance and reliability are crucial. The substrate’s excellent electrical and thermal properties are attributed to its composition, primarily comprising polytetrafluoroethylene (PTFE) filled with ceramic particles. This combination results in a material that excels in high-frequency signal transmission, providing stability and reducing signal loss, which is essential for applications in RF, microwave circuits, and beyond.

This material 's most significant advantage lies in its stable dielectric constant, typically around 10.2, which remains consistent across a wide frequency range. This stability ensures that signals maintain their integrity during transmission, which is especially critical in high-frequency designs. The material's low dielectric loss factor further minimizes energy dissipation, allowing for efficient signal transmission with minimal attenuation. This makes This materiala preferred choice for critical applications such as satellite communications, radar systems, and high-frequency antennas, where maintaining signal fidelity is of utmost importance.

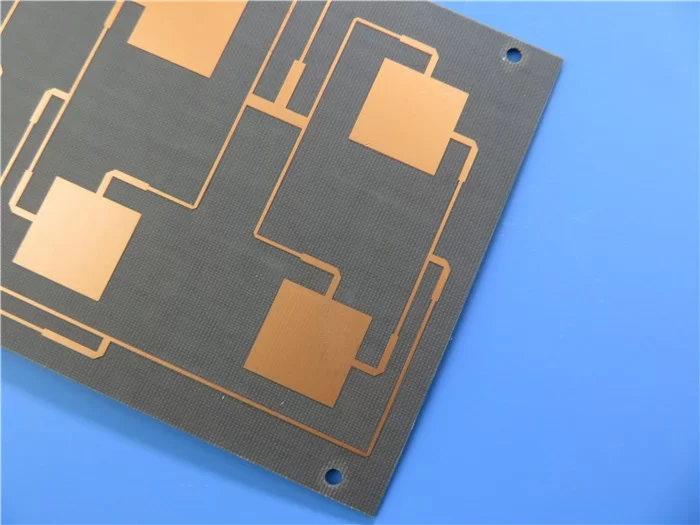

RT Duroid 6010

RT Duroid 6010 also exhibits excellent thermal management capabilities, which is a crucial factor in high-power applications. The material's low thermal coefficient of dielectric constant (TCDk) means that its performance remains stable even under varying temperature conditions, making it suitable for use in environments with extreme temperature fluctuations. This thermal stability, combined with its high thermal conductivity, ensures that heat is effectively dissipated, reducing the risk of thermal-induced failures. In aerospace and military applications, where components are often subjected to harsh environmental conditions, the reliability of This materialbecomes a critical asset.This material requires specialized handling and processing techniques due to its unique material properties. The rigidity and brittleness of the substrate necessitate precision in manufacturing processes such as cutting, drilling, and etching. Conventional mechanical drilling can lead to microcracks or delamination, which compromise the board's integrity. Therefore, advanced techniques like laser cutting or controlled-depth routing are often employed to achieve clean, precise cuts without damaging the substrate. Additionally, special considerations are needed for surface treatments to ensure optimal adhesion of copper layers and other conductive materials, which are vital for maintaining the board's electrical performance.

RT Duroid 6010 is also known for its versatility in various applications beyond RF and microwave circuits. It is widely used in electromagnetic compatibility (EMC) and electromagnetic interference (EMI) shielding, where its high dielectric constant and low loss factor provide effective insulation and shielding capabilities. This makes it an ideal choice for applications in modern communication devices, such as smartphones and tablets, where minimizing electromagnetic interference is critical to ensure optimal performance. Furthermore, the material's inherent properties make it suitable for use in filters, couplers, and other passive components that require precise control over signal propagation characteristics.This materialhas gained a strong foothold in the development of next-generation communication technologies, including 5G networks and advanced radar systems. Its high-frequency performance and reliable dielectric properties make it a key enabler of these technologies, which demand high-speed data transmission and minimal signal degradation. In 5G infrastructure, for example, This materialis used in base station antennas and other critical components that require stable, high-frequency operation. As the demand for high-speed, high-frequency communication continues to grow, the role of This materialin supporting these advancements is expected to expand.

RT Duroid 6010 's impact extends to the automotive industry as well, where it is used in advanced driver-assistance systems (ADAS), collision avoidance systems, and vehicle-to-everything (V2X) communication. These applications require highly reliable and high-frequency PCB substrates to ensure safe and efficient operation. The material's ability to maintain performance under dynamic conditions, such as changes in temperature and environmental stress, makes it a reliable choice for these critical automotive systems. As the automotive industry moves towards greater connectivity and automation, the use of This materialin these applications is likely to increase.This materialhas established itself as a critical material in the high-frequency PCB market due to its unique combination of properties, including stable dielectric constants, low loss factors, and excellent thermal management capabilities. As industries continue to push the boundaries of high-frequency applications, the demand for materials like This materialthat can deliver consistent and reliable performance will only grow. Its role in supporting emerging technologies, from 5G to autonomous vehicles and beyond, underscores its importance as a foundational material for the future of electronic design.

RT Duroid 6010 will continue to be a cornerstone material in the evolution of high-frequency PCB technology. Its unique properties, combined with its adaptability to various applications and manufacturing processes, position it as a critical component in the advancement of modern electronics. As engineers and designers continue to explore new frontiers in high-frequency applications, This materialwill undoubtedly play a key role in shaping the future of electronic design and manufacturing.