The practice of testing PCB boards is not just a single-step process but a multi-faceted approach that includes various stages and methodologies to ensure that each board meets the highest standards of quality. In today's fast-paced electronics industry, where devices are becoming more compact and feature-rich, the demand for more sophisticated and reliable PCBs has never been higher. This has led to an increased focus on the testing processes to ensure that every PCB board can withstand the demands of its intended application.

Testing PCB boardsis the initial design review. Before any physical testing can take place, the design of the PCB is scrutinized to ensure that it adheres to industry standards and best practices. This includes checking the layout, routing, and component placement to ensure that the board can be manufactured without issues. The design review process also involves simulations to predict how the PCB will perform under various conditions. These simulations are crucial because they can identify potential problems that may not be apparent during physical testing.Once the design has been approved, the next step in Testing printed circuit boards is to create prototypes. These prototypes are subjected to a battery of tests to verify their functionality. The prototype stage is critical because it allows engineers to catch any issues before the design goes into full-scale production. During this stage, engineers use various testing methods such as thermal cycling, vibration testing, and electrical stress testing to push the PCB to its limits. These tests help ensure that the board can handle the harsh environments it may encounter in real-world applications.

Testing PCB boards

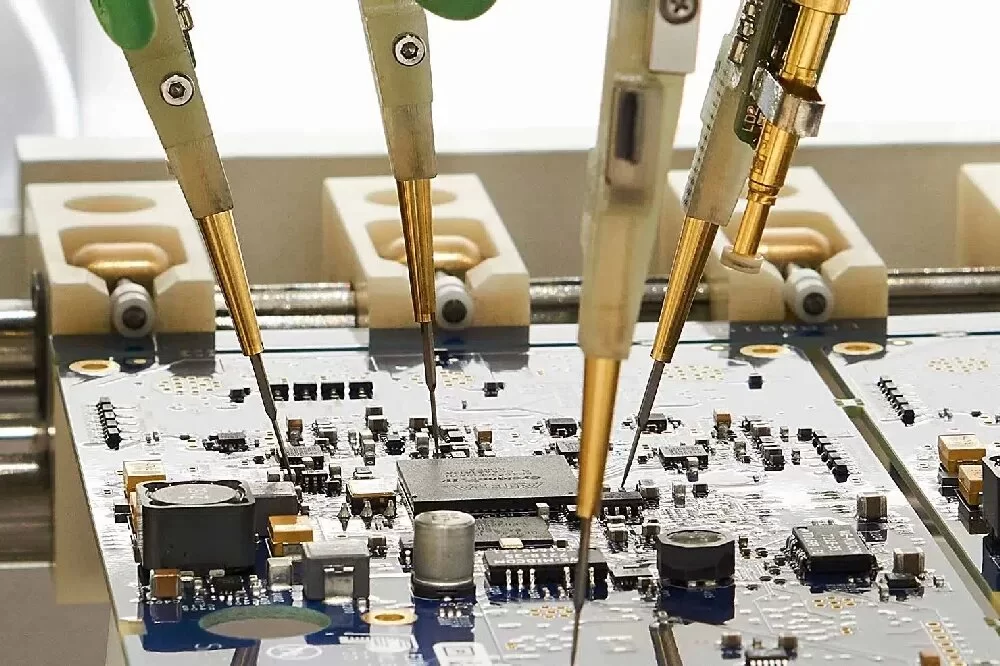

After the prototype stage, the focus shifts to production-level testing. In mass production, Testing printed circuit boards becomes even more critical because any defects can result in significant financial losses. Manufacturers use automated testing equipment to quickly and accurately test each PCB board as it comes off the production line. These tests include In-Circuit Testing (ICT), which checks the electrical performance of each component on the PCB, and Flying Probe Testing, which uses robotic probes to test the connections on the board without the need for test fixtures. These automated tests are essential for maintaining high production throughput while ensuring that every board meets the required quality standards.

Testing PCB boardsalso involves environmental testing, where boards are subjected to extreme temperatures, humidity, and other environmental factors to ensure they can withstand the conditions they will face in the field. This type of testing is especially important for PCBs used in automotive, aerospace, and military applications, where the boards must perform reliably in harsh environments. Environmental testing can include thermal shock testing, where the PCB is rapidly cycled between high and low temperatures, and salt spray testing, which simulates the corrosive effects of saltwater on the board's components and connections.In addition to the physical and environmental tests, Testing printed circuit boards also involves reliability testing, where boards are subjected to extended use under normal operating conditions to determine their lifespan. This type of testing is crucial for identifying potential failure points that may not be apparent during shorter testing cycles. Reliability testing can include burn-in testing, where the PCB is operated at elevated temperatures for an extended period to accelerate the aging process, and Highly Accelerated Life Testing (HALT), which subjects the board to extreme stress conditions to identify its limits.

As the electronics industry continues to evolve, the methodologies used for Testing printed circuit boards are also advancing. Manufacturers are increasingly turning to advanced testing techniques such as 3D X-ray imaging, which allows engineers to see inside the PCB and inspect the quality of solder joints and connections. This type of testing is especially useful for detecting defects in high-density and multilayer PCBs, where traditional testing methods may not be sufficient.

Testing PCB boards is the use of artificial intelligence (AI) and machine learning (ML) to analyze test data and identify patterns that may indicate potential defects is an another emerging trend. These technologies can help manufacturers improve their testing processes by identifying issues earlier in the production cycle, reducing the likelihood of defects making it through to the final product. AI and ML can also be used to optimize testing procedures by analyzing data from previous tests and adjusting the testing parameters to focus on areas that are more likely to have issues.The importance of Testing printed circuit boards cannot be overstated. As electronic devices become more complex and the demand for high-quality products increases, manufacturers must continue to invest in advanced testing methodologies to ensure that their PCBs meet the required standards. By doing so, they can reduce the risk of defects, improve product reliability, and ultimately enhance customer satisfaction.

In summary, Testing PCB boards is a multifaceted process that involves a combination of design review, prototype testing, production-level testing, environmental testing, and reliability testing. Each of these stages is critical to ensuring that the final product meets the highest standards of quality and reliability. As the industry continues to evolve, manufacturers must continue to innovate and adopt new testing methodologies to stay ahead of the competition and meet the demands of their customers.