Chip probes is an indispensable tool used to test the electrical performance of integrated circuits (ICs) and printed circuit boards (PCBs). As electronic devices become smaller and more integrated, chip probe technology has also advanced, providing reliable solutions for testing complex circuits. This article will explore the principles of IC probes, their application in PCB production, and their importance in the electronics manufacturing industry.

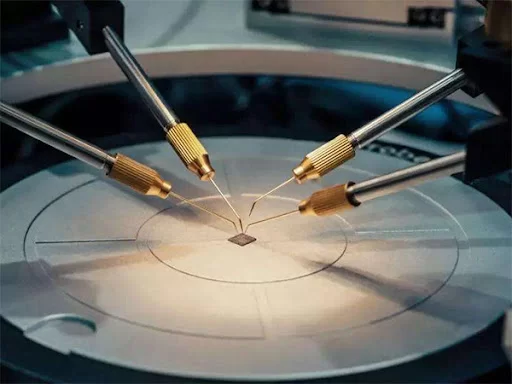

Chip probes are typically composed of extremely fine metal needles that, through precise positioning, make contact with specific test points on an IC or PCB. IC probes can be used to measure voltages, currents, and signal integrity within the circuit, ensuring that each chip and PCB functions according to design specifications.During the manufacturing process, IC probes are essential for not only detecting the electrical characteristics of circuit boards but also identifying potential manufacturing defects early on. These probes can quickly scan each critical point on a circuit board, ensuring that every PCB undergoes strict quality control before leaving the factory.

The precision and versatility of IC probes have led to their widespread use in PCB design and production. Whether in the research and development phase for prototype testing or in mass production for quality control, IC probes provide manufacturers with reliable data support. As the complexity of electronic products increases, with the growing use of multi-layer PCBs and high-density packaging, chip probe technology is becoming a key tool to ensure the proper functioning of these complex designs.

Chip probes

When using Chip probes. The accuracy of the probe tips directly impacts test results, regular maintenance and calibration are crucial. So regular inspection and replacement of worn probe tips ensure testing accuracy. Additionally, as testing technology advances, the integration of automated testing systems with chip probe technology is becoming more common, further enhancing testing efficiency and reliability.Despite the many advantages of chip probe technology, it also faces challenges. For instance, as chip sizes decrease and packaging density increases, the tiny size and positioning precision required of the probe tips are becoming more demanding. This places higher requirements on probe manufacturing processes and testing equipment. Furthermore, excessive contact and pressure in some cases may damage the chip or circuit board, so careful handling is required when using probes.

The IC probes also plays a vital role in advanced testing environments, such as those required for high-frequency or high-speed circuits. As electronic devices push the limits of performance, maintaining signal integrity becomes paramount. IC probes are engineered to minimize signal loss and interference, making them ideal for testing circuits that operate at gigahertz frequencies or those with high-speed data transmission requirements.

Chip probes is essential in the testing and development of new semiconductor technologies. As semiconductor devices continue to shrink and new materials are introduced, the need for precise, non-invasive testing methods grows. IC probes offer the ability to access the minute features of advanced semiconductors without damaging them, providing invaluable data that drives innovation in the industry.One of the emerging applications of IC probes is in the field of flexible electronics. As wearable technology and flexible displays gain popularity, the PCBs and ICs used in these devices must also be flexible. IC probes are being adapted to test these flexible circuits, ensuring that they maintain their integrity and performance even when bent or stretched. This adaptation of chip probe technology is critical for the continued development and commercialization of flexible electronics.Additionally, IC probes are becoming increasingly automated, with advancements in robotic systems allowing for more precise and efficient testing. Automated systems can position IC probes with micrometer precision, significantly reducing the time required for testing and increasing the throughput of PCB production lines. This automation not only enhances productivity but also reduces the potential for human error, leading to more consistent and reliable test results.

In conclusion, Chip probes play a critical role in modern PCB design and production. They provide efficient and reliable means for testing and verifying complex circuits, helping manufacturers improve product quality and reduce production costs. As technology continues to evolve, the application of IC probes will expand further, playing an increasingly important role in the electronics manufacturing industry.