PCB solder mask material plays a crucial role in PCB design and production. Solder masks not only protect the circuit board from contamination and oxidation but also prevent circuit short circuits, enhancing the overall performance and reliability of the PCB.

PCB solder mask materials can be broadly classified into the following categories:

1. Liquid Photoimageable (LPI): This material is cured through photochemical reactions and is widely used in the PCB industry. It offers high resolution, excellent chemical resistance, and mechanical strength.

2. Thermosetting Ink: This material is cured through heat treatment and is suitable for PCBs used in high-temperature environments. It has high thermal resistance and mechanical strength but relatively low resolution.

3. Inkjet Printing Materials: This material is applied to the PCB surface using inkjet printing technology, making it ideal for rapid prototyping and small-scale production. It offers high flexibility and cost-effectiveness.

4. Thermoplastic Ink: This material is melted and cured by heating, mainly used for low-cost PCB applications. It has lower thermal resistance and mechanical strength but is inexpensive.

PCB solder mask materials have wide applications in PCB design:

1. Circuit Protection: Solder mask materials protect the conductive traces on the PCB surface from corrosion and oxidation caused by environmental factors, enhancing the durability and reliability of the circuit board.

2. Short Circuit Prevention: By covering areas that do not require soldering, solder mask materials effectively prevent solder bridging and short circuits, ensuring proper circuit operation.

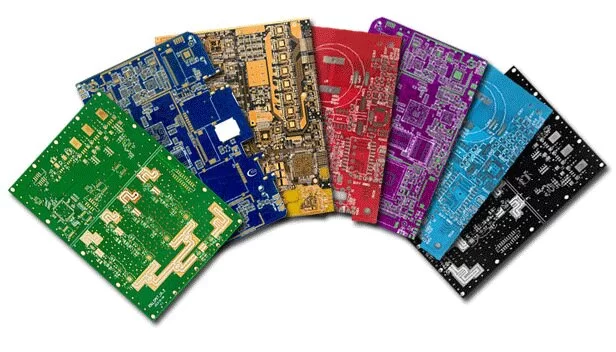

3. Identification Function: Solder mask materials typically have colors and markings that help technicians quickly identify and locate circuit components, facilitating maintenance and repair.

4. Aesthetic and Cleanliness: Solder mask materials make the PCB surface more aesthetically pleasing and clean, improving the overall quality and market competitiveness of the product.

PCB solder mask materials

Different types of PCB solder mask materials have distinct characteristics:

1.Liquid Photoimageable:

Advantages: High resolution, suitable for complex circuit designs; excellent chemical and mechanical resistance; ideal for large-scale production.

Disadvantages: Some environmental and safety risks; requires specialized equipment and processes.

2.Thermosetting Ink:

Advantages: High thermal resistance, suitable for high-temperature environments; good mechanical strength.

Disadvantages: Relatively low resolution; longer curing time.

3.Inkjet Printing Materials:

Advantages: High flexibility, suitable for rapid prototyping and small-scale production; cost-effective.

Disadvantages: Lower chemical and mechanical resistance; not as high resolution as LPI.

4.Thermoplastic Ink:

Advantages: Inexpensive, suitable for low-cost applications; easy to use.

Disadvantages: Lower thermal and mechanical strength; not suitable for high-precision circuit designs.

The solder mask materials are also crucial in PCB production:

1.Improving Production Efficiency: By using automated equipment and precision processes, the application of solder mask materials can significantly improve PCB production efficiency and yield, reducing production costs.

2. Ensuring Quality Stability: High-quality solder mask materials ensure the quality stability of each PCB, reducing the scrap rate and rework rate in the production process.

3. Meeting Various Process Requirements: Different types of solder mask materials can meet the requirements of different production processes and application environments, enhancing the adaptability and diversity of PCB products.

4. Environmental Protection and Safety: Choosing environmentally friendly solder mask materials and safe production processes can reduce environmental pollution and ensure the health and safety of operators.

With the continuous advancement of technology, the solder mask materials are also evolving. In the future, with the application of new materials and technologies, solder mask materials will become more efficient and environmentally friendly. For example, the use of nanomaterials can significantly improve the performance of solder masks, reducing their thickness and weight; the development of green and environmentally friendly materials can reduce environmental impact and meet the requirements of sustainable development.

PCB solder mask materials play an important role in PCB design and production. By understanding the characteristics and applications of different types of solder mask materials, engineers and technicians can choose the most suitable materials, optimize PCB design and production processes, and improve product quality and reliability. In the future, with the continuous advancement of technology, solder mask materials will witness more innovations and developments, providing more possibilities for the electronics industry.