The relative permittivity of copper plays a crucial role in the design and production of printed circuit boards (PCBs). While copper itself is a conductive material and its relative permittivity is generally considered to be infinite, the dielectric properties of copper significantly impact the electrical performance of PCBs in practical applications. This article will explore the relative permittivity, its importance, effects, and applications in PCB design and production.

Before delving into the relative permittivity of copper, it's essential to understand the concept of copper permittivity.Permittivity,also known as the dielectric constant, measures a material's ability to store electrical energy in an electric field.Relative permittivity is the permittivity of a material relative to the permittivity of a vacuum,which is assigned a value of 1. Most insulating materials have a relative permittivity between 2 and 10,while conductive materials like copper have a relative permittivity that can be considered infinite because they do not store energy in an electric field but instead conduct electricity.

The relative permittivity of copper directly affects signal transmission and electrical performance in PCB design and production.Copper is used as the conductive material for traces and pads on PCBs. Although copper permittivity is infinite, its surface resistance and conductive properties significantly influence signal integrity and transmission speed in high-frequency signal transmission. Specifically, the surface roughness and oxidation layer of copper can alter its electromagnetic properties, affecting signal propagation.

The relative permittivity impacts key parameters in PCB design, such as characteristic impedance and signal integrity. Characteristic impedance is a critical parameter in PCB design, determined by the geometry of the traces and the material properties. In high-frequency applications, the signal wavelength is comparable to the geometric dimensions of the traces, so any minor changes can lead to signal reflection and distortion. The conductive properties and surface condition of copper affect signal propagation speed and loss, thus impacting the characteristic impedance.

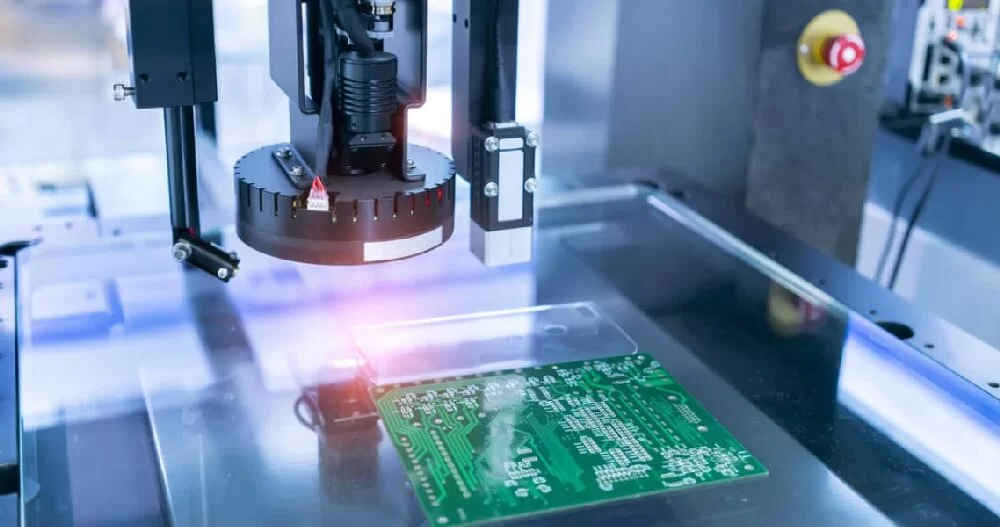

The relative permittivity of copper remains crucial during the production process.The purity, surface treatment, and thickness of the copper used in PCBs affect its conductive and electromagnetic properties.For example,the surface roughness of the copper layer can vary depending on the chemicals and process parameters used in electroplating, affecting signal transmission. In high-frequency applications,surface treatments like gold or silver plating can reduce surface resistance and improve signal transmission quality.

To optimize the impact of the dielectric properties of copper in PCB design and production, engineers and manufacturers must take several measures. First, precise calculation and simulation of characteristic impedance and signal integrity are necessary during the design phase to ensure the design meets high-frequency application requirements. Second, during production, strict control over the purity and surface treatment processes of copper is essential to ensure that the copper layer has excellent conductive and electromagnetic properties. Additionally, regular testing and verification of the PCB's electrical performance are necessary to ensure reliability and stability in practical applications.Furthermore, in multilayer PCB design, the dielectric properties also play a crucial role. In multilayer PCBs, the dielectric material between signal layers and power layers affects overall electrical performance. Although the copper layer itself has an infinite dielectric constant, its surface condition and thickness influence the capacitance and inductive coupling between signal layers. These factors impact signal propagation speed and loss. Therefore, in multilayer PCB design, engineers need to precisely control the thickness and surface condition of the copper layers to ensure consistent electrical characteristics between layers.

Overall, the relative permittivity of copper plays a key role in PCB design and production. Although it is theoretically infinite,its conductive properties and surface condition significantly affect high-frequency signal transmission and electrical performance. By optimizing design and production processes,the performance and reliability of circuit board can be effectively improved to meet the stringent requirements of modern electronic devices for high-frequency signal transmission and electrical performance.