Metal core pcb is to replace the epoxy glass cloth board with a metal plate of comparable thickness, after special treatment, so that the conductor circuits on both sides of the gold session of the board are connected to each other, and and the metal part is highly insulated. The advantage of the metal core printed board is heat dissipation and good dimensional stability, which is because aluminum, iron and other magnetic materials have a shielding effect, can prevent each other from interfering.

Layout and Structure of Metal Core PCB

Metal core printed board is the structure of the metal plate clamped into the printed board media layer, its structure can be various. Generally speaking, there are three kinds of structures: (1) the symmetrical structure of the metal core layout; (2) the asymmetrical structure of the layout; (3) the local structure of the layout.

Symmetrical structure of the metal core layout of the said “symmetrical” refers to the printed circuit board buried metal core on both sides of the structure or media thickness is the same.

In high-density and high-frequency PCBs, there are different levels of heat generation and temperature rise, so the number of layers and structure of the buried metal core can be different. Since most of the buried metal cores are in multilayer PCBs, there are multilayer symmetric metal core PCBs and single-layer metal core PCBs.

Note: The term “symmetrical” here refers to a structure that achieves a more balanced heat transfer within the PCB!

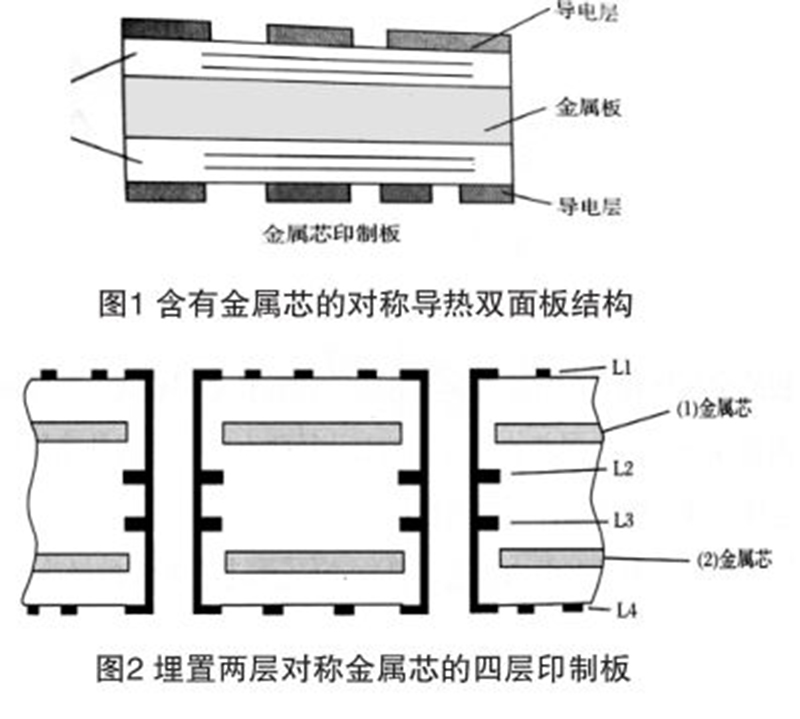

The symmetrical buried metal core structure is formed by sandwiching a metal core in a double-sided board, or by using a metal core copper-clad board, as shown in Figure 1. The use of this structure not only has high thermal conductivity, but more importantly has the advantages of small deformation, good flatness and high reliability, which is very advantageous for the installation or deployment of high-power components and high-density occasions!

Symmetrically buried metal core structure of the thermal conductivity of the multilayer board when the multilayer printed circuit board within the degree of temperature rise or heat generation is very high, but the degree of temperature rise in various places is the same or the difference is not very large, or due to the high-density, high-frequency and high-power occasions, but the temperature rise of the PCB as a whole is balanced, the structure of the symmetrically buried metal core can be used, and these structures are varied.

In the multilayer printed circuit board in high density or high frequency layout is more reasonable and uniform, although the overall heat is very high, but the overall PCB dielectric layer within the degree of high temperature is the same or close to the same. In this case and conditions, should be used multi-layer symmetrical thermal conductivity (metal core) structure, is conducive to balanced conduction of heat, so that the degree of temperature at each place of the PCB is more consistent, the temperature difference is small, so that the PCB at each place of the thermal internal stress is consistent. At the same time, can also make the PCB overall deformation degree of consistency, because the temperature difference is small, the PCB overall deformation difference is small. It is because of uniform heat dissipation, deformation is small, in order to help reduce the failure rate, improve reliability and service life! Figure 2 shows buried two layers of symmetrical metal core of the four-layer printed circuit board, that is, between L1 and L2, L3 and L4 to join the metal plate and form a symmetrical structure of the four-layer metal core printed circuit board, this structure can ensure that balanced conduction of heat inside the PCB, so that the temperature of the PCB inside the various parts of the PCB is relatively consistent, but also to achieve both reduce the temperature, but also to meet the deformation of the small requirements. If the temperature difference within the printed circuit board is still very large (especially between L2 and L3 temperature is high), can be added between L2 and L3 layer of metal core plate to solve the problem, the formation of a four-layer board with a three-layer metal core structure. If you can not meet the requirements to reduce temperature and deformation, and even between L2 and L3 metal core plate to increase the thickness (such as 1.25 times, 1.5 times and 2 times, etc.) to solve! When the PCB's high density and high frequency is not very high, or the degree of temperature rise within the PCB is not very high, but must use the metal core to reduce the heat, a layer of metal core can be used to achieve the purpose. Can be in Figure 1 only in the second layer (L2) and the third layer (L3) buried between a layer of metal core can be, due to the buried metal is in the center of the PCB structure, can achieve a balanced and symmetrical thermal conductivity effect!

By analogy, various types of printed laminates with good thermal conductivity and small deformation can be installed in six-layer boards, eight-layer boards, and so on, with heat-conducting metal core structures.

Asymmetrically buried metal core printed laminates due to high density, high frequency and component power, etc. in the PCB in each place in the deployment of different or large differences, will cause PCB each area of the temperature rise big difference, resulting in PCB each place in different dimensions of expansion and contraction, deformation state and internal stresses, etc. to affect the performance and reliability. But can be buried in different locations in the PCB cloth thermal conductivity of the metal core (piece, block, etc.) for thermal conductivity, the local high temperature lift down, so that the overall temperature of the PCB tends to be consistent, or PCB temperature difference is basically the same, can significantly improve the performance and reliability of the PCB!

PCB buried on one side of the structure of the metal core due to the side of the PCB (such as Figure 2 of the L1 and L2 with high-density, high-frequency or high-power device layout, so between L1 and L2 and L2 and L3 will be high thermal problems, while L3 and L4 between (due to the L3 and L4 is not high-density and high-frequency layout) will not occur high thermal phenomena, so can be between L3 and L4 without burying the Instead of burying a metal core heat-conducting structure between L3 and L4, a metal core heat-conducting structure can be buried between L1 and L2, and between L2 and L3. Thus forming an asymmetric buried metal core printed circuit board.

PCB local buried metal core structure due to a layer inside the PCB board or part of the surface layer (local) has a very high density, high-frequency or the surface of the installation of high-power components, which often results in local high heat phenomenon occurs, and therefore in the local PCB buried embedded in a metal plate (blocks, columns) to accelerate the heat transfer, reduce the local temperature, so that the overall temperature rise of the PCB is basically the same! The goal is to ensure that the PCB can be safe, reliable and long-life work!

In short, according to the PCB heat distribution and structural characteristics of the buried metal core, and decide to use the structure is symmetrical, asymmetrical and localized layout.

Advantages of metal core PCB:

In many aspects, LEDs are just like any other component installed on a circuit board. If only a few LEDs are present, such as green and red indicator lights for power on and off, there's nothing exceptional in arranging the PCB. However, there are lighting solutions that can keep LEDs or long arrays of LEDs on for long periods. Keeping these devices cool to prevent premature failure or safety hazards can be a major concern. Efficient cooling also requires ensuring consistent light output. Transitioning your PCB from standard FR4 types to MCPCB like aluminum PCBs is a worthwhile option. It uses specially formulated substrates to enhance the reliability of designs operating at tem

peratures above normal. The substrate is not strictly used as mounting surfaces for various components but actively absorbs heat from heat-running components to efficiently and safely dissipate heat into the relative layer of the circuit board. MCPCBs have proven to be an excellent solution for cooling PCBs with a large number of LEDs. Understanding the differences between standard epoxy glass boards and them is crucial.

Applications of metal core PCB:

LED Lighting: MCPCBs are usually suitable for applications that generate a significant amount of heat, where traditional fans cannot eliminate the heat efficiently. We often find MCPCBs in LED technology because they enable us to reduce the number of LEDs required for a certain amount of illumination and decrease the heat generated.

Automotive: Automotive power regulators, ignition, switch converters, variable optics, etc., all use metal PCBs. Power Equipment: Power converters, switching regulators, high-density power conversion.

Military and Aerospace: PCBs in military and aerospace applications must withstand extreme temperatures, thermal cycling, and moisture. Additionally, they must endure frequent mechanical shocks. Therefore, we use MCPCBs as they meet these service requirements and allow for higher structural integrity. Their high thermal conductivity ensures uniform temperature distribution on these boards. Thus, they can better withstand thermal cycling, preventing hotspots from forming near active components.

Metal core PCB

Comparison between metal core PCB and Standard PCBs:

Thermal Conductivity:Standard PCBs have a low thermal conductivity coefficient,typically around 0.3W, while MCPCBs have higher thermal conductivity, ranging from 1-2W.

Plated Through-Holes:Plated through-holes are often necessary in standard PCBs,but they may not be required in MCPCBs.

Heat Dissipation: Heat dissipation in standard PCBs often requires through-holes, leading to longer drilling cycles and additional processes. However, MCPCBs do not need drilling, plating, or deposition processes, as the metal core allows for effective heat dissipation.

Solder Mask:The solder mask layers in standard PCBs are usually dark-colored, such as black, green, blue, and red. Therefore, solder mask layers are applied on both the top and bottom in standard PCBs. In contrast, in MCPCBs,only the top is coated with a solder mask, which is typically white.

Thickness:Standard PCBs have a wide range of thicknesses due to layer stacking and various material combinations. However, the thickness variation in MCPCBs is usually limited due to available dielectric thicknesses and backing plate thicknesses.

Manufacturing Processes: Standard PCBs use traditional manufacturing processes such as routing, plated through-holes, drilling, and V-scoring. However, a diamond-coated saw blade is required to V-score MCPCBs because cutting metal requires sharp tools.

Things to consider for PCB manufacturers:

There are some handling considerations for MCPCB manufacturing, but as long as you understand how the material works and keep the design to a single-layer SMT type, designing your board shouldn't be much different than designing any other single-chip board , multi-layer PCB. If you find that you are unable to route your design to a single layer, please note that other MCPCB configurations are possible, although they are outside the scope of this article. These include:

2 layer PTH board with aluminum inside (this requires expensive pre-drilling/filling insulation/re-drilling steps to create plated through holes that won't short out).

A2 or more layer board manufactured according to standard PCB processes, but using thermal dielectric material instead of FR4 and laminating a metal backplane to the bottom for heat transfer.

When the design prioritizes cooling of multiple LEDs, MCPCB can be an excellent solution. They are becoming increasingly common in a variety of lighting applications - for homes, workplaces and vehicles. Although they are subject to certain design constraints, the manufacturing process is different from most other PCBs and is somewhat simpler.

Above is an introduction to metal core PCB.