Through hole soldering technology originated from Sony Corporation in Japan and was first applied in the early 1990s. However, it was primarily used for Sony's own products, such as TV tuners and CD Walkman.This technology employs point printing and point reflow methods, hence it is also known as the Spot Reflow Process, or spot solder reflow technology.

Through hole soldering is a common PCB manufacturing technique.It involves drilling holes in the PCB,inserting electronic components into them,and then using reflow soldering equipment to heat, solder,and cool these components,thus fixing them onto the PCB. Let's briefly understand the characteristics of through-hole reflow soldering:Through-hole insertion can achieve tighter circuit connections,higher assembly density,reduced interference between traces,and relatively lower manufacturing costs.

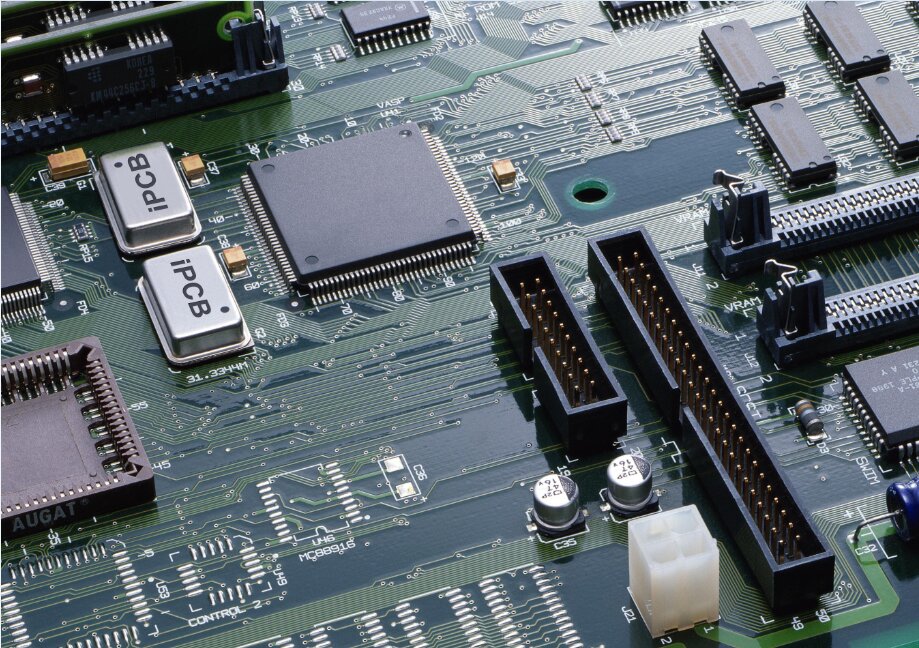

Through hole soldering

In the PCB assembly process, soldering through-hole components using reflow soldering technology is referred to as Through Hole Reflow (THR). This process involves using reflow soldering techniques to solder components with pins and irregular shapes.For products with a high number of surface mount technology (SMT) components and fewer through-hole components, this process can replace wave soldering and become a part of the PCB mixed assembly technology. The advantage of this process is the ability to achieve good mechanical joint strength while leveraging the benefits of surface mount manufacturing processes.

To address the inability of traditional reflow soldering to solder through-hole components, This technology overcomes many shortcomings of wave soldering, simplifies the process flow, and improves production efficiency. It is particularly suitable for soldering through-hole components in high-density PCBs. However, due to limitations such as pin length, pin end shape, and the volume of metal components in the solder paste, especially when using THR, calculating and controlling the amount of solder paste is complex. Therefore, THR may struggle to achieve over 100% solder penetration rate through the holes. Hence, for high-reliability PCBs, especially military products requiring connectors to withstand certain mechanical forces, THR should be used with caution. Compared to selective wave soldering, we prefer selective wave soldering, especially for gold-plated connectors, which has advantages that THR cannot match. Therefore, the main direction for the development of THR technology lies in process improvement and component enhancement, especially for high-reliability aerospace and military electronic equipment.

Through hole soldering also presents challenges.Through-hole reflow technology requires high-quality printing process parameters and solder paste quality. However, the filling condition of the solder paste inside the plated through-hole cannot be directly detected by solder paste inspection (SPI) equipment but can only be observed through X-ray. The lack of comprehensive online inspection of the through-hole filling rate is one of the reasons why the promotion of through-hole reflow soldering is relatively slow. The amount of solder paste largely determines the filling rate. However, due to variations in pins and reflow parameters, the volume of solder joints is mostly estimated rather than precisely calculated. To ensure an adequate amount of solder paste at plated through-holes, a stepped printing steel mesh can be used. This technique allows for selective increases or decreases in thickness in specific areas of the steel mesh to control the amount of solder paste in those areas. Optimal printing speed and angle often require numerical modeling for analysis. Additionally, the formula of the solder paste determines its wetting properties.Poor wetting properties make it difficult to fill the plated through-holes via capillary action.

Through hole soldering can replace wave soldering in many aspects,particularly when dealing with solder joints on components distributed densely on the soldering surface.Traditional wave soldering may struggle in such scenarios.Additionally,through-hole reflow soldering significantly improves soldering quality, which compensates for the high cost of equipment.The emergence of through-hole reflow soldering is helpful for enriching soldering methods,increasing PCB assembly density, enhancing soldering quality, and simplifying the process flow.

It can be foreseen that through hole soldering technology will play an increasingly important role in future electronic assembly.