Flex board is a printed circuit made of flex insulating substrate.Flex circuits provide excellent electrical performance,which can meet the design needs of smaller and higher-density installations,and also help reduce assembly processes and enhance reliability.

Flexboards are the only solution to meet the miniaturization and mobility requirements of electronic products. It can be freely bent, wound, and folded, and can withstand millions of dynamic bends without damaging the wires.It can be arranged according to spatial layout requirements,and can move and expand freely in three-dimensional space, achieving the integration of component assembly and wire connection.Flex circuit boards can greatly reduce the volume and weight of electronic products,making them suitable for the development of electronic products towards high density, miniaturization,and high reliability.

The characteristics of fpc boards

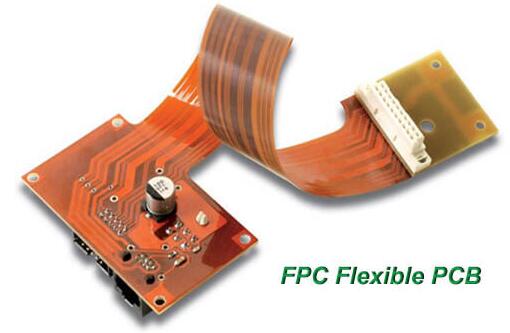

Flex pcb, also known as flex circuit board or flexible circuit board, abbreviated as flex board or FPC.It is a circuit board mainly composed of CU,acrylic,epoxy resin thermosetting adhesive, and PI. It has the advantages of high wiring density,lightweight,thin thickness,limited wiring space,and high flexibility.It is widely used in production and daily life,and the market is still expanding.

1. Reduce the volume of application products, save space, significantly reduce weight, increase effectiveness, and reduce costs.

2. Highly flexible, capable of three-dimensional wiring and changing shape according to space limitations.

3. Foldable without affecting signal transmission, or anti-static interference.

4. High and low-temperature resistance, and flame resistance.

5. Stable chemical changes, high stability and reliability.

6. Providing more solutions for related products can reduce assembly time and errors, and improve the service life of related products.

Flex on board refers to the ability of flexible circuit boards to be adjusted and adapted in different shapes, angles and sizes during the design and manufacturing process. This feature allows FPCs to be efficiently routed in tight spaces, meeting the need for miniaturization and lightweighting of electronic devices. For example, FPCs can be applied in curved or irregularly shaped devices, enhancing design freedom and feasibility.

Overview of flexboard Industry

In the flexboard industry chain, the upstream mainly covers eight categories of core raw materials, specifically including flexible copper-clad laminate (FCCL), cover film, components, shielding film, adhesive paper, steel sheet, plating additives and dry film. Among them, the sheet film of FCCL is mainly composed of polyimide film (PI), polyester (PET), polyethylene naphthalene dicarboxylate (PEN), liquid crystal display polymer (LCP) and other polymer materials plastic film. The midstream segment focuses on FPC manufacturing and processing, while the downstream is widely used in various fields, such as display/touch modules, fingerprint identification modules, camera modules, etc., and ultimately serves a variety of industries, such as consumer electronics, communication equipment, automotive electronics, industrial control and medical, aerospace and so on.

With the electrification and intelligence of the automotive industry continues to promote,flexboard in the bending, weight reduction and automation degree and other aspects of the advantages of the more and more significant, and its application in the field of automotive is also becoming more and more extensive. Whether it is lights, display modules, or BMS/VCU/MCU three major power control systems, sensors, and advanced auxiliary systems and other scenarios,can be seen FPC's figure. In particular, the booming development of new energy vehicles, but also greatly promote the demand for FPC on board power battery.

The specific application of flexboard in new energy vehicles

As an important part of the new energy vehicle BMS system,the acquisition line is responsible for monitoring the voltage and temperature of the new energy power battery cell,data acquisition and transmission, and overcurrent protection function,can protect the automotive power battery cell,and in the case of anomalous short-circuit automatic disconnection.

In the past, the new energy vehicle power battery collection line mainly adopts the traditional copper wire harness programme.However,this programme has a large space occupation, low degree of automation and other issues. In contrast, FPC, with its highly integrated, ultra-thin thickness and ultra-softness,shows obvious advantages in safety, lightweight and layout and so on. In addition, the thickness of FPC is thin, the battery pack structure can be customised, the assembly can be placed directly through the robot arm, the degree of automation is high, very suitable for large-scale mass production.Therefore, the trend of FPC replacing copper wire harness is becoming more and more obvious.

In the early stage of industry introduction,due to the high cost and the strict requirements of reliability in the field of automotive electronics, most power battery companies have a wait-and-see attitude. However,with the excellent performance of FPC and the cost reduction brought about by large-scale production, the process of FPC replacing traditional wiring harnesses has accelerated significantly. Nowadays, the first echelon of domestic power battery enterprises, including Ningde Times and BYD, have already applied FPC in bulk in the pack segment, while Tesla, Guoxuan Gaoke, AVIC Li-power, Tafel, Xinwanda, Vonergy, etc., have also started to apply FPC. it can be said that the FPC solution has already become the first choice for the majority of the new new energy automobile models.

In addition,flexboard is also developing in the direction of CCS (Cells Contact System, integrated busbar, wiring harness board integrated parts) integration.CCS products are composed of FPC, plastic structural parts, copper and aluminium rows, etc. Through laser welding, multiple electric cores are connected in series and parallel, and connected with copper and aluminium rows and plastic structural parts through flexboard, so as to constitute the electrical connection and signal detection structural components.

The difference between flexible circuit board and rigid board

PCB flexible circuit board and rigid board are two common types of boards in the electronics industry, playing different roles in board design and manufacturing processes. Although their names are similar,their design and manufacturing methods are different.

1.Materials

Flex board is a type of flexboard made of flexible materials such as polyester film, polytetrafluoroethylene film, etc.

Rigid board is a circuit board made of hard materials such as glass fiber-reinforced resin.

2.Application scope

Due to its flexibility, flexboards are particularly suitable for applications that require bending and bending, such as in wearable devices, mobile phones, car interiors, car bodies, and certain high-precision electronic devices.

Rigid boards are commonly used in applications that require greater strength and robustness, such as computer internal structures, mechanical and industrial products, and complex circuit manufacturing.

3.Electrical performance

Although flexboards can still function under bending or twisting, they may have limitations in electrical performance, such as lower signal transmission speed and impedance control stability compared to hard boards.

The electrical performance of rigid boards is more stable and reliable, especially in high-density wiring applications.

Compared with traditional rigid boards,flexboard has high flexibility and flexibility,adapting to various complex shapes and spatial layouts,making circuit board design more flexible and diverse. It has the advantages of small size and light weight,greatly reducing the size and weight of the device,and making it more convenient to carry electronic devices.