The thermal conductivity of copper base PCB is a heat dissipation performance parameter of copper base PCB, which also measures the efficiency of copper substrate in conducting heat from the circuit level through the thermal insulation layer. Its thermal conductivity can be between 2w/m. k-398w/m. k.

The thermal conductivity of copper base PCB is many times better than that of the aluminum substrate and iron substrate, and it is suitable for heat dissipation and building decoration industries of high-frequency circuits, areas with high and low-temperature changes, and precision communication equipment. The circuit board made of copper-based PCB has advantages such as good thermal conductivity, electrical insulation performance, and mechanical processing performance. The substrate material is generally copper plate, which can provide better thermal conductivity. Its heat dissipation effect is also many times better than aluminum and iron.

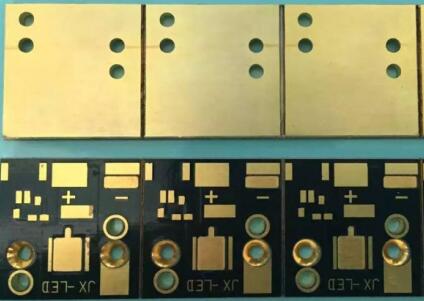

Characteristics of copper base PCB

1. The thermal insulation layer is one of the core parts of the copper base PCB, so its copper foil thickness is mostly 35um to 280um, which can achieve a strong current carrying capacity. Compared with the aluminum substrate, the main material of the aluminum substrate is aluminum, which has a high thermal resistance value and does not dissipate heat significantly during use. It is recommended to use copper-based PCB to achieve better heat dissipation and ensure product stability.

2. Among circuit components, copper base PCB is a common heat dissipation substrate, because in the circuit and circuit component products with high power density, some substrates have poor aging resistance, and mechanical and thermal stress resistance, while copper base PCB can play a good role in its good heat dissipation performance.

The high-temperature resistance of copper base PCB is about 300-400 degrees Celsius, and its temperature is related to the quality of solder paste and lamp beads. Generally, the welding time is around 30-50 seconds without damage to the components. The actual tin melting time is only 10 seconds, mainly due to preheating and heat dissipation issues.

The difference between copper substrate and ceramic substrate

1. Differences in material properties

Copper base PCB is a substrate mainly made of copper, which has good thermal conductivity and conductivity. Copper has excellent thermal conductivity and can effectively dissipate heat, making it suitable for high-power electronic devices. In addition, the copper base PCB also has good conductivity and can provide stable current transmission. Ceramic substrates, on the other hand, are mainly composed of ceramic materials, which have excellent insulation and high-temperature resistance. Ceramic materials have good insulation properties and can effectively prevent current leakage, making them suitable for high-frequency electronic devices. In addition, ceramic-based panels also have good high-temperature resistance and can work stably in high-temperature environments.

2. Differences in manufacturing processes

The manufacturing process of copper base PCB is relatively simple, mainly including steps such as cutting, cleaning, etching, and drilling of copper foil. Copper foil can be patterned through chemical etching to form structures such as wires and solder pads. The manufacturing process of ceramic substrates is relatively complex, mainly including the preparation, molding, sintering and other steps of ceramic materials. Ceramic materials need to undergo high-temperature sintering to form a dense structure to provide good insulation and high-temperature resistance.

3. Differences in application fields

Due to its excellent thermal conductivity and conductivity, copper-based PCBs are suitable for heat dissipation and current transmission in high-power electronic devices, making them widely used in fields such as power electronics, automotive electronics, and LED lighting. Ceramic substrates, due to their excellent insulation and high-temperature resistance, are suitable for signal transmission in high-frequency electronic devices and applications such as RF power amplifiers. Therefore, they are widely used in communication, radio frequency equipment, satellite communication, and other fields.

Copper base PCB is a circuit board with copper foil as the conductive layer and substrate as the support, suitable for high-precision and high-frequency circuit applications. The signal transmission performance of copper-base PCB is more stable and suitable for high-frequency circuit applications.